Makita DTW1001 Cordless Impact Wrench Instruction Manual

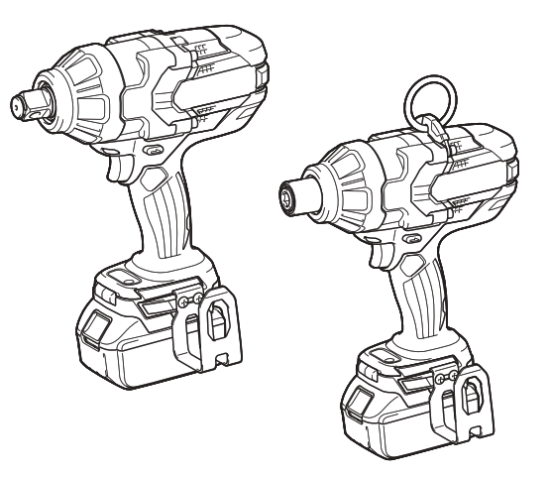

DTW1001

DTW1002

DTW800

(Original instructions)

| Model: | DTW1001 | DTW1002 | DTW800 | ||||

| Fastening capacities | Standard bolt | M12 – M30 | M12 – M24 | ||||

| High tensile bolt | M10 – M24 | M10 – M22 | |||||

| Square drive | 19 mm | 12.7 mm | – | ||||

| Drive shank | – | 11.1 mm Hex. | |||||

| No-load speed | Impact mode (Hard) | 0 – 1,800 min-1 | |||||

| Impact mode (Medium) | 0 – 1,000 min-1 | ||||||

| Impact mode (Soft) | 0 – 900 min-1 | ||||||

| Impacts per minute | Impact mode (Hard) | 0 – 2,200 min-1 | |||||

| Impact mode (Medium) | 0 – 2,000 min-1 | ||||||

| Impact mode (Soft) | 0 – 1,800 min-1 | ||||||

| Overall length | 229 mm | ||||||

| Rated voltage | D.C. 18 V | ||||||

| Battery cartridge | BL1815N, BL1820, BL1820B | BL1830, BL1830B, BL1840, BL1840B, BL1850, BL1850B, BL1860B | BL1815N, BL1820, BL1820B | BL1830, BL1830B, BL1840, BL1840B, BL1850, BL1850B, BL1860B | BL1815N, BL1820, BL1820B | BL1830, BL1830B, BL1840, BL1840B, BL1850, BL1850B, BL1860B | |

| Net weight | 3.4 kg | 3.7 kg | 3.3 kg | 3.6 kg | 3.4 kg | 3.7 kg | |

- Due to our continuing program of research and development, the specifications herein are subject to change without notice.

- Specifications and battery cartridges may differ from country to country.

- Weight, with battery cartridge, according to EPTA-Procedure 01/2003

Intended use

The tool is intended for fastening bolts and nuts.

Model DTW800: The tool is also intended for drilling into wood.

Noise

The typical A-weighted noise level is determined according to EN60745:

Model DTW1001

Sound pressure level (LpA) : 98 dB(A)

Sound power level (LWA) : 109 dB (A)

Uncertainty (K) : 3 dB(A)

Model DTW1002

Sound pressure level (LpA) : 97 dB(A)

Sound power level (LWA) : 108 dB (A)

Uncertainty (K) : 3 dB(A)

Model DTW800

Sound pressure level (LpA) : 95 dB(A)

Sound power level (LWA) : 106 dB (A)

Uncertainty (K) : 3dB(A)

Vibration

The vibration total value (tri-axial vector sum) determined according to EN60745:

Model DTW1001

Work mode: impact tightening of fasteners of the maximum capacity of the tool

Vibration emission (ah) : 15.5 m/s 2

Uncertainty (K) : 2.0 m/s 2

Model DTW1002

Work mode: impact tightening of fasteners of the maximum capacity of the tool

Vibration emission (ah) : 18.0 m/s 2

Uncertainty (K) : 1.5 m/s 2

Model DTW800

Work mode: impact tightening of fasteners of the maximum capacity of the tool

Vibration emission (ah) : 24.0 m/s 2

Uncertainty (K) : 2.0 m/s 2

Work mode: drilling into wood

Vibration emission (ah) : 7.0 m/s 2

Uncertainty (K) : 1.5 m/s 2

NOTE: The declared vibration emission value has been measured in accordance with the standard test method and may be used for comparing one tool with another.

NOTE: The declared vibration emission value may also be used in a preliminary assessment of exposure.

