Honeywell TB6575 Digital Fan Coil Thermostats Instruction Manual

Honeywell TB6575 Digital Fan Coil Thermostats Instruction Manual

PRODUCT DESCRIPTION

The TB6575 and TB8575 are a family of Digital Fan Coil thermostats for residential and commercial applications such as hotels, condominiums, school classrooms, etc.

Four models are available for your application:

- TB6575A1016 – 2-pipe or 4-pipe with seasonal/ manual/automatic heat/cool changeover; 120/240 Vac.

- TB6575B1000 – 2-pipe only with seasonal or manual heat/cool changeover; 120/240 Vac.

- TB6575C1016 – 2-pipe or 4-pipe with seasonal/ manual/automatic heat/cool changeover; 120/240/ 277 Vac.

- TB8575A1016 – 2-pipe or 4-pipe with seasonal heat/ cool changeover; 24Vac.

All four models are suitable for multiple applications. Changes in output wiring and external links between wiring terminals allow you to configure the thermostat for the appropriate application.

The applications that are available are:

- Heating or Cooling only

- Two pipes: Heat or Cool with Manual Changeover

- Two pipes: Heat or Cool with Seasonal Changeover (requires optional pipe sensor)

- Two pipes: Heat or Cool with Auxiliary Heat and Manual or Seasonal Changeover (requires optional pipe sensor)

- Four pipes: Mixed Manual and Auto Changeover

- Four pipes: Manual Changeover

- Four pipes: Auto Changeover

The fan is controlled from the thermostat. The Low, Medium, High, or Auto fan settings are easily made with a press of a key Valves and auxiliary electric heaters can be controlled using a relay or contactor controlled by the system switch.

FEATURES

- Simple, intuitive user interface.

- Pre-installed lead wires for fast installation (TB6575A, TB6575B and TB6575C models only)

- Backlight display permits easy viewing in any light.

- Four buttons allow manual control of system operation, fan speed, and temperature setpoint adjustment.

- Digital display of ambient temperature, setpoint, heating or cooling mode, fan status, and remote setback

- Proportional plus Integral (P+I) control algorithm for precision temperature regulation.

- Single Setpoint and Heat/Cool setpoint methods for 4-pipe auto changeover.

- Adjustable maximum heating and minimum cooling setpoint limits using range stops.

- EEPROM permanently retains user settings, including setpoints, during power loss (no batteries required).

- Selectable °C or °F display via Setup button on thermostat.

- Displayable pipe sensor temperature readout to aid in troubleshooting.

- Selectable to allow the fan motor to always begin on high speed to ensure sufficient torque at startup.

- Option to wire a remote indoor temperature sensor.

- Freeze protect algorithm turns on heat when needed.

- Economy Setback options via dry contact or Activity Sensing

- Advanced fan control with VersaSpeed™ fan ramp algorithm and Auto Fan Reset.

SPECIFICATIONS

Supply Voltages:

TB6575A1016 and TB6575B1000:

- 120 Vac ±10% at 50/60Hz

- 240 Vac -15% to +10% at 50/60Hz

TB6575C1016:

- 120 Vac ±10% at 50/60Hz

- 240 Vac -15% to +10% at 50/60Hz

- 277 Vac ±10% at 50/60Hz

TB8575A1016:

- 20 to 30 Vac at 50/60Hz (using 24 Vac, Class 2, NEMA rated transformer)

Safety Fuse: 15 A, 350V. If the safety fuse blows, the thermostat must be replaced. The fuse is not field replaceable.

Electrical Ratings: (see Table 1).

Table 1. Electrical Ratings.

| Component | Amps (inductive) for: | |||

| 24 Vac | 120 Vac | 240 Vac | 277 Vac | |

| Fan Relay | 1.0 A | 6.0 A | 3.0 A | 2.4 A |

| Heat/Cool Relay | 1.0 A | 1.0 A | 1.0 A | 1.0 A |

Environmental Ratings:

Temperature:

Operating Range: 18°C to 49°C (0°F to 120°F).

Shipping and Storage Range: -29°C to 49°C (-20°F to 120°F).

Humidity: 5% to 90% RH, non-condensing.

Onboard Temperature Sensor:

Type: 10K NTC

Working Range: 18°C to 49°C (0°F to 120°F)

Display Range: 0°C to 37°C (32°F to 99°F)

Accuracy ±2.0°F at 70°F

Remote Temperature Sensor (optional):

Type: 20K NTC

Working Range: 18°C to 49°C (0°F to 120°F)

Display Range: 0°C to 37°C (32°F to 99°F)

Accuracy ±2.0°F at 70°F

Remote Pipe Sensor (optional):

Type: 20K NTC

Working Range: 0°C to 93°C (32°F to 199°F)

Display Range: 0°C to 93°C (32°F to 199°F)

Accuracy ±5.0°F over the temperature sensing range

Remote Setback Input: Dry contact, maximum resistance of 100 ohms. TB6575 – 9Vdc, < 4 mA; TB8575 – 16 Vdc, < 5 mA. Note Electrical WARNING on page 3.

