Makita 7104L chain mortiser User Manual

User Manual

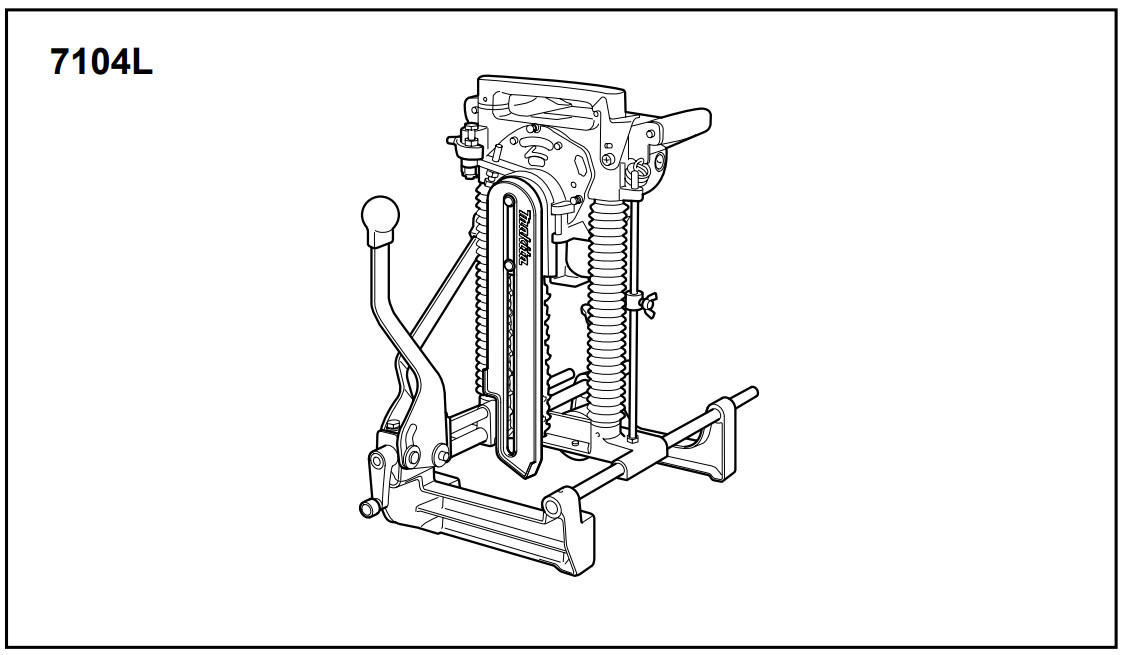

Explanation of general view

| 1-1. Wing bolt 1-2. Stopper pole 1-3. Stopper 2-1. Lock-off button 2-2. Switch trigger 3-1. Adjusting screw 3-2. Chain bar 3-3. Chain cover 3-4. Hex bolt 4-1. Arrow 4-2. Sprocket 4-3. Hex bolt 6-1. Lever (A) 6-2. Vise lever |

7-1. Setting handle 7-2. Front vise 8-1. Indicator plate 8-2. Indication plate 8-3. Cutting line (A) 8-4. Cutting line (B) 9-1. Hook 10-1. Hex bolts 10-2. Gauge plate 10-3. Travel distance (D) 10-4. Lever (B) 11-1. Lever (C) 12-1. Adjusting hex bolt for No. 1 set position |

6-3. Rear vise 12-2. Lever (C) 12-3. Adjusting hex bolt for No. 2 set position 13-1. Original position 13-2. No.1 set position 13-3. No.2 set position 13-4. Indication plate 13-5. Ruler 14-1. Front base 16-1. Limit mark 17-1. Brush holder cap 17-2. Screwdriver |

SPECIFICATIONS

| Model | 7104L | |

| Capacities | Max. hole length (Longitudinal) | 130 mm |

| Max. hole depth | 155 mm | |

| Width of the applicable workpiece | 80 mm – 308 mm | |

| Chain speed | 300 m / min | |

| Dimensions (L x W x H) | 512 mm x 298 mm x 513 mm | |

| Net weight | 17.3 kg | |

| Safety class | Class I | |

- Due to our continuing program of research and development, the specifications herein are subject to change without notice.

- Specifications may differ from country to country.

- Weight according to EPTA-Procedure 01/2003

Intended use

The tool is intended for cutting mortise in wood.

Power supply

The tool should be connected only to a power supply of the same voltage as indicated on the nameplate, and can only be operated on a single-phase AC supply. This tool should e grounded while in use to protect the operator from electric shock. Use only three-wire extension cords which have three-prong grounding-type plugs and three-pole receptacles which accept the tool’s plug.

Noise

The typical A-weighted noise level is determined according to EN61029:

Sound pressure level (LpA) : 90 dB(A)

Sound power level (LWA) : 103 dB(A)

Uncertainty (K) : 3 dB(A)

Vibration

The vibration total value (tri-axial vector sum)

determined according to EN61029:

Vibration emission (ah) : 2.5 m/s2 or less

Uncertainty (K) : 1.5 m/s2

- The declared vibration emission value has been measured in accordance with the standard test method and may be used for comparing one tool with another.

