Bosch 300 HV GRL Professional Rotation Laser Instruction Manual

300 HV GRL Professional Rotation Laser

GRL Professional

250 HV | 300 HV | 300 HVG

Safety Notes

Rotational Laser Level

Working safely with the measuring tool is possible only when the operating and safety information are read completely and the instructions contained therein are strictly followed. Never make warning labels on the measuring tool unrecognizable.

SAVE THESE INSTRUCTIONS

- Caution – The use of other operating or adjusting equipment or the application of other processing methods than those mentioned here, can lead to dangerous radiation exposure.

- Do not use the laser viewing glasses as safety

goggles. The laser viewing glasses are used for improved visualization of the laser beam, but they do not protect against laser radiation. - Do not use the laser viewing glasses as sun glasses or in traffic. The laser viewing glasses do not afford complete UV protection and reduce colour perception.

- Have the measuring tool repaired only through qualified specialists using original spare parts. This ensures that the safety of the measuring tool is maintained.

- Do not operate the measuring tool in explosive environments, such as in the presence of flammable liquids, gases or dusts. Sparks can be created in the measuring tool which may ignite the dust or fumes.

- Do not open the battery pack. Danger of short-circuiting.

Protect the battery pack against heat, e.g., against continuous intense sunlight, fire, water, and moisture. Danger of explosion. - Keep the battery pack not being used away from paper clips, coins, keys, nails, screws or other small metal objects that can make a connection from one terminal to another.

Shorting the battery terminals together may cause burns or a fire. - Under abusive conditions, liquid may be ejected from the battery; avoid contact. If contact accidentally occurs, flush with water.

If liquid contacts eyes, additionally seek medical help. Liquid ejected from the battery may cause irritations or burns. - Charge the battery pack only with the battery charger specified in these operating instructions.

A charger that is suitable for one type of battery pack may create a risk of fire when used with another battery pack. - Use only original Bosch battery packs with the voltage listed on the nameplate of your measuring tool. When using other battery packs, e.g. imitations, reconditioned battery packs or other brands, there is danger of injury as well as property damage through exploding battery packs.

GRL 250 HV

- The measuring tool is provided with a warning label in English (marked with number 20 in the representation of the measuring tool on the graphics page).

- Do not direct the laser beam at persons or animals and do not stare into the laser beam yourself. This measuring tool produces laser class 2 laser radiation according to IEC 60825-1. This can lead to persons being blinded.

- Do not allow children to use the laser measuring tool without supervision. They could unintentionally blind other persons or themselves.

GRL 300 HV/GRL 300 HVG

- The measuring tool is provided with two warning labels in English (marked with number 20 and 21 in the representation of the measuring tool on the graphics page).

- Do not direct the laser beam at persons or animals and do not look into the laser beam yourself. This measuring tool generates laser radiation from class 3R according to IEC 60825-1. Looking directly into the laser beam – even from a greater distance cause damages to the eyes.

- Avoid reflection of the laser beam on smooth surfaces such as windows or mirrors.

A reflected laser beam can also cause damage to the eye. - The measuring tool should be operated only by persons that are familiar with the handling of laser devices. According to EN 60825-1, this includes, among other things, the knowledge about the bioligical effects of the laser to the eyes and the skin as well as the correct usage of laser protection devices in order to avoid dangers.

- Always set up the measuring tool in such a manner that the laser beams run far above or below eye level. This ensures that damage to the eyes will not occur.

- Mark the area in which the measuring tool is being used with suitable laser warning labels. This prevents persons not involved from accessing the danger area.

- Do not store the measuring tool at locations, to which unauthorised persons have access. Persons not familiar with the operation of the measuring tool can cause harm to themselves and to others.

- When using a class 3R measuring tool, observe possible national regulations. Non-observance of these regulations can lead to injury.

- Make sure that the area of laser radiation is monitored or shielded. The limitation of laser radiation to controlled areas prevents eye damage to persons not involved.

Battery Charger

Read all safety warnings and all instructions.

Failure to follow the warnings and instructions may result in electric shock, fire and/or serious injury.

Keep the battery charger away from rain or moisture. Penetration of water in the battery charger increases the risk of an electric shock.

- Do not charge other batteries with the battery charger. The battery charger is only suitable for charging the Bosch battery/battery pack inserted in the rotational laser level.