Remote Setback Range:

- Heating: 10°C to 21°C (50°F to 70°F).

- Cooling: 22°C to 32°C (72°F to 90°F).

Enclosure: Plastic (cover, sub-base, and optional adaptor plate)

Junction Box Mounting: Direct mounting on a horizontal single gang NEMA 2 x 4 in. surface mount electrical box, or on 4 x 4 in. box or vertical 2 x 4 in. surface mount electrical box with the optional 50033847-001 adapter plate.

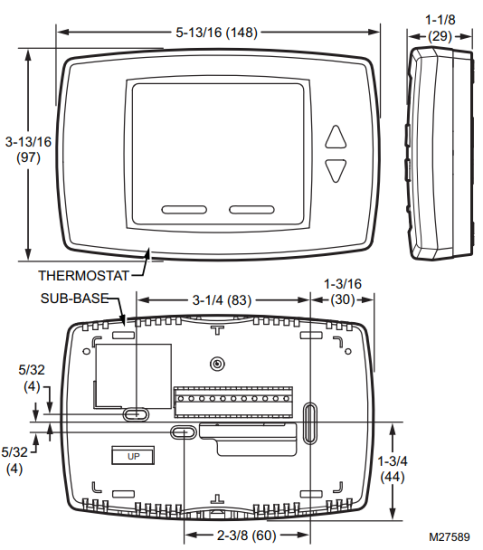

Dimensions: See Fig. 1 on page 3.

Wiring: 11 screw-in terminals located on the sub-base capable of accepting up to 2 x 18 AWG (0.8 sq. mm), 1 x 16 AWG (1.3 sq. mm), or 1 x 14 AWG (2.1 sq. mm) wires. Accepts stranded or unstranded 14-28 gauge wire.

NOTES

- The TB6575A1016 and TB6575C1016 models are pre-fitted with color-coded fly leads (16 AWG) attached to seven terminals.

- The TB6575B1000 model is pre-fitted with colorcoded fly leads (16 AWG) attached to six terminals.

- The TB8575A1016 model does not have fly leads attached to any terminals.

- See Table 3 on page 5 for fly lead usage.

Minimum Operational Life (at maximum load):

Thermostat contacts: 100,000 cycles

Approvals:

CSA Certified C/US for Canada and the U.S.A. Meets the same requirements as UL-873 and UL 1/4 HP.

FCC Part 15 Class B

Accessories:

- 50033847-001 – Adapter plate for mounting on a vertical 2 x 4 in. single-gang or double-gang NEMA standard vertical switch box (6 1/4 in. (158 mm) x 5 1/ 16 in. (128 mm) x 13/22 in. (10 mm)).

- TR21 – 20K Ohm NTC Non-Linear Remote temperature sensor. Other acceptable remote temperature sensors are —

- 20K Ohm: C7041B2005, C7041B2013, C7041C2003, C7041P2004, C7770A1006, C7772A1004, and C7772A1012

- 10K Ohm (for averaging only): TR21-A

- PS20 (535-34AB08-203) – Remote pipe sensor (20K Ohm)

- W6380B1005 – Fan Coil Unit Relay Control Center

- WSK-24 – Wireless Occupancy Solution (Receiver, occupancy sensor and door sensor)

Models, applications, and features:

Table 2 identifies the applications and features of each model.

Models |

Applications |

Features | ||||||||

| Heat/Cool/ Auto | Pipes | Voltage | Number of Relaysa | Energy Savings Input | Fan: On, Auto, or 3 speed | Manual/ Auto Changeover | Remote Sensor | Back Light | Pipe Sensorb | |

| TB6575A1016 | All | 2 or 4 | 120 or 240 Vac | 5 | Yes | Yes | Yes | Yes | Yes | Yes |

| TB6575B1000 | Heat or Cool | 2 | 120 or 240 Vac | 4 | ||||||

| TB6575C1016 | All | 2 or 4 | 120, 240 or 277 Vac | 5 | ||||||

| TB8575A1016 | All | 2 or 4 | 24 Vac | 5 | ||||||

Table 2. Applications and Features

a The five relays are wired via terminals W, Y, Gh, Gm, and Gl. Relay 1 Controls Heat open (W) or Cool open (Y). Relay 2 controls Cool open or Electrical heater output (Y/A). Relays 3, 4, and 5 ontrol the High, Medium, and Low fan speeds respectively (Gh, Gm, and Gl).