- The declared vibration emission value may also be used in a preliminary assessment of exposure.

WARNING:

- The vibration emission during actual use of the power tool can differ from the declared emission value depending on the ways in which the tool is used.

- Be sure to identify safety measures to protect the operator that is based on an estimation of exposure in the actual conditions of use (taking account of all parts of the operating cycle such as the times when the tool is switched off and when it

For European countries only

EC Declaration of Conformity

We Makita Corporation as the responsible manufacturer declares that the following Makita machine(s):

Designation of Machine:

Chain Mortiser

Model No./ Type: 7104L

are of series production and Conforms to the following European Directives: 2006/42/EC

And are manufactured in accordance with the following standards or standardized documents:

The technical documentation is kept by our authorized representative in Europe who is:

Makita International Europe Ltd.

Michigan Drive, Tongwell,

Milton Keynes, Bucks MK15 8JD, England

30.1.2009

Director

Makita Corporation

3-11-8, Sumiyoshi-cho,

Anjo, Aichi, 446-8502, JAPAN

General Power Tool Safety

Warnings

Save all warnings and instructions for future reference.

ADDITIONAL SAFETY RULES

- Use this tool only to cut holes in wood.

- This tool is for cutting holes in flat-surfaced wood. Never use it for cutting holes in a log.

- Wear ear protectors.

- Handle the cutter chain carefully; it is very sharp.

- Place the workpiece on wood blocks or short beams to prevent the cutter chain from hitting the ground, floor, etc., causing damage to the cutter chain at the time of hole breakthrough.

- Check the cutter chain carefully for cracks or damage before operation.

Replace cracked or damaged cutter chain immediately. - Secure the tool to the workpiece firmly.

- Inspect for and remove nails or foreign matter from the workpiece before operation.

- Do not operate the tool with the safety cover open.

- Do not wear gloves during operation.

- Keep hands away from moving parts.

- Remove the tool from the workpiece after operation to keep it from falling off and possibly causing injury.

- Do not abuse the cord. Never yank the cord to disconnect it from the receptacle. Keep cord away from heat, oil, water and sharp edges.

- PROPER GROUNDING. This tool should be grounded while in use to protect the operator from electric shock.

- EXTENSION CORDS. Use only three-wire extension cords which have three-prong grounding-type plugs and three-pole receptacles which accept the tool’s plug.

Replace or repair damaged or worn cord immediately.

SAVE THESE INSTRUCTIONS.

FUNCTIONAL DESCRIPTION

CAUTION:

- Always be sure that the tool is switched off and unplugged before adjusting or checking the function on the tool.

Adjusting the depth of cut

Fig.1

Loosen the wing bolt on the stopper. Move the stopper to

the desired position and tighten the wing bolt. When tightened, the tip of the wing bolts should contact the flat surface of the stopper pole. The numbers indicated on

the stopper pole are in cm units (3 mm per graduation).

Switch action

Fig.2

- Before plugging in the tool, always check to see that the switch trigger actuates properly and returns to the “OFF” position when released.

To prevent the switch trigger from being accidentally

pulled, a lock-off button is provided. To start the tool, push the lock-off button and pull the switch trigger. Release the switch trigger to stop.

ASSEMBLY

CAUTION:

- Always be sure that the tool is switched off and unplugged before carrying out any work on the tool.

Installing or removing cutter chain

Fig.3

WARNING:

- Always be sure that the tool is switched off and unplugged before installing or removing the cutter chain.

- Always close the chain cover after installing, removing or adjusting the cutter chain.

To install the cutter chain, open the chain cover. Loosen the hex bolt securing the chain bar and the adjusting screw.

Orient the cutters in the direction of the arrow on the tool (rotational direction). Attach the cutter chain to the sprocket first and then to the chain bar. Semi-tighten the hex bolt.

Fig.4

Turn the adjusting screw to increase the tension on the cutter chain. Pull the middle of the cutter chain lightly.

When there is a clearance of approx. 5 – 6 mm between the chain bar and the cutter chain, the tension on the cutter chain is adequate.

Fig.5

After adjusting the tension, tighten the hex bolt firmly to secure the chain bar. Additionally, tighten slightly the adjusting screw. Close the chain cover.

To remove the cutter chain, follow the installation procedures in reverse. Securing tool to the workpiece

Fig.6

Fig.7

Loosen the vise lever and move the rear vise backward.

Place the tool on the workpiece so that the front vise contacts the side of the workpiece. Move the rear vise forward until the distance between the rear vise and the workpiece is 3 – 8 mm. Tighten the vise lever to secure the rear vise. Move the tool so that the “0” on the indication plate is aligned with the cutting line (A). Push the lever (A) down fully to secure the workpiece.

Turn the setting handle until the front edge of the yellow indicator plate is aligned with the cutting line (B).