Danger of fire and explosion when charging other batteries/battery packs. - Keep the battery charger clean. Contamination can lead to danger of an electric shock.

- Before each use, check the battery charger, cable and plug. If damage is detected, do not use the battery charger. Never open the battery charger yourself. Have repairs performed only by a qualified technician and only using original spare parts. Damaged battery chargers, cables and plugs increase the risk of an electric shock.

- Do not operate the battery charger on easily inflammable surfaces (e. g., paper, textiles, etc.) or surroundings. The heating of the battery charger during the charging process can pose a fire hazard.

- Under abusive conditions, liquid may be ejected from the battery; avoid contact. If contact accidentally occurs, flush with water.

If liquid contacts eyes, additionally seek medical help. Liquid ejected from the battery may cause irritations or burns. - Children should be supervised to ensure that they do not play with the battery charger.

- Children or persons with mental or physical limitations may only use the charger under supervision or after having been instructed.

A thorough introduction reduces operating errors and injuries. - Products sold in GB only: Your product is fitted with an BS 1363/A approved electric plug with internal fuse (ASTA approved to BS 1362).

If the plug is not suitable for your socket outlets, it should be cut off and an appropriate plug fitted in its place by an authorised customer service agent. The replacement plug should have the same fuse rating as the original plug.

The severed plug must be disposed of to avoid a possible shock hazard and should never be inserted into a mains socket elsewhere.

Functional Description

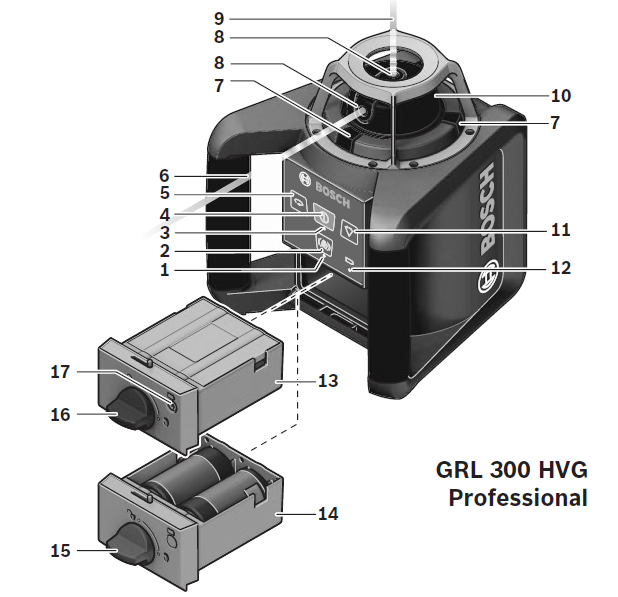

While reading the operating instructions, unfold the graphics page with the illustration of the rotational laser level and battery charger, and leave it open.

Intended Use

Rotational Laser Level

The measuring tool is intended for determining and checking precise horizontal partitions, vertical lines, building lines and plumb points.

The measuring tool is suitable for indoor and outdoor use.

Technical Data

Assembly

Power Supply of the Rotational Laser Level

Operation with Batteries/Rechargeable Batteries

Using alkali-manganese or rechargeable batter-ies is recommended for operation of the meas-using tool.

To open the battery compartment 14, turn the locking knob 15 to position

When inserting batteries, pay attention to the correct polarity according to the representation on the inside of the battery compartment.

Always replace all batteries at the same time. Only use batteries from one brand and with the identical capacity.

Shut the battery compartment 14 and turn the locking knob 15 to the

In case the batteries have been inserted incorrectly, the measuring tool cannot be switched on. Insert the batteries with correct polarity.

Remove the batteries from the measuring tool when not using it for extended periods. When storing for extended periods, the batteries can corrode and discharge them-selves.

Operation with Battery Pack

Charge the battery pack 13 before using for the first time. The battery pack can only be charged with the battery charger 22 intended for it.

- Observe the mains voltage! The voltage of the power supply must correspond with the data given on the nameplate of the battery charger. Battery chargers marked with 230 V can also be operated with 220 V.

Insert the appropriate mains plug 23 for your mains supply into the battery charger 22 and al-low it to engage.

