Bosch GSB 162-2 RE Professional Impact Drill Instruction Manual

Safety Instructions

General Power Tool Safety Warnings

WARNING

Read all safety warnings, instructions, illustrations, and specifications provided with this power tool. Failure to follow all instructions listed below may result in electric shock, fire, and/ or serious injury.

Save all warnings and instructions for future reference. The term “power tool” in the warnings refers to your mains-operated (corded) power tool or battery-operated (cordless) power tool.

Work area safety

- Keep the work area clean and well-lit. Cluttered or dark areas invite accidents.

- Do not operate power tools in explosive atmospheres, such as in the presence of flammable liquids, gases, or dust. Power tools create sparks that may ignite dust or fumes.

- Keep children and bystanders away while operating a power tool. Distractions can cause you to lose control.

Electrical safety

- Power tool plugs must match the outlet. Never modify the plug in any way. Do not use any adapter plugs with earthed (grounded) power tools. Unmodified plugs and matching outlets will reduce the risk of electric shock.

- Avoid body contact with earthed or grounded surfaces, such as pipes, radiators, ranges, and refrigerators. There is an increased risk of electric shock if your body is earthed or grounded.

- Do not expose power tools to rain or wet conditions. Water entering a power tool will increase the risk of electric shock.

- Do not abuse the cord. Never use the cord for carrying, pulling, or unplugging the power tool. Keep cord away from heat, oil, sharp edges, or moving parts. Damaged or entangled cords increase the risk of electric shock.

- When operating a power tool outdoors, use an extension cord suitable for outdoor use. The use of a cord suitable for outdoor use reduces the risk of electric shock.

- If operating a power tool in a damp location is unavoidable, use a residual current device (RCD) protected supply. The use of an RCD reduces the risk of electric shock.

Personal safety

- Stay alert, watch what you are doing, and use common sense when operating a power tool. Do not use a power tool while you are tired or under the influence of drugs, alcohol, or medication. A moment of inattention while operating power tools may result in serious personal injury.

- Use personal protective equipment. Always wear eye protection. Protective equipment such as a dust mask, non-skid safety shoes, hard hat, or hearing protection used for appropriate conditions will reduce personal injuries.

- Prevent unintentional starting. Ensure the switch is in the off-position before connecting to a power source and/or battery pack, picking up or carrying the tool. Carrying power tools with your finger on the switch or energizing power tools that have the switch on invites accidents.

- Remove any adjusting key or wrench before turning the power tool on. A wrench or a key left attached to a rotating part of the power tool may result in personal injury.

- Do not overreach. Keep proper footing and balance at all times. This enables better control of the power tool in unexpected situations.

- Dress properly. Do not wear loose clothing or jewelry. Keep your hair and clothing away from moving parts. Loose clothes, jewelry, or long hair can be caught in moving parts.

- If devices are provided for the connection of dust extraction and collection facilities, ensure these are connected and properly used. The use of dust collection can reduce dust-related hazards.

- Do not let familiarity gained from frequent use of tools allow you to become complacent and ignore tool safety principles. A careless action can cause severe injury within a fraction of a second.

Power tool use and care

- Do not force the power tool. Use the correct power tool for your application. The correct power tool will do the job better and safer at the rate at which it was designed.

- Do not use the power tool if the switch does not turn on and off. Any power tool that cannot be controlled with the switch is dangerous and must be repaired.

- Disconnect the plug from the power source and/or remove the battery pack, if detachable, from the power tool before making any adjustments, changing accessories, or storing power tools. Such preventive safety measures reduce the risk of starting the power tool accidentally.

- Store idle power tools out of the reach of children and do not allow persons unfamiliar with the power tool or these instructions to operate the power tool. Power tools are dangerous in the hands of untrained users.

- Maintain power tools and accessories. Check for misalignment or binding of moving parts, breakage of parts, and any other condition that may affect the power tool’s operation. If damaged, have the power tool repaired before use. Many accidents are caused by poorly maintained power tools.

- Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting edges are less likely to bind and are easier to control.

- Use the power tool, accessories and tool bits, etc. in accordance with these instructions, taking into account the working conditions and the work to be performed. Use of the power tool for operations different from those intended could result in a hazardous situation.

- Keep handles and grasping surfaces dry, clean, and free from oil and grease. Slippery handles and grasping surfaces do not allow for safe handling and control of the tool in unexpected situations.

Service

- Have your power tool serviced by a qualified repair person using only identical replacement parts. This will ensure that the safety of the power tool is maintained.

Safety Warnings for Drills

Safety instructions for all operations

- Wear ear protectors when impact drilling. Exposure to noise can cause hearing loss.