NOTE: In 2-pipe configurations without Auxiliary Heat, only 4 relays are used; relay 2 (Y/A) is not used.

b Pipe sensor is required for 2 pipe auto changeover and 2 pipe auxiliary heat applications.

Dimensions

Fig. 1. Dimensions in inches (mm).

INSTALLATION

When Installing this Product…

- Read these instructions carefully. Failure to follow them could damage the product or cause a hazardous condition.

- Check the ratings given in the instructions and on the product to make sure the product is suitable for your application.

- Installer must be a trained and experienced service technician.

Risk of electrical shock.

Can cause severe injury, property damage or death.

Disconnect power supply before installation and before servicing.

IMPORTANT

The thermostats are line voltage powered devices. All wiring must comply with national and local electrical codes, ordinances and regulations. Provide disconnect means and overload protection, as required.

The TB8575A1016 thermostat must be powered by an Approved 24 Vac, Class 2, NEMA rated transformer (such as a W6380 Relay Control Center).

Location

The thermostats are the temperature control element in a fan coil or air-conditioning system. They must be located about 1.5m (5 ft.) above the floor, in a position with good air circulation, to sense room temperature.

IMPORTANT

Do not mount the device where it can be affected by:

- Drafts or dead spots behind doors or in corners.

- Hot or cold air from ducts.

- Radiant heat from the sun or appliances.

- Unheated (uncooled) areas such as an outside wall behind the thermostat.

- Concealed pipes or chimneys.

Mounting and Wiring

Equipment damage hazard.

Operation at low temperatures can cause fan coil damage.

This thermostat is not a safety device. Do not use it where the space temperature is outside of the device operating range.

A display of two dashes, – –, for the Room Temp display indicates a sensor failure or a temperature outside of the thermostat operating range of 18°C to 49°C (0°F to 120°F). With – – displayed, the thermostat ceases to operate. When the temperature returns to within its operating limits, the thermostat returns to operation.

The optional freeze protect feature should be used if low temperatures can occur.

The thermostat must be mounted flush to the wall. The thermostat can be mounted directly to a 2 x 4 in. horizontal junction box (see Fig. 2 ). An optional adaptor plate (50033847-001) can be used with a 4 x 4 in. or a vertical junction box for which mounting screws are supplied (see Fig. 3).

Fig. 2. Mounting sub-base and thermostat to 2 x 4 in. junction box.

Fig. 3. Mounting sub-base and thermostat using the adaptor plate (50033847-001).

- Prepare the supply wires:

- a. Mounting on a 4 x 4 in. or vertical 2 x 4 in. junction box:

- Feed the supply wires through the junction box and the opening in the adaptor plate.

- Affix the adaptor plate to the junction box using the screws provided.

- b. Mounting on a horizontal 2 x 4 in. junction box: Feed the supply wires through the opening of the junction box.

- a. Mounting on a 4 x 4 in. or vertical 2 x 4 in. junction box:

- Attach the supply wires:

- a. For the TB6575A1016,TB6575B1000 and TB6575C1016 models:

- Push the fly lead wires through the wiring access hole in the sub-base.

- Attach the fly lead wires to the supply wires using wire nuts (not provided).See Table 3 on page 5 for terminal and lead identification.

- Push the fly lead and supply wires back into the junction box.

- b. For the TB8575A1016 model (which does not have pre-wired fly leads):

- Attach the supply wires directly to the terminals on the sub-base. See Table 3 on page 5 for terminal identification.

- Push the supply wires back into the junction box.

- a. For the TB6575A1016,TB6575B1000 and TB6575C1016 models:

- Mount the sub-base:

- a. Mounting on a 4 x 4 in. or vertical 2 x 4 in. junction box: Align the two holes at the top edges of the subbase with the two pins on the adaptor plate. Attach the sub-base to the adaptor plate using the screws provided.

- b. Mounting on a horizontal 2 x 4 in. junction box: Attach the sub-base to the junction box using the screws provided.

- Thoroughly check the wiring to the sub-base before finally mounting the thermostat on the wall.

- Center the thermostat body over the sub-base, and press down firmly to engage the four tabs on the sub-base and snap the thermostat body into place.

- Use the provided safety screw to secure the thermostat main body to the sub-base.

- If using the adaptor plate, press the adaptor plate screw cover into place.

Terminal Wiring

Table 3 provides the terminal wiring for each model and application.

NOTE: The TB6575A1016,TB6575B1000 and TB6575C1016 models have color coded fly leads attached to the terminals. Refer to Table 3 for the color codes.