Insert the charge plug 24 of the battery charger into the socket connector 17 of the battery pack. Connect the battery charger to the mains supply. Charging the empty battery pack takes approx. 14 h. The battery charger and the battery pack are protected against overcharging.

A battery that is new or has not been used for a longer period does not develop its full capacity until after approx. 5 charging/discharging cycles.

Do not charge the battery pack 13 each time after using, otherwise its capacity will be reduced. Charge the battery pack only when the charge-control indicator 12 flashes or lights up continuously.

A considerably reduced operating period after charging indicates that the battery pack is used up and must be replaced.

If the battery pack is empty, the measuring tool can also be operated off of the battery charger 22 when connected to a power supply. Switch the measuring tool off, charge the battery pack for approx. 10 min and then switch the measuring tool on again with the battery charger con-nected.

To change the battery pack 13, turn the locking knob 16 to

Insert a new battery pack and turn the locking knob 16 to the

- Remove the battery pack from the measuring tool when not using it for longer periods. When storing for longer periods, the re-chargeable batteries can corrode and discharge themselves.

Charge-control Indicator

When the charge-control indicator 12 flashes red for the first time, the measuring tool can still be operated for approx. 2 h.

When the charge-control indicator 12 lights up red continuously, measurements are no longer possible. The measuring tool switches off automatically after 1 minute.

Operation

Starting Operation of the Rotational Laser Level

- Protect the measuring tool against moisture and direct sun light.

- Do not subject the measuring tool to extreme temperatures or variations in temperature. As an example, do not leave it in vehicles for longer periods. In case of large variations in temperature, allow the measuring tool to adjust to the ambient temperature before putting it into operation. In case of extreme temperatures or variations in temperature, the accuracy of the measuring tool can be impaired.

- Avoid heavy impact to or dropping down of the measuring tool. After severe exterior effects to the measuring tool, it is recommended to carry out an accuracy check (see “Levelling Accuracy of the Rotational Laser Level”, page 30) each time before continuing to work.

Setting Up the Measuring Tool

Set up the measuring tool on a sturdy surface in the horizontal or vertical position; mount it on a tripod 26 or to the wall mount with alignment unit 30.

Due to the high levelling accuracy, the measuring tool reacts sensitively to ground vibrations and position changes. Therefore, pay attention that the position of the measuring tool is stable in order to avoid operational interruptions due to re-levelling.

Switching On and Off

- Do not direct the laser beam at persons or animals (especially not at their eye level), and do not stare into the laser beam your-self (not even from a distance). Immediately after switching on, the measuring tool sends out the vertical plumb beam 9 and the variable laser beam 6.

For switching on the measuring tool, press the On/Off button 4. The indicators 1, 3 and 12 light up briefly. The measuring tool immediately starts the automatic levelling. During the level-ling, the levelling indicator 3 lights up green and the laser flashes in point operation.

The measuring tool is levelled in as soon as levelling indicator 3 lights up green continuously and the laser beam is steady. After the levelling is completed, the measuring tool automatically starts in rotational operation.

With the operating mode buttons 5 and 11, the operating modes can already be specified during levelling in (see “Operating Modes of the Rotational Laser Level”, page 29). In this case, the measuring tool starts in the set operating mode upon completion of levelling in.

To switch off the measuring tool, press the On/Off button 4 again.

- Do not leave the switched on measuring tool unattended and switch the measuring tool off after use. Other persons could be blinded by the laser beam.

To save the batteries, the measuring tool is automatically switched off when not within the self-levelling range for more than 2 h or when the shock warning is actuated for more than 2 h (see “Automatic Levelling of the Rotational Laser Level”, page 29). Reposition the measuring tool and switch it on again.

Operating Modes of the Rotational Laser Level

Overview

All three operating modes are possible with the measuring tool in horizontal and vertical position.

Each time after switching on, the measuring tool is in rotational operation mode with average rotational speed.

To switch from line operation to rotational operation, press the rotational operation button 5. Rotational operation starts with average rotational speed.

To change the rotational speed, press the rotational operation button 5 again until the re-quested speed is reached.

When working with the laser receiver, the highest rotational speed should be set. When working without laser receiver, reduce the rotational speed for improved visibility of the laser beam and use the laser viewing glasses 29.