- Use the auxiliary handle(s). Loss of control can cause personal injury.

- Hold the power tool by insulated gripping surfaces, when performing an operation where the cutting accessory or fasteners may contact hidden wiring or its own cord. Cutting accessories or fasteners contacting a”live” wire may make exposed metal parts of the power tool “live” and could give the operator an electric shock.

Safety instructions when using long drill bits

- Never operate at a higher speed than the maximum speed rating of the drill bit. At higher speeds, the bit is likely to bend if allowed to rotate freely without contacting the workpiece, resulting in personal injury.

- Always start drilling at low speed and with the bit tip in contact with the workpiece. At higher speeds, the bit is likely to bend if allowed to rotate freely without contacting the workpiece, resulting in personal injury.

- Apply pressure only in direct line with the bit and do not apply excessive pressure. Bits can bend causing breakage or loss of control, resulting in personal injury.

Additional safety warnings

- Switch the power tool off immediately if the application tool becomes blocked. Be prepared for high torque reactions which cause kickback. The application tool becomes blocked when it becomes jammed in the workpiece or when the power tool becomes overloaded.

- Hold the power tool securely. When tightening and loosening screws be prepared for temporarily high torque reactions.

- Secure the workpiece. A workpiece clamped with clamping devices or in a vice is held more secure than by hand.

- Use suitable detectors to determine if utility lines are hidden in the work area or call the local utility company for assistance. Contact with electric lines can lead to fire and electric shock. Damaging a gas line can lead to an explosion. Penetrating a water line causes property damage or may cause an electric shock.

- Always wait until the power tool has come to a complete stop before placing it down. The application tool can jam and cause you to lose control of the power tool.

Products sold in GB only:

Your product is fitted with a BS 1363/A approved electric plug with an internal fuse (ASTA approved to BS 1362).

If the plug is not suitable for your socket outlets, it should be cut off and an appropriate plug fitted in its place by an authorized customer service agent. The replacement plug should have the same fuse rating as the original plug. The severed plug must be disposed of to avoid a possible shock hazard and should never be inserted into the main socket elsewhere.

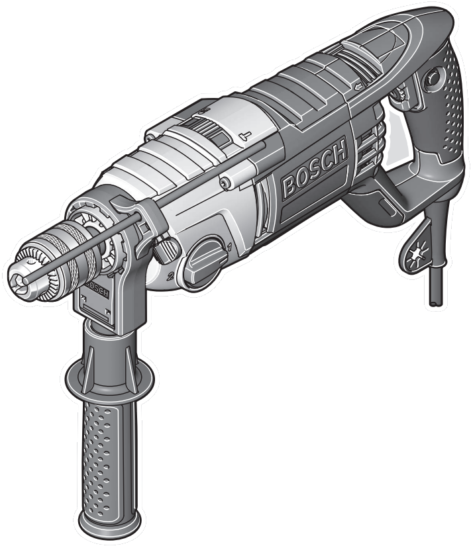

Product Description and Specifications

Failure to observe the safety and general instructions may result in electric shock, fire, and/or serious injury.

Please observe the illustrations at the beginning of this operating manual.

Intended Use

The power tool is intended for impact drilling in brick, concrete, and stone, dry drilling (not suitable for wet drilling) with diamond-studded core cutters in brick and lime-sand brick, as well as for drilling in wood, metal, ceramic, and plastic. Tools with electronic control and right/left rotation are also suitable for screwdriving and thread cutting.

Product Features

The numbering of the product features refers to the diagram of the power tool on the graphics page.

- Keyed chuck with automatic lock

- “Drilling/impact drilling” selector switch

- Rotational direction switch

- Lock-on button for on/off switch

- On/off switch

- Speed preselection thumbwheel

- Depth stop

- Gear selector switch

- Wing bolt for depth stop adjustment

- Auxiliary handle (insulated gripping surface)

- Handle (insulated gripping surface)

- Chuck key

- Screwdriver bit

- Universal bit holder

- Chuck key for keyed chuck with manual lock

- Keyed chuck with manual lock

- Open-ended spanner

a) Accessories shown or described are not included with the product as standard. You can find the complete selection of accessories in our accessories range.

b) Commercially available (not included in the scope of delivery)