Fig.8

OPERATION

Fig.9

Grasp firmly the grips on either side. Switch on the tool and wait until the cutter chain attains full speed. Then release the hook and lower the tool head to cut in the workpiece. Do not apply excessive pressure to the tool. This may not only decrease the working efficiency but also cause a dangerous reaction. Feed slowly at the beginning of a cutting operation, at the time of hole breakthrough, and when cutting a knot in the workpiece.

After cutting, gently raise the tool head until you can hook the tool head back onto the hook. Then switch off the tool. Raise the lever (A) and remove the tool from the workpiece.

WARNING:

- Always hook the tool head back onto the hook when not operating the tool.

- Never attempt to cut a twisted or warped workpiece to which the tool is not secured firmly to.

Adjusting indicator plate and indication plate

The yellow indicator plate and indication plate are factories adjusted for the standard equipped cutter chain 16.5 mm. If the alignment is off, for some reason, or when using another size cutter chain, loosen the screws and adjust the yellow indicator plate and indication plate.

Enlarging hole

- Transverse (width) enlargement

Fig.10

A hole can be enlarged transversely by adjusting the gauge plate. Max. expansion of hole width is 15 mm.

Example:

When cutting a hole 25 mm wide using a cutter chain 16.5 mm, proceed as follows:

- Push the lever (B) away from you.

Loosen the hex bolts securing the gauge plate. - Adjust the gauge plate so that the travel distance (D) is 8.5 mm; that is, 25 mm – 16.5 mm = 8.5 mm. Tighten the hex bolts to secure the gauge plate.

- Cut the first hole with the lever (B) pushed away from you. Then pull the lever (B) toward you and cut again to enlarge the hole.

NOTE:

- The gauge plate is factory adjusted for cutting a hole 30 mm wide.

Longitudinal (length) enlargement

Hole length can be determined in three steps shown in the table below.

| Cutter chain position | Hole length to be cut |

| Original position | 52.5 mm |

| No.1 set position | 52.5 mm – 105 mm |

| No.2 set position | 77.5 mm – 130 mm |

NOTE:

- A hole a little longer than predetermined may be cut depending upon the cutter chain tension.

- The adjusting hex bolts are factory adjusted for cutting holes 90 mm long in the No.1 set position and 120 mm long in the No.2 set position.

Push down the right-hand grip while raising the left-hand grip. Make sure that the adjusting hex bolt slips into place securely.

Fig.11

Loosen the hex nut securing the adjusting hex bolt. Turn the adjusting hex bolt until the cutter chain reaches the desired position, then tighten the hex nut.

Fig.12

WARNING:

- When using pressure to turn the adjusting hex bolt or hex nut, be careful not to allow the adjusting hex bolt to slip off the set position.

To bring the cutter chain back to the perpendicular(original) position, pull the lever (C) toward you while pressing down on the right-hand grip and slightly raising the left-and grip, and moving the cutter chain back to its original position.

When cutting a hole, first use the perpendicular position, then the No.1 set position, and finally the No.2 set position.

Always safely hook the tool head back onto the hook when changing the cutter chain position.

Fig.13

When enlarging a hole both transversely and longitudinally, cut the holes in the order indicated from No.(1) to (6) as shown. This makes for more easy and more efficient hole enlargement.

Fig.14

WARNING:

- Never attempt to enlarge a hole with the cutter chain still within the hole. This will cause unstable and dangerous operations.

- Never angle the cutter chain when cutting the first hole, or a dangerous kickback may result. Always have the cutter chain set to the perpendicular position when cutting the first hole.

Lap joints up to 130 mm can be cut with this tool.

Fig.15

NOTE:

- Lap joints can be cut only on the front (the side away from you) of the workpiece.

MAINTENANCE

CAUTION:

- Always be sure that the tool is switched off and unplugged before attempting to perform inspection or maintenance.

- Never use gasoline, benzine, thinner, alcohol, or the like. Discoloration, deformation, or cracks may result.

Replacing carbon brushes

Fig.16

Remove and check the carbon brushes regularly.

Replace when they wear down to the limit mark. Keep the carbon brushes clean and free to slip in the holders.

Both carbon brushes should be replaced at the same time. Use only identical carbon brushes.

Use a screwdriver to remove the brush holder caps.

Take out the worn carbon brushes, insert the new ones and secure the brush holder caps.

Fig.17

Lubrication

After use, remove dirt, chips and foreign matter adhering to the tool. Then oil the moving parts (especially cutter chain) and the contact portions.

To maintain product SAFETY and RELIABILITY, repairs, any other maintenance or adjustment should be performed by Makita Authorized Service Centers, always using Makita replacement parts.

ACCESSORIES

CAUTION:

- These accessories or attachments are recommended for use with your Makita tool specified in this manual. The use of any other accessories or attachments might present a risk of injury to persons. Only use accessory or attachment for its stated purpose.

If you need any assistance for more details regarding these accessories, ask your local Makita Service Center. - Cutter chain

- Chain bar for 30 mm

- Sprocket 4 for 30 mm

- Oil supply (100 cc)

Makita Corporation

Anjo, Aichi, Japan

www.makita.com