The Terminal Identifiers in Table 3 have the following meaning:

- C: Common 24 Vac

- Gh: High speed fan relay

- Gl: Low speed fan relay

- Gm: Medium speed fan relay

- L: Line voltage power (120/240/277 Vac)

- N: Line voltage ground (120/240/277 Vac)

- Ps: Pipe sensor (optional)

- R: 24 Vac power

- Rs: Remote sensor (optional)

- SB: Remote setback (optional)

- Sc: Ground (required if remote sensor, pipe sensor, and/or remote setback are connected)

- W/Y: W = Heating; Y = Cooling (2 pipe only)

- Y/A: Y = Cooling; A = Electrical heater output

| Model | Application | Terminals | |||||||||||||||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | |||||||||||||

| TB6575A1016 — 120/240 Vac; TB6575C1016 — 120/240/277 Vac | |||||||||||||||||||||||

| Terminal Identifier | L | W/Y | Y/A | Gl | Gm | Gh | N | Rs a | Sc b | SB c | Ps d | ||||||||||||

| Fly lead wire color | Black | Orange | Yellow | Red | Blue | Brown | White | None e | |||||||||||||||

| 2 pipes; Heat only | W | O | Rh | O | |||||||||||||||||||

| 2 pipes; Cool only | Y | O | R | O | |||||||||||||||||||

| 2 pipes; Heat or Cool with Manual Changeover | W/Y | O | R | O | |||||||||||||||||||

| 2 pipes; Heat or Cool with Seasonal Changeover | W/Y | O | R | O | |||||||||||||||||||

| 4 pipes; Heat and Cool with Manual Changeover | W | Y | O | R | O | ||||||||||||||||||

| 4 pipes; Heat and Cool with Auto Changeover | W | Y | O | R | O | ||||||||||||||||||

| 2 pipes; Heat or Cool with Auxiliary Heat | W/Y | A | O | R | O | ||||||||||||||||||

| 4 pipes; Heat and Cool with Manual Changeover or Auto Changeover | W | Y | O | R | O | ||||||||||||||||||

| TB6575B1000 — 120/240 Vac | |||||||||||||||||||||||

| Terminal Identifier | L | W/Y | n/a i | Gl | Gm | Gh | N | Rs a | Sc b | SB c | Ps d | ||||||||||||

| Fly lead wire color | Black | Orange | Red | Blue | Brown | White | None e | ||||||||||||||||

| 2 pipes; Heat only | W | O | R | O | |||||||||||||||||||

| 2 pipes; Cool only | Y | O | R | O | |||||||||||||||||||

| 2 pipes; Heat or Cool with Manual Changeover | W/Y | O | R | O | |||||||||||||||||||

| 2 pipes; Heat or Cool with Seasonal Changeover | W/Y | O | R | O | |||||||||||||||||||

| TB8575A1016 — 24 Vac | |||||||||||||||||||||||

| Terminal Identifierj | R | W/Y | Y/A | Gl | Gm | Gh | C | Rs a | Sc b | SB c | Ps d | ||||||||||||

| 2 pipes; Heat only | W | O | R | O | |||||||||||||||||||

| 2 pipes; Cool only | Y | O | R | O | |||||||||||||||||||

| 2 pipes; Heat or Cool with Manual Changeover | W/Y | O | R | O | |||||||||||||||||||

| 2 pipes; Heat or Cool with Seasonal Changeover | W/Y | O | R | O | |||||||||||||||||||

| 4 pipes; Heat and Cool with Manual Changeover | W | Y | O | R | O | ||||||||||||||||||

| 4 pipes; Heat and Cool with Auto Changeover | W | Y | O | R | O | ||||||||||||||||||

| 2 pipes; Heat or Cool with Auxiliary Heat | W/Y | A | O | R | O | ||||||||||||||||||

| 4 pipes; Heat and Cool with Manual Changeover or Auto Changeover | W | Y | O | R | O | ||||||||||||||||||

Table 3. Terminal Wiring.

- a Rs; Remote sensor is optional.

- b Required when Rs, SB, or Ps is wired.

- c SB; Remote setback is optional.

- d Pipe sensor: Discrete, Analog, or Aquastat®.

- e These terminals (8, 9, 10, and 11) do not have lead wires attached to them.

- f A check mark (ü) indicates the terminal is used in that application. Rs and SB terminal connections are optional. If a terminal is left blank, it is not used in that application.

- g O = Optional

- h R = Required if Rs, SB, or Ps is wired.

- i Terminal 3 is not used on the TB6575B1000 model.