Technical Data

Impact drill |

GSB 162-2 RE | |

| Article number | W | 3 601 A8B 0.. |

| Rated power input | W | 1 500 |

| Max. power output | 840 | |

| No-load speed | ||

| – First gear | min -1 | 0–750 |

| – Second gear | min -1 | 0–1800 |

| Rated speed | ||

| – First gear | min -1 | 555 |

| – Second gear | min -1 | 1 300 |

| Impact rate at no-load speed | ||

| – First gear | min -1 | 12 750 |

| – Second gear | min -1 | 30 600 |

| Spindle collar diameter | mm | 53 |

| Impact drill | GSB 162-2 RE | |

| Max. drilling diameter (first/second gear) | ||

| – Concrete | mm | 82/82 |

| – Masonry | mm | 162/82 |

| – Steel | mm | 20/14 |

| – Wood | mm | 50/32 |

| Chuck capacity | mm | 3–16 |

| Weight according to EPTA-Procedure 01:2014 | kg | 4.8 |

| Protection class | ||

The specifications apply to a rated voltage [U] of 230 V. These specifications may vary at different voltages and in country-specific models.

Noise/vibration information

Noise emission values were determined according to EN 62841-2-1.

Typically, the A-weighted noise level of the power tool is : Sound pressure level of 92 dB(A); a sound power level of 103 dB(A). Uncertainty K = 5 dB.

Wear hearing protection!

Vibration total values ah (triax vector sum) and uncertainty K determined according to EN 62841-2-1:

Drilling into metal: ah = 6.0 m/s² , K = 1.5 m/s²

Impact drilling into concrete: ah = 23.0 m/s² , K = 3.0 m/s²

Screwdriving: ah < 2.5 m/s² , K = 1.5 m/s²

Thread cutting: ah < 2.

5 m/s² , K = 1.5 m/s²

Drilling into concrete with a diamond drill: ah = 4.5 m/s² , K = 1.5 m/s²

The vibration level and noise emission value given in these

instructions have been measured in accordance with a

standardized measuring procedure and may be used to compare power tools. They may also be used for a preliminary estimation of vibration and noise emissions.

The stated vibration level and noise emission value represent the main applications of the power tool. However, if the power tool is used for other applications, with different application tools, or is poorly maintained, the vibration level and noise emission value may differ. This may significantly increase the vibration and noise emissions over the total working period.

To estimate vibration and noise emissions accurately, the times when the tool is switched off or when it is running but not actually being used should also be taken into account. This may significantly reduce vibration and noise emissions over the total working period.

Implement additional safety measures to protect the operator from the effects of vibration, such as servicing the power tool and application tools, keeping their hands warm, and organizing workflows correctly.

Assembly

- Pull the plug out of the socket before carrying out any work on the power tool.

Auxiliary handle (see figure A)

- Do not operate your power tool without the auxiliary handle (10).

You can adjust the auxiliary handle (10) to any of 12 positions in order to achieve a safe work posture that minimises fatigue.

Turn the lower gripping end of the auxiliary handle (10) in rotational direction ➊ and push the auxiliary handle (10) forward until you can swivel it into the required position.

Then pull the auxiliary handle (10) back again and turn the lower gripping end in a rotational direction ➋ to tighten it.

Setting the Drilling Depth

You can use the depth stop (7) to set the required drilling depth X.

Loosen the wing bolt for adjusting the depth stop (9) and insert the depth stop into the auxiliary handle (10).

Pull the depth stop (7) far enough out that the distance between the drill bit tip and the edge of the depth stop (7) corresponds to the required drilling depth X.

Retighten the wing bolt for adjusting the depth stop (9).

Changing the Tool

- Wear protective gloves when changing tools. The drill chuck may heat up significantly when it is used for long periods.

Keyed chuck with automatic lock (see figure D)

Open the keyed chuck (1) by turning it until the tool can be inserted.

Insert the tool. Insert the drill chuck key (12) into the corresponding holes of the keyed chuck (1) and clamp the tool evenly.

Keyed Chuck with Manual Lock (see figure E)

Open the keyed chuck (16) by turning it until the tool can be inserted. Insert the tool.

Insert the chuck key (15) into the corresponding holes of the keyed chuck (16) and clamp the tool evenly.

With the hexagon of the chuck key (15), turn the eccentric cam as far as it will go in the rotational direction ➋. This ensures sufficient tensioning force.

To remove the application tool, turn the eccentric cam in the rotational direction ➊ and open the keyed chuck (16) with the chuck key (15).

Screwdriving Tools

You should always use a universal bit holder (14) when using screwdriver bits (13). Only use screwdriver bits that fit the screw head.

For screwdriving, make sure the “drilling/impact drilling” selector switch (2) is always set to the “drilling” symbol.

Changing the drill chuck

- Pull the plug out of the socket before carrying out any work on the power tool.