Line Operation, Point Operation (10°/25°/50°, 0°)

To switch to line or point operation, press the line operation button 11. The measuring tool switches to line operation with the smallest ap-erture angle.

To change the aperture angle, press the line op-eration button 11. The aperture angle is in-creased in two steps; at the same time, the ro-tational speed is increased with each step. When pressing the line operation button 11 a third time, the measuring tool switches to point operation after brief post-pulsation. Pressing button 11 again takes you back to line operation with the smallest aperture angle.

Note: Due to inertia, it is possible for the laser to slightly move beyond the end point of the laser line.

To position the laser line or the laser point with-in the rotational plane, manually turn the rotation head 10 to the requested position or use the remote control 25.

Turning the Rotational Plane when in the Vertical Position

When the measuring tool is in the vertical position, it is possible to rotate the laser point, laser line or rotational plane around the vertical axis with help of the remote control 25. For this, observe the operating instructions of the remote control.

Automatic Levelling of the Rotational Laser Level

Overview

After switching on, the measuring tool automatically detects the horizontal or vertical position. To change between the horizontal and vertical position, switch the measuring tool off, reposition it and switch on again.

After switching on, the measuring tool checks the horizontal and vertical position and automatically levels out any unevenness within the self-levelling range of approx. 8 % (5°).

When the measuring tool is inclined by more than 8 % after switching on or after a position change, levelling in is no longer possible. In this case, the rotor is stopped, the laser flashes and levelling indicator 3 continuously lights up red. Reposition the measuring tool and wait for it to re-level. Without repositioning, the laser is auto-matically switched off after 2 minutes and the measuring tool after 2 hours.

When the measuring tool is levelled in, it contin-uously checks the horizontal and vertical posi-tion. Automatic re-levelling takes place after po-sition changes. To avoid faulty measurements, the rotor stops during the levelling process, the laser flashes and the levelling indicator 3 flashes green.

Shock-warning Function

The measuring tool has a shock-warning func-tion; after position changes or shock to the measuring tool, or in case of ground vibrations, it keeps the measuring tool from levelling in at changed heights, and thus prevents vertical er-rors.

To switch on the shock-warning function, press the shock-warning button 2. The shock-warning indicator 1 continuously lights up green, and the shock-warning function is activated after 30 sec-onds.

When the levelling-accuracy range is exceeded after a position change of the measuring tool or when heavy ground vibrations are detected, the shock-warning function is actuated: The rota-tion is stopped, the laser flashes, the levelling indicator 3 goes out and the shock-warning indi-cator 1 flashes red. The current operating mode is stored.

After the shock-warning function has actuated, press the shock-warning button 2. The shock-warning function is restarted and the measuring tool starts the levelling. As soon as the measur-ing tool is levelled in (levelling indicator 3 con-tinuously lights up green), it starts in the stored operating mode. Now, check the height of the la-ser beam with a reference point and correct the height, if required.

When the function is not restarted by pressing button 2 after the shock-warning function has actuated, the laser is automatically switched off after 2 minutes and the measuring tool after 2hours.

To switch off the shock-warning function, press shock-warning button 2 once, or, when the shock warning is actuated (shock-warning indicator 1 flashing red) press it twice. When the shock-warning function is shut off, the shock-warning indicator 1 goes out.

Levelling Accuracy of the Rotational Laser Level

Influences on Accuracy

The ambient temperature has the greatest influ-ence. Especially temperature differences occur-ring from the ground upward can divert the laser beam.

The deviations play a role in excess of approx. 20 m measuring distance and can easily reach two to four times the deviation at 100 m.

Because the largest difference in temperature layers is close to the ground, the measuring tool should always be mounted on a tripod when measuring distances exceeding 20 m. If possi-ble, also set up the measuring tool in the centre of the work area.

Accuracy Check of the Measuring Tool

Apart from exterior influences, device-specific influences (such as heavy impact or falling down) can lead to deviations. Therefore, check the accuracy of the measuring tool each time be-fore starting your work.

For the accuracy check, an unobstructed measuring distance of 20 m on firm ground between two walls A and B is required. With the measuring tool in the horizontal position, a transit measurement is to be carried out across both axes X and Y (both positive and negative) (altogether 4 complete measurements).

– Mount the measuring tool in the horizontal position onto a tripod 26 (accessory) or place it on a firm and level surface near wall A. Switch the measuring tool on.