- j The TB8575A1016 model does not have fly lead wires attached to any terminals.

Accessory Wiring

Remote Pipe Sensor Wiring

The remote pipe sensor is used for 2 pipes auto and 2 pipes heat and cool with auxiliary heat changeover. The pipe sensor will sense the temperature in the pipes to tell the thermostat when the system is set for Heat or Cool.

- Check Installer Setup Number (IS) 5 to ensure it is set to the desired value.

- Wire pipe sensor to Sc and Ps terminals.

- Attach pipe sensor to the pipe.

- Insulate pipe sensor, as necessary.

- Change pipe sensor thresholds for cooling or heating by setting Installer Setup Numbers (IS) 6 and 7 to desired values.

Remote Temperature Sensor Wiring

The TR21 is an optional remote temperature sensor that can be used as an alternative to the internal sensor. In addition to the TR21, other sensors that use a 20k Ohm curve may be used as the remote sensor.

Risk of electrical shock. Can cause severe injury, property damage or death.

Disconnect power supply before servicing.

Erratic system operation hazard. Failure to follow proper wiring practices can introduce disruptive electrical interference (noise).

Keep wiring at least one foot away from large inductive loads such as motors line starters, lighting ballasts, and large power distribution panels. Shielded cable is required in installations where these guidelines cannot be met. Ground shield only to grounded controller case.

IMPORTANT

All wiring must comply with local electrical codes and ordinances or as specified on installation wiring diagrams.

- Wall module wiring can be sized from 16 to 22 AWG (1.31 to 0.33 sq. mm) depending on the application.

- The maximum length of wire from the thermostat to a wall module is 1000 ft. (305 m).

- Twisted pair wire is recommended for wire runs longer than 100 ft. (30.5 m).

- Check Installer Setup Number (IS) 4 to ensure it is set to use the remote sensor.

- Wire sensor to Rs and Sc thermostat terminals.

- Push excess wire back into the hole. Plug the hole using non-hardening caulk, putty or insulation to prevent drafts from affecting performance.

- Remove sensor cover.

- Mount sensor to the wall or junction box using the screws and anchors provided.

- Level the sensor for appearance only. Device functions correctly even when not level.

- Replace sensor cover.

NOTE: For complete wiring instructions, please follow the installation instructions provided with the remote sensor.

Sensor Wiring for Temperature Averaging

Fig. 4–Fig. 6 illustrate sensor wiring for temperature averaging applications.

Fig. 4. Wiring four TR21 (20K ohm) sensors.

Fig. 5. Wiring two TR21-A (10K ohm) sensors to provide a temperature averaging network.

Fig. 6. Wiring two TR21 (20K ohm) sensors and one TR21-A (10K ohm) sensor to provide a temperature averaging network.

Thermostat Wiring Diagrams

The figures in this section illustrate typical wiring for:

- TB6575A1016,TB6575B1000 and TB6575C1016 fan coil thermostats, which are 120/240/277 Vac powered. Refer to Fig. 7–Fig. 13,

- TB8575A1016 model, which is 24 Vac powered. Refer to Fig. 14–Fig. 20,

120/240/277 Vac Wiring Diagrams (TB6575A/B/C)

Fig. 7. Two pipes Heat-only wiring diagram (120/240/277 Vac shown).

Fig. 8. Two pipes Cool-only wiring diagram (120/240/277 Vac shown)

Fig. 9. Two pipes (Heat or Cool) Manual Changeover wiring diagram (120/240/277 Vac shown).

Fig. 10. Two pipes (Heat or Cool) Auto Changeover wiring diagram (120/240/277 Vac shown).

Fig. 11. Four pipes (Heat and Cool) Manual/Auto changeover wiring diagram (120/240/277 Vac shown)

Fig. 12. Two pipes (Heat or Cool) with Auxiliary Heat and Manual Changeover wiring diagram (120/240/277 Vac shown).

Fig. 13. Wiring diagram when missing a wire for electromechanical retrofit (120/240/277 Vac shown).

- REMOVE PRE-WIRED WIRE FROM TERMINAL 5 (MID FAN SPEED).

- JUMPER TERMINALS 5 AND 6 (MID AND HIGH FAN SPEEDS). FAN MEDIUM SETTING WILL OPERATE ON HIGH SPEED.

- CONNECT TERMINAL 7 TO THE MID FAN SPEED WIREFROM THE PREVIOUS SYSTEM.

- REWIRE THE PREVIOUS MID SPEED FAN WIRE TO THE NEUTRAL CIRCUIT IN THE SYSTEM.

- CHANGE INSTALLER SETUP IS CODE 9 TO 2 FOR 2 SPEED FAN CONTROL.