Removing the Drill Chuck (see figure F)

To remove the keyed chuck (1), place an open-ended spanner (17) (width across flats: 17 mm) onto the spanner flat of the drive spindle.

Place the power tool on a firm surface, e.g. a workbench. Insert the chuck key (12) into one of the three holes of the keyed chuck (1) and release the keyed chuck (1) with this lever by turning it in a rotational direction ➊. A keyed chuck that is fixed in place can be released by applying light force to the chuck key (12). Remove the chuck key (12) from the keyed chuck and completely unscrew the keyed chuck.

Fitting the Drill Chuck (see figure G)

The keyed chuck is fitted in reverse order.

Dust/Chip Extraction

Dust from materials such as lead-containing coatings, some wood types, minerals, and metal can be harmful to one’s health. Touching or breathing in the dust can cause allergic

reactions and/or lead to respiratory infections of the user or bystanders.

Certain dust, such as oak or beech dust, is considered carcinogenic, especially in connection with wood-treatment additives (chromate, wood preservative). Materials containing

asbestos may only be worked by specialists.

– Provide for good ventilation of the working place.

– It is recommended to wear a P2 filter-class respirator.

Observe the relevant regulations in your country for the materials to be worked on.

- Avoid dust accumulation at the workplace. Dust can easily ignite.

Operation

Starting Operation

- Pay attention to the mains voltage. The voltage of the

power source must match the voltage specified on the

rating plate of the power tool. Power tools marked

with 230 V can also be operated with 220 V. - Products that are only sold in AUS and NZ: Use a residual current device (RCD) with a nominal residual current of 30 mA or less.

Setting the Rotational Direction (see figure H–I)

The rotational direction switch (3) is used to change the rotational direction of the power tool. However, this is not possible while the on/off switch (5) is being pressed.

Clockwise rotation: To drill and drive in screws, slide the rotational direction switch (3) to the left.

Anti-clockwise rotation: To loosen or unscrew screws and nuts, slide the rotational direction switch (3) to the right.

Setting the Operating Mode

Set the selector switch (2) to the “drilling” symbol.

Set the selector switch (2) to the “impact drilling” symbol.

The selector switch (2) clicks into place and can also be actuated when the motor is running.

Mechanical Gear Selection

- You can press the gear selector switch (8) with the power tool off or on. You should not do this at full load or maximum torque, however.

You can preselect two-speed ranges with the gear selector (8).

Gear I:

Low-speed range; for working with a large drilling diameter or for screwdriving.

Gear II:

High-speed range; for working with a small drilling diameter.

| Gear | Maximum drilling diameter | |

| 1 | > 100 mm | |

| 2 | < 100 mm |

Do not use annular cutters in hammer drilling mode. Set the selector switch (2) to the “drilling” symbol.

Switching on/off

To start the power tool, press and hold the on/off switch (5).

Press the lock-on button (4) to lock the on/off switch (5) in this position.

To switch off the power tool, release the on/off switch (5); or, if the switch is locked with the lock-on button (4), briefly press the on/off switch (5) and then release it.

Overload clutch

- If the application tool jams or snags, the power transmission to the drill spindle will be interrupted. Always hold the power tool firmly with both hands to withstand the forces this may create and adopt a position with a stable footing.

- Switch the power tool off immediately and remove the application tool if the power tool becomes blocked.

Switching on when the drilling tool is blocked may cause high torque reactions.

Adjusting the Speed/Impact Rate

You can adjust the speed/impact rate of the power tool when it is on by pressing the on/off switch (5) to vary extents.

Applying light pressure to the on/off switch (5) results in a low rotational speed/impact rate. Applying increasing pressure to the switch increases the speed/impact rate.

Preselecting the speed/impact rate

You can preselect the required speed/impact rate using the speed preselection thumbwheel (6), even during operation.

The required speed/impact rate is dependent on the material and the work conditions and can be determined by practical trials.

Restart Protection

The restart protection feature prevents the power tool from starting unintentionally after the power supply to it has been interrupted.

To restart the tool, set the on/off switch (5) to the “off” position and then switch the power tool on again.

Practical Advice

- Pull the plug out of the socket before carrying out any work on the power tool.

- Only apply the power tool to the screw/nut when the tool is switched off. Rotating tool inserts can slip off.

After working at a low speed for an extended period, you should operate the power tool at the maximum speed for approximately three minutes without load to cool it down. To drill into tiles, set the selector switch (2) to the “drilling” symbol. After drilling through the tile, set the selector switch to the “impact drilling” symbol and drill with impact. Use carbide drill bits when working with concrete, stone, and masonry.

When drilling into metal, only use sharpened HSS drills (HSS = high-speed