Working with the Laser Receiver (Accessory)

Under unfavourable light conditions (bright environment, direct sunlight) and for larger distances, use the laser receiver for improved finding of the laser beam 28.

When working with the laser receiver, select rotational operation with the highest rotational speed.

Before working with the laser receiver, read and observe the laser receiver operating instructions.

Working with the Remote Control (Accessory)

While pressing the operator buttons, the measuring tool can be brought out of alignment so that the rotation is briefly stopped. This effect is avoided when using the remote control 25.

Reception lenses 7 for the remote control are located on three sides of the measuring tool, among other locations above the control panel on the front side.

Working with the Tripod (Accessory)

The measuring tool is equipped with a 5/8″ tri-pod mount for horizontal operation on a tripod. Place the measuring tool via the tripod mount 18 onto the 5/8″ male thread of the tripod and screw the locking screw of the tripod tight.

On a tripod 26 with a measuring scale on the elevator column, the height difference can be adjusted directly.

Working with Wall Mount/Alignment Unit (Accessory) (see figure A)

You can also mount the measuring tool to the wall mount with alignment unit 30. For this, screw the 5/8″ screw 33 of the wall mount into the tripod mount 18 of the measuring tool.

Mounting to a wall: Mounting to a wall is recommended, e.g., for work above the elevation height of tripods or for work on unstable surfaces and without tripod. For this, fasten the wall mount 30, with the measuring tool mounted, as vertical as possible to a wall.

For mounting to the wall, you can either fasten the wall mount 30 with fastening screw 31 to a lath (width maximal 8 mm) or hang it up with two hooks.

Mounting on a tripod: The wall mount 30 can also be screwed onto a tripod with the tripod mount on the back side. This method of fastening is especially recommended for work where the rotational plane is to be aligned with a reference line.

With the alignment unit, the mounted measuring tool can be moved vertically (when mounted to the wall) or horizontally (when mounted to a tri-pod) within a range of approx. 16 cm. For this, loosen screw 32 on the alignment unit, move the measuring tool to the desired position, and retighten screw 32 again.

Working with the Ceiling Measurement Plate (see figure A)

As an example, the ceiling measurement plate 35 can be used for easy height adjustment of drop ceilings. Fasten the ceiling measurement plate with the magnetic holder, e.g., to a beam.

The reflecting half of the ceiling measurement plate improves the visibility of the laser beam in unfavourable conditions; the laser beam can al-so be seen from the rear side through the trans-parent half.

Working with the Measuring Plate (Accessory)

With the measuring plate 34, it is possible to project the laser mark onto the floor or the laser height onto a wall.

With the zero field and the scale, the offset or drop to the required height can be measured and projected at another location. This eliminates the necessity of precisely adjusting the measuring tool to the height to be projected.

The measuring plate 34 has a reflective coating that enhances the visibility of the laser beam at greater distances or in intense sunlight. The brightness intensification can be seen only when viewing, parallel to the laser beam, onto the measuring plate.

Working with the Measuring Rod (Accessory) (see figure H)

For checking irregularities or projecting gradients, it is recommended to use the measuring rod 27 together with the laser receiver.

A relative millimeter scale (±50 cm) is marked on the top of the measuring rod 27. Its zero height can be preset at the bottom of the elevator column. This allows for direct reading of deviations from the specified height.

Work Examples

Projecting/Checking Heights (see figure B)

Position the measuring tool in the horizontal position onto a firm support or mount it onto a tri-pod 26 (accessory).

Working with tripod: Align the laser beam to the requested height. Project or check the height at the target location.

Working without tripod: Determine the height difference between the laser beam and the height at the reference point with help of the measurement plate 34. Project or check the measured height difference at the target location.

Parallel Alignment of a Plumb Beam/Project-ing Right Angles (see figure C)

When right angles are to be projected or when partitions are to be aligned, the plumb beam 9 must be aligned parallel, meaning at the same distance to a reference line (e.g. a wall).

For this, set up the measuring tool in the vertical position and position it in such a manner that the plumb beam runs approximately parallel to the reference line.