24 Vac Wiring Diagrams (TB8575)

For the TB8575A1016 model, a 24 Vac Class 2 NEMA rated transformer must be used.

Fig. 14. Two pipes Heat-only wiring diagram (24 Vac shown).

Fig. 15. Two pipes Cool-only wiring diagram (24 Vac shown).

Fig. 16. Two pipes (Heat or Cool) Manual Changeover wiring diagram (24 Vac shown).

Fig. 18. Four pipes (Heat and Cool) Manual/Auto Changeover wiring diagram (24 Vac shown)

.

Fig. 19. Two pipes (Heat or Cool) with Auxiliary Heat and Manual Changeover wiring diagram (24 Vac shown).

- REMOVE PRE-WIRED WIRE FROM TERMINAL 5 (MID FAN SPEED).

- JUMPER TERMINALS 5 AND 6 (MID AND HIGH FAN SPEEDS). FAN MEDIUM SETTING WILL OPERATE ON HIGH SPEED.

- CONNECT TERMINAL 7 TO THE MID FAN SPEED WIRE FROM PREVIOUS SYSTEM.

- REWIRE THE PREVIOUS MID FAN SPEED WIRE TO THE NEUTRAL CIRCUIT IN THE SYSTEM.

- POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

- CHANGE INSTALLER SETUP IS CODE 9 TO 2 FOR 2 SPEED FAN CONTROL.

Fig. 20. Wiring diagram when missing a wire for electromechanical retrofit (24 Vac shown).

Removing the Thermostat

Risk of electrical shock.

Can cause severe injury, property damage or death.

Disconnect power supply before servicing.

Equipment damage hazard.

Improper removal can damage the thermostat. Carefully follow the thermostat removal directions.

If it is necessary to remove the thermostat from the subbase, refer to Fig. 21 and perform the following steps:

- Turn off the thermostat by pressing the system button until OFF displays.

- Remove the power source from the thermostat.

- Remove the small safety screw at the bottom of the thermostat.

- Use both hands to pull the thermostat straight away from the sub-base.

SETUP

The thermostat provides an LCD display, two buttons below the display for System and Fan control and two adjustment buttons (Up and Down) to the right of the display. See Fig. 23.

Settings, including setpoints, are permanently retained in EEPROM in case of a power outage.

Fig. 22 illustrates all the possible LCD display elements. Only those elements pertinent to the current settings and status (including the text for the two buttons, System and Fan), actually display.

Fig. 22. LCD display with all possible elements shown.

Fig. 23. LCD display showing default screen

Power-up

At power-up, the thermostat’s LCD shows all display segments for two seconds, enters a self-test mode for a few seconds, and then displays the current room temperature (default screen), as shown in Fig. 23.

NOTE: If there is a temperature sensor failure or the temperature is outside of the operating range, the room temperature display shows two dashes, — —.

When the sensor returns to its operating range, the temperature display resumes.

Equipment damage hazard.

Power overload will damage the thermostat.

The thermostat has a safety fuse rated at 15 A/ 250 Vac. If the fuse blows, the thermostat must be replaced. The fuse is not field replaceable.

This fuse is provided as a safety feature to prevent fire if the thermostat is overloaded.

Installer Setup (IS) Mode

To enter Installer Setup Mode:

- Press and hold both the System button (labeled Heat/Cool) and the Up Arrow button for three (3)seconds.

This displays the setup screen on the LCD. See Fig. 24.

NOTE: Exiting Installer Setup Mode is the same as the method for entering setup mode.

Table 4 provides the setup codes (IS codes) and values. To enter the setup parameters:

- Press the System (Heat/Cool) button to cycle through the IS codes, which display in the upper right following the word Setup.

- Press the Up or Down Arrow buttons to cycle through the option values for the currently displayed IS code. The values display in the center of the screen.

- After the desired value displays, press the System button to store your value selection and display the next IS code.

Fig. 24. Installer Setup (IS) mode screen.

Table 4. Installer Setup (IS) Codes and Options.