EC Declaration of Conformity

For European countries, only Makita declares that the following Machine(s): Designation of Machine: Cordless Impact Wrench Model No./ Type: DTW1001, DTW1002, DTW800 Conforms to the following European Directives: 2006/42/EC They are manufactured in accordance with the following standard or standardized documents: EN60745 The technical file in accordance with 2006/42/EC is available from Makita, Jan-Baptist Vinkstraat 2, 3070, Belgium 13.5.2015

Yasushi Fukaya

Director

Makita, Jan-Baptist Vinkstraat 2, 3070, Belgium

General power tool safety warnings

WARNING: Read all safety warnings and all

instructions. Failure to follow the warnings and instructions may result in electric shock, fire and/or serious injury.

Save all warnings and instructions for future reference.

The term “power tool” in the warnings refers to your mains-operated (corded) power tool or battery-operated (cordless) power tool.

Cordless impact wrench safety warnings

- Hold power tool by insulated gripping surfaces, when performing an operation where the fastener may contact hidden wiring. Fasteners contacting a “live” wire may make exposed metal parts of the power tool “live” and could give the operator an electric shock.

- Wear ear protectors.

- Check the impact socket carefully for wear, cracks or damage before installation.

- Hold the tool firmly.

- Always be sure you have a firm footing. Be sure no one is below when using the tool in high locations.

- The proper fastening torque may differ depending upon the kind or size of the bolt. Check the torque with a torque wrench.

- Use auxiliary handle(s), if supplied with the tool. Loss of control can cause personal injury.

- Hold power tool by insulated gripping surfaces, when performing an operation where the cutting accessory may contact hidden wiring. Cutting accessory contacting a “live” wire may make exposed metal parts of the power tool “live” and could give the operator an electric shock.

- Keep hands away from rotating parts.

- Do not touch the drill bit or the workpiece immediately after operation; they may be extremely hot and could burn your skin.

- Some material contains chemicals that may be toxic. Take caution to prevent dust inhalation and skin contact. Follow material supplier safety data.

SAVE THESE INSTRUCTIONS

.

Important safety instructions for battery cartridge

- Before using the battery cartridge, read all instructions and cautionary markings on (1) battery charger, (2) battery, and (3) product using the battery.

- Do not disassemble the battery cartridge.

- If the operating time has become excessively shorter, stop operating immediately. It may result in a risk of overheating, possible burns and even an explosion.

- If electrolyte gets into your eyes, rinse them out with clear water and seek medical attention right away. It may result in loss of your eyesight.

- Do not short the battery cartridge: (1) Do not touch the terminals with any conductive material. (2) Avoid storing battery cartridge in a container with other metal objects such as nails, coins, etc. (3) Do not expose the battery cartridge to water or rain. A battery short can cause a large current flow, overheating, possible burns and even a breakdown.

- Do not store the tool and battery cartridge in locations where the temperature may reach or exceed 50 °C (122 °F).

- Do not incinerate the battery cartridge even if it is severely damaged or is completely worn out. The battery cartridge can explode in a fire.

- Be careful not to drop or strike the battery.

- Do not use a damaged battery.

- The contained lithium-ion batteries are subject to the Dangerous Goods Legislation requirements. For commercial transports e.g. by third parties or forwarding agents, the special requirements on packaging and labeling must be observed. For the preparation of the item being shipped, consulting an expert for hazardous material is required. Please also observe possibly more detailed national regulations. Tape or mask off open contacts and pack up the battery in such a manner that it cannot move around in the packaging.

- Follow your local regulations relating to the disposal of batteries.

SAVE THESE INSTRUCTIONS.

- Charge the battery cartridge before completely discharged. Always stop tool operation and charge the battery cartridge when you notice less tool power.

- Never recharge a fully charged battery cartridge. Overcharging shortens the battery service life.

- Charge the battery cartridge with room temperature at 10 °C – 40 °C (50 °F – 104 °F). Let a hot battery cartridge cool down before charging it.

- Charge the battery cartridge if you do not use it for a long period (more than six months).

FUNCTIONAL DESCRIPTION CAUTION

Installing or removing the battery cartridge

► Fig.1: 1. Red indicator 2. Button 3. Battery cartridge To remove the battery cartridge, slide it from the tool while sliding the button on the front of the cartridge. To install the battery cartridge, align the tongue on the battery cartridge with the groove in the housing and slip it into place. Insert it all the way until it locks in place with a little click. If you can see the red indicator on the upper side of the button, it is not locked completely.

Battery protection system

Lithium-ion battery with star marking

► Fig.2: 1. Star marking

Lithium-ion batteries with a star marking are equipped with a protection system. This system automatically cuts off power to the tool to extend battery life.

The tool will automatically stop during operation if the tool and/or battery are placed under one of the following conditions:

Overloaded:

The tool is operated in a manner that causes it to draw an abnormally high current.

In this situation, turn the tool off and stop the application that caused the tool to become overloaded. Then turn the tool on to restart.

If the tool does not start, the battery is overheated. In this situation, let the battery cool before turning the tool on again.