For exact positioning, measure the clearance between plumb beam and reference line direct-ly on the measuring tool with help of the meas-urment plate 34. Measure the clearance be-tween plumb beam and reference line again as far away as possible from the measuring tool. Align the plumb beam in such a manner that it has the same clearance to the reference line as when measured directly at the measuring tool.

The right angle to the plumb beam 9 is indicated by the variable laser beam 6.

Indicating a Plumb Line/Vertical Plane (see figure D)

To indicate a plumb line or a vertical plane, set up the measuring tool in the vertical position. When the vertical plane is supposed to run at a right angle to a reference line (e.g. a wall), then align the plumb beam 9 with this reference line.

The plumb line is indicated by the variable laser beam 6.

Working without Laser Receiver (see figure E)

Under favourable light conditions (dark environment) and for short distances, it is possible to work without the laser receiver. For better visibility of the laser beam, either select line operation, or select point operation and manually rotate the rotation head 10 to the target location.

Working with the Laser Receiver (see figure F)

Under unfavourable light conditions (bright environment, direct sunlight) and for larger distances, use the laser receiver for improved finding of the laser beam. When working with the laser receiver, select rotational operation with the highest rotational speed.

Measuring Over Long Distances (see figure G)

When measuring over long distances, the laser receiver must be used to find the laser beam. In order to reduce interferences, the measuring tool should always be set up in the centre of the work surface and on a tripod.

Working Outdoors (see figure H)

The laser receiver should always be used when working outdoors.

When working on unstable ground, mount the measuring tool onto the tripod 26. Activate the shock-warning function in order to avoid faulty measurements in case of ground vibrations or shock to the measuring tool.

Overview of Indications

Maintenance and Service

Maintenance and Cleaning

Keep the rotational laser level and battery charg-er clean at all times.

Do not immerse the rotational laser level and battery charger into water or other fluids.

Wipe off debris using a moist and soft cloth. Do not use any cleaning agents or solvents.

Particularly clean the surfaces at the outlet opening of the rotational laser level regularly and pay attention for any lint.

If the rotational laser level or battery charger should fail despite the care taken in manufacture and testing, repair should be carried out by an authorised customer services agent for Bosch power tools. Do not open the rotational laser level and the battery charger yourself.

In all correspondence and spare parts orders, please always include the 10-digit article number given on the type plate of the rotational laser level and battery charger.

After-sales Service and Customer Assistance

Our after-sales service responds to your questions concerning maintenance and repair of your product as well as spare parts. Exploded views and information on spare parts can also be found under:

www.bosch-pt.com

Our customer service representatives can answer your questions concerning possible applications and adjustment of products and accessories.

Great Britain

Robert Bosch Ltd. (B.S.C.)

P.O. Box 98

Broadwater Park

North Orbital Road

Denham

Uxbridge

UB 9 5HJ

Tel. Service: +44 (0844) 736 0109

Fax: +44 (0844) 736 0146

E-Mail:

Ireland

Origo Ltd.

Unit 23 Magna Drive

Magna Business Park

City West

Dublin 24

Tel. Service: +353 (01) 4 66 67 00

Fax: +353 (01) 4 66 68 88

Australia, New Zealand and Pacific Islands

Robert Bosch Australia Pty. Ltd.

Power Tools

Locked Bag 66

Clayton South VIC 3169

Customer Contact Center

Inside Australia:

Phone: +61 (01300) 307 044

Fax: +61 (01300) 307 045

Inside New Zealand:

Phone: +64 (0800) 543 353

Fax: +64 (0800) 428 570

Outside AU and NZ:

Phone: +61 (03) 9541 5555

www.bosch.com.au

Republic of South Africa

Customer service

Hotline: +27 (011) 6 51 96 00

Gauteng – BSC Service Centre

35 Roper Street, New Centre Johannesburg

Tel.: +27 (011) 4 93 93 75

Fax: +27 (011) 4 93 01 26

E-Mail:

KZN – BSC Service Centre

Unit E, Almar Centre

143 Crompton Street

Pinetown

Tel.: +27 (031) 7 01 21 20

Fax: +27 (031) 7 01 24 46

E-Mail:

Western Cape – BSC Service Centre Democracy Way, Prosperity Park Milnerton

Tel.: +27 (021) 5 51 25 77

Fax: +27 (021) 5 51 32 23

E-Mail:

Bosch Headquarters

Midrand, Gauteng

Tel.: +27 (011) 6 51 96 00

Fax: +27 (011) 6 51 98 80

E-Mail:

People’s Republic of China

Website: www.bosch-pt.com.cn

China Mainland

Bosch Power Tools (China) Co., Ltd.