| IS Code | Code Description | Option Value | Option Description (Default value shown in Bold) | Notes |

| 1 | Line Voltage Selection | 0 | 120 Vac power supply (Default) | |

| 1 | 240 Vac power supply | |||

| 2 | 277 Vac power supply |

| IS Code | Code Description | Option Value | Option Description (Default value shown in Bold) | Notes |

| 2 | System Type | 0 | Heat only | |

| 1 | Cool only | |||

| 2 | Two pipes: Heat or Cool; Manual Changeover | |||

| 3 | Two pipes: Heat or Cool; Seasonal Changeover (requires optional pipe sensor) | |||

| 4 | Four pipes: Manual Changeover | TB6575A,TB6575B and TB6575C only | ||

| 5 | Four pipes: Auto Changeover | TB6575A,TB6575B and TB6575C only | ||

| 6 | Two pipes: Heat or Cool; with Auxiliary Heat (requires optional pipe sensor). | Allows auxiliary heat to turn on when pipes have cold water (TB6575A,TB6575B and TB6575C only). | ||

| 7 | Four pipes: Manual and Auto Changeover (Default) | TB6575A,TB6575B and TB6575C only | ||

| 2.5 | Fan On/Off Selection for Aux Heat On | 0 | Fan ON when Auxiliary Heat is on (Default) | Enables or disables the auto fan operation when Auxiliary Heat is On (TB6575A,TB6575B and TB6575C only). |

| 1 | Fan OFF when Auxiliary Heat is on | |||

| 3 | Valve Output Type | 0 | Valve energized on call for heat or cool (Default) | |

| 1 | Valve de-energized on call for heat or cool | |||

| 4 | Space Sensor Type | 0 | Onboard Sensor (Default) | |

| 1 | Remote Sensor (TR21 or other 20K Ohm sensor) | |||

| 5 | Pipe Sensor Only displays when value 3 or 6 for the System Type in IS code #2 is selected. | 0 | Contact Open = Cool mode; Contact Closed = Heat mode |

|

| 1 | Contact Open = Heat mode; Contact Closed = Cool mode | |||

| 2 | Contact Open = Heat mode; Contact Closed = Cool mode (same as 1) | |||

| 3 | Contact Open = Cool mode; Contact Closed = Heat mode (same as 0) | |||

| 4 | Analog input (Default). NTC20K, whose curve is the same as TR21. Only displays when system type 3 or 6 is selected. | |||

| 6 | Pipe Sensor Threshold for Cooling | 50 to 72 | Range is 50°F to 72°F. Default is 60°F. | Changes to Cool when pipe temperature is below threshold. |

| 7 | Pipe Sensor Threshold for Heating | 75 to 90 | Range is 75°F to 90°F. Default is 80°F. | Changes to Heat when pipe sensor temperature is above threshold. |

| 8 | Temperature Scale | 0 | Degrees Fahrenheit (°F); Default. | |

| 1 | Degrees Celsius (°C). | |||

| 8.5 | Fan Speed at motor start up | 0 | Provide full power when fan motor starts – always starts in high fan speed (Default) | High speed start up ensures that there is enough torque to start the motor and eliminates and motor locking. |

| 1 | Disable – fan will start at speed that is needed as defined by VersaSpeed | |||

| 9 | Number of Fan Speeds | 1 | Single Speed Fan | Low speed only |

| 2 | 2 Speed Fan | Hi and Low speed fans only | ||

| 3 | 3 Speed Fan (Default) | Hi, Med, and Low speed fan | ||

| 9.5 | Fan Control Type | 0 | Constant and Auto (Default) | When fan is in Auto, the fan ramping algorithm, VersaSpeed, is used |

| 1 | Auto only |

| IS Code | Code Description | Option Value | Option Description (Default value shown in Bold) | Notes |

| 10 | Control Method for 4-Pipe Auto Changeover | 1 | Single Setpoint (Default) | Uses switching differential to change between heating and cooling and controls to a single setpoint (Only displayed for system types 5 or 7) |

| 2 | Heat and Cool Setpoints (2 setpoint method) | Uses a deadband of no control and controls to a heat or cool setpoint. (Only displayed for system types 5 or 7) | ||

| 10.5 | Deadband for Heat/ Cool Setpoints | 2 to 9 | Range is 2 to 9. Default is 3. Deadband = minimum distance between heating and cooling setpoints. | Available when Heat and Cool Setpoints are chosen for the control method for 4- pipe Auto (IS 10) |

| Switching Differential for Single Setpoint | 2 to 6 | Range is 2 to 6. Default is 3. Heat switching point = setpoint – switching differential. Cool switching point = setpoint + switching differential. | Available when Single Setpoint is chosen for the control method for 4-pipe Auto (IS 10) | |

| 11 | CPH Value for Heat | 1 to 12 | Range is 1 to 12. Default is 4. | The number selected indicates the maximum times Heating is cycled on per hour (CPH). IS 2 selection is 5. |

| 12 | CPH Value for Cool | 1 to 6 | Range is 1 to 6. Default is 3. | The number selected indicates the maximum times Cooling is cycled on per hour (CPH). |

| 13 | CPH for Auxiliary Electrical Heater | 1 to 12 | Range is 1 to 12. Default is 6. | The number selected indicates the maximum times Auxiliary Heating is cycled on per hour (CPH). |