Low battery voltage:

The remaining battery capacity is too low and the tool will not operate. In this situation, remove and recharge the battery.

Indicating the remaining battery capacity

Only for battery cartridges with “B” at the end of the model number

► Fig.3: 1. Indicator lamps 2. Check button

Press the check button on the battery cartridge to indicate the remaining battery capacity. The indicator lamps light up for few seconds.

| Indicator lamps | Remaining capacity | ||

| |

|

| |

| 75% to 100% | |||

| 50% to 75% | |||

| 25% to 50% | |||

| 0% to 25% | |||

| Charge the battery. | |||

| The battery may have malfunctioned. | |||

NOTE: Depending on the conditions of use and the ambient temperature, the indication may differ slightly from the actual capacity.

► Fig.4: 1. Switch trigger

To start the tool, simply pull the switch trigger. Tool speed is increased by increasing pressure on the switch trigger. Release the switch trigger to stop.

NOTE: The tool automatically stops if you keep pulling the switch trigger for about 6 minutes.

Lighting up the front lamp

► Fig.5: 1. Lamp

► Fig.6: 1. Button

To turn on the lamp status, press the button

With the lamp status ON, pull the switch trigger to turn on the lamp. To turn it off, release it. The lamp goes out approximately 10 seconds after releasing the switch trigger.

With the lamp status OFF, the lamp does not turn on even if pulling the trigger.

NOTE: To confirm the lamp status, pull the trigger.

When the lamp lights up by pulling the switch trigger, the lamp status is ON. When the lamp does not come on, the lamp status is OFF.

NOTE: When the tool is overheated, the light flashes for one minute, and then the LED display goes off. In this case, cool down the tool before operating again.

NOTE: Use a dry cloth to wipe the dirt off the lens of the lamp. Be careful not to scratch the lens of the lamp, or it may lower the illumination.

NOTE: While pulling the switch trigger, the lamp status cannot be changed.

NOTE: For approximately 10 seconds after releasing the switch trigger, the lamp status can be changed.

Reversing switch action

► Fig.7: 1. Reversing switch lever

This tool has a reversing switch to change the direction of rotation. Depress the reversing switch lever from the A-side for clockwise rotation or from the B side for counterclockwise rotation. When the reversing switch lever is in the neutral position, the switch trigger cannot be pulled.

Changing the impact force

► Fig.8: 1. Changed in three steps 2. Hard 3. Medium

4. Soft 5. Button

You can change the impact in three steps: hard, medium and soft mode.

This allows a tightening suitable to the work.

Every time the button

For approximately one minute after releasing the switch trigger, the impact force can be changed.

Specifications of each impact force grade

| Impact force grade displayed on panel | Maximum blows |

Application | ||

| DTW1001 | DTW1002 | DTW800 | ||

| 2,200 min-1 (/min) | Tightening when force and speed are desired. | |||

| 2,000 min-1 (/min) | Tightening when you need good controlled power. | |||

| 1,800 min-1 (/min) | Tightening when you need fine adjustment with small diameter bolt. | |||

Impact force/bolt size corresponding chart (reference)

| Impact force grade displayed on

panel |

DTW1001 | DTW1002 | DTW800 | |||

| Standard bolt | High tensile bolt | Standard bolt | High tensile bolt | Standard bolt | High tensile bolt | |

|

M20 – M30 (3/4″ – 1-1/4″) |

M16 – M24 (5/8″ – 1″) |

M20 – M30 (3/4″ – 1-1/4″) |

M16 – M24 (5/8″ – 1″) |

M20 – M24 (3/4″ – 1″) |

M16 – M22 (5/8″ – 7/8″) |

| M16 – M24 (5/8″ – 1″) |

M12 – M20 (1/2″ – 3/4″) |

M16 – M24 (5/8″ – 1″) |

M12 – M20 (1/2″ – 3/4″) |

M14 – M20 (9/16″ – 3/4″) |

M10 – M16 (3/8″ – 5/8″) | |

| M12 – M20 (1/2″ – 3/4″) |

M10 – M16 (3/8″ – 5/8″) |

M12 – M20 (1/2″ – 3/4″) |

M10 – M16 (3/8″ – 5/8″) |

M12 – M16 (1/2″ – 5/8″) |

M10 – M12 (3/8″ – 1/2″) | |

ASSEMBLY

CAUTION: Always be sure that the tool is switched off and the battery cartridge is removed before carrying out any work on the tool.

Selecting the correct impact socket Always use the correct size impact socket for bolts and nuts. An incorrect size impact socket will result in inaccurate and inconsistent fastening torque and/or damage to the bolt or nut.

Installing or removing impact socket

Only for Model DTW1001,DTW1002 (optional accessory)

CAUTION: Make sure that the impact socket and the mounting portion are not damaged before installing the impact socket.