567, Bin Kang Road

Bin Jiang District 310052

Hangzhou, P.R.China

Service Hotline: 400 826 8484

Fax: +86 (571) 87 77 45 02

E-Mail:

HK and Macau Special Administrative Regions Robert Bosch Hong Kong Co. Ltd.

21st Floor, 625 King’s Road

North Point, Hong Kong

Customer Service Hotline: +852 (21) 02 02 35 Fax: +852 (25) 90 97 62

E-Mail:

www.bosch-pt.com.cn

Indonesia

PT. Multi Tehaka

Kawasan Industri Pulogadung

Jalan Rawa Gelam III No. 2

Jakarta 13930

Indonesia

Tel.: +62 (21) 46 83 25 22

Fax: +62 (21) 46 82 86 45/68 23

E-Mail:

www.multitehaka.co.id

Philippines

Robert Bosch, Inc.

28th Floor Fort Legend Towers,

3rd Avenue corner 31st Street,

Fort Bonifacio Global City,

1634 Taguig City, Philippines

Tel.: +63 (2) 870 3871

Fax: +63 (2) 870 3870

www.bosch-pt.com.ph

Bosch Service Center:

9725-27 Kamagong Street

San Antonio Village

Makati City, Philippines

Tel.: +63 (2) 899 9091

Fax: +63 (2) 897 6432

Malaysia

Robert Bosch (S.E.A.) Pte. Ltd.

No. 8A, Jalan 13/6

G.P.O. Box 10818

46200 Petaling Jaya

Selangor, Malaysia

Tel.: +60 (3) 7966 3194

Fax: +60 (3) 7958 3838

Toll-Free: 1800 880 188

www.bosch-pt.com.my

Thailand

Robert Bosch Ltd.

Liberty Square Building

No. 287, 11 Floor

Silom Road, Bangrak

Bangkok 10500

Tel.: +66 (2) 6 31 18 79 – 18 88 (10 lines) Fax: +66 (2) 2 38 47 83

Robert Bosch Ltd., P. O. Box 2054 Bangkok 10501, Thailand

Bosch Service – Training Centre

2869-2869/1 Soi Ban Kluay

Rama IV Road (near old Paknam Railway) Prakanong District

10110 Bangkok

Thailand

Tel.: +66 (2) 6 71 78 00 – 4

Fax: +66 (2) 2 49 42 96

Fax: +66 (2) 2 49 52 99

Singapore

Robert Bosch (SEA) Pte. Ltd. 11 Bishan Street 21

Singapore 573943

Tel.: +65 6571 2772

Fax: +65 6350 5315 Toll-Free: 1800 333 8333 www.bosch-pt.com.sg

Vietnam

Robert Bosch Vietnam Co. Ltd 10/F, 194 Golden Building

473 Dien Bien Phu Street Ward 25, Binh Thanh District 84 Ho Chi Minh City

Vietnam

Tel.: +84 (8) 6258 3690 ext. 413 Fax: +84 (8) 6258 3692

www.bosch-pt.com

Disposal

Do not dispose of the rotational laser level, bat-tery charger and battery packs/batteries into household waste!

Only for EC countries:

According to the European Guide-line 2002/96/EC, measuring tools that are no longer usable, and ac-cording to the European Guide-line 2006/66/EC, defective or used battery packs/batteries, must be collected separately and disposed of in an environmentally correct manner.

Batteries no longer suitable for use can be directly returned at:

Great Britain

Robert Bosch Ltd. (B.S.C.)

P.O. Box 98

Broadwater Park

North Orbital Road

Denham

Uxbridge

UB 9 5HJ

Tel. Service: +44 (0844) 736 0109

Fax: +44 (0844) 736 0146

E-Mail:

Battery packs/batteries:

Ni-MH: Nickel metal hydride Subject to change without notice.

Robert Bosch GmbH Power Tools Division

70745 Leinfelden-Echterdingen Germany

www.bosch-pt.com

2 610 A14 633 (2010.09) T / 458 XXX