| 14 | Display Temperature Adjustment | -4 to 4 | Range is -4°F to +4°F; Default is 0°F. | |

| 15 | Temperature Display Mode | 0 | Display Room Temperature | |

| 1 | Display Setpoint | |||

| 2 | Display Temperature and Setpoint; Default. | |||

| 16 | Setpoint Range Stop for Heating | 50 to 90 |

Range is 50°F to 90°F. Default is 90°F. | |

| 17 | Setpoint Range Stop for Cooling | 50 to 90 |

Range is 50°F to 90°F. Default is 50°F. | |

| 18 | Keypad Lockout | 0 | All keys are available (Default) | |

| 1 | The System button (Heat/Cool) is locked out | |||

| 2 | Both the System and Fan buttons are locked out. | |||

| 3 | All buttons are locked out (System, Fan, Up Arrow, and Down Arrow). The LCD displays LOCKED. |

| IS Code | Code Description | Option Value | Option Description (Default value shown in Bold) |

Notes |

| 19 | Remote Setback | 0 | Disabled | |

| 1 | Hotel card enabled N.O. for unoccupied mode with 1 second software delay going from UnOccupied to Occupied; 2 minute delay going from Occupied to UnOccupied. | |||

| 2 | Hotel Card enabled N.C. for unoccupied mode with 1 second software delay going from UnOccupied to Occupied; 2 minute delay going from Occupied to UnOccupied. | |||

| 3 | Hotel Card enabled N.O. for unoccupied mode with 1 second software delay going from UnOccupied to Occupied; 30 minute delay going from Occupied to UnOccupied | |||

| 4 | Hotel Card enabled N.C. for unoccupied mode with 1 second software delay going from UnOccupied to Occupied; 30 minute delay going from Occupied to UnOccupied. | |||

| 5 | Button Press (Default) | Press and hold “Heat/Cool/ Off” button for 3 seconds and thermostat will go into “Economy Setback” | ||

| 20 | Remote Setback for Heating | 50 to 70 |

Range is 50°F to 70°F. Default is 64°F. | Used when the thermostat is in the Unoccupied state. |

| 21 | Remote Setback for Cooling | 72 to 90 |

Range is 72°F to 90°F. Default is 79°F. | |

| 22 | Activity Sensing | 0 | Disabled (Default) | This will be selectable when IS 19 is set to option 0 or 5. If IS 19 is configured for N.O or N.C, activity sensing will not be available. |

| 1 | 4 hour sensing | |||

| 2 | 8 hour sensing | |||

| 3 | 12 hour sensing | |||

| 4 | 16 hour sensing | |||

| 5 | 20 hour sensing | |||

| 6 | 24 hour sensing | |||

| 23 | Freeze Protection | 0 | Disabled | This feature can not activate when the application is Cool only. This function only occurs when System switch is set to OFF. |

| 1 | Enabled (Default) – Stat cycles On Heat when room temperature reaches 40°F (4°C), and disables Heat when room temperature reaches below 46°F (8°C). The LCD displays FREEZE PROTECT | |||

| 24 | Auto Fan Reset | 0 | Inactive (Default) | Auto Fan Reset is not allowed (does not display) when the fan control type is set to Auto Only, (IS code #9 – value 1). |

| 1 | Resets back to Auto after 2 hours. The start time is calculated after the initial call for Heat/Cool is satisfied. Then, the two (2) hour timing begins. | |||

| 2 | Resets back to Auto after 4 hours. The start time is calculated after the initial call for Heat/Cool is satisfied. Then, the four (4) hour timing begins. | |||

| 25 | Purge Cycle Frequency | 0 | No periodic purge (other purges still apply) | Option 1 Default is normally recommended to make sure changeover is detected quickly on spring and fall days. |

| 1 Purge every 2 hours (Default) | ||||

| 2 | Purge every 24 hours | |||

Installer Test (IT) Mode

To enter Installer Test Mode:

- Press and hold both the Up arrow button and the Down Arrow button for three (3) seconds.

This displays all segments of the LCD screen on the LCD.

Table 5 provides the Test codes (IT codes) and values. To enter the IT codes:

- Press the System (Heat/Cool) button to cycle through the IT codes, which display in the upper right above the word Test.

- Press the Up or Down Arrow buttons to cycle through the values for the currently displayed IT code. The values display in the center of the screen.

- After the desired value displays, press the System button to store your value selection and display the next IT code.

NOTE: Exiting Installer Test Mode is the same as the method for entering test mode,

Fig. 25. Installer Test (IT) mode screen.

Table 5. Installer Test (IT) Codes and Options.