For impact socket without O-ring and pin

► Fig.9: 1. Impact socket 2. Square drive

Align the square of the impact socket with the square drive and push the impact socket onto the square drive until it locks into place. Tap it lightly if required.

To remove the impact socket, simply pull it off.

For impact socket with O-ring and pin

Only for Model DTW1001

► Fig.10:

- Impact socket

- O-ring

- Pin

Move the O-ring out of the groove in the impact socket and remove the pin from the impact socket. Fit the impact socket onto the square drive so that the hole in the impact socket is aligned with the hole in the square drive. Insert the pin through the hole in the impact socket and square drive. Then return the O-ring to the original position in the impact socket groove to retain the pin. To remove the impact socket, follow the installation procedures in reverse.

Installing or removing drill bit/ socket adapter

Only for Model DTW800 (optional accessory)

► Fig.11

A=11.2 mm

Use only the drill bit/socket adapter shown in the figure.

Do not use any other drill bit/socket adapter.

► Fig.12: 1. Drill bit 2. Sleeve

To install the drill bit, pull the sleeve in the direction of the arrow and insert the drill bit into the sleeve as far as it will go.

Then release the sleeve to secure the drill bit.

To remove the drill bit, pull the sleeve in the direction of the arrow and pull the drill bit out.

NOTE: If the drill bit is not inserted deep enough into the sleeve, the sleeve will not return to its original position and the drill bit will not be secured. In this case, try re-inserting the drill bit according to the instructions above.

NOTE: After inserting the drill bit, make sure that it is firmly secured. If it comes out, do not use it.

Ring

Only for Model DTW800

► Fig.13: 1. Bracket 2. Ring 3. Screws

The ring is convenient for hanging the tool with hoist.

First, place the rope through the ring. Then hang the tool up to the air with a hoist.

CAUTION: Before using the ring, always make sure that the bracket and ring are secured and not damaged.

Installing hook

► Fig.14: 1. Groove 2. Hook 3. Screw

The hook is convenient for temporarily hanging the tool.

This can be installed on either side of the tool. To install the hook, insert it into a groove in the tool housing on either side and then secure it with two screws. To

remove, loosen the screws and then take it out.

OPERATION

► Fig.15

Hold the tool firmly and place the impact socket over the bolt or nut. Turn the tool on and fasten for the proper fastening time.

The proper fastening torque may differ depending upon the kind or size of the bolt, the material of the workpiece to be fastened, etc. The relation between fastening torque and fastening time is shown in the figures.

Model DTW800

Proper fastening torque for a standard bolt

Proper fastening torque for high tensile bolt

NOTE: Hold the tool pointed straight at the bolt or nut.

NOTE: Excessive fastening torque may damage the bolt/nut or impact socket. Before starting your job, always perform a test operation to determine the

proper fastening time for your bolt or nut.

NOTE: If the tool is operated continuously until the battery cartridge has discharged, allow the tool to rest for 15 minutes before proceeding with a fresh battery cartridge.

The fastening torque is affected by a wide variety of factors including the following. After fastening, always check the torque with a torque wrench.

- When the battery cartridge is discharged almost completely, the voltage will drop and the fastening torque will be reduced.

- Impact socket

• Failure to use the correct size impact socket will cause a reduction in the fastening torque.

• A worn impact socket (wear on the hex end or square end) will cause a reduction in the fastening torque. - Bolt

• Even though the torque coefficient and the class of bolt are the same, the proper fastening torque will differ according to the diameter of the bolt.

• Even though the diameters of bolts are the same, the proper fastening torque will differ according to the torque coefficient, the class of bolt, and the bolt length. - The use of the universal joint or the extension bar somewhat reduces the fastening force of the impact wrench. Compensate by fastening for a longer period of time.

- The manner of holding the tool or the material of the driving position to be fastened will affect the torque.

- Operating the tool at low speed will cause a reduction in the fastening torque.

MAINTENANCE

CAUTION: Always be sure that the tool is switched off and the battery cartridge is removed before attempting to perform inspection or maintenance.

NOTICE: Never use gasoline, benzene, thinner, alcohol or the like. Discoloration, deformation or cracks may result.

To maintain product SAFETY and RELIABILITY, repairs, any other maintenance or adjustment should be performed by Makita Authorized or Factory Service Centers, always using Makita replacement parts.

OPTIONAL ACCESSORIES

- Impact socket

- Drill bits (only for Model DTW800)

- Extension bar

- Universal joint

- Makita genuine battery and charger

NOTE: Some items in the list may be included in the tool package as standard accessories. They may differ from country to country.

Makita Jan-Baptist Vinkstraat 2, 3070, Belgium

Makita Corporation Anjo, Aichi, Japan

www.makita.com

885444A976

EN, PL, HU, SK,

CS, UK, RO, DE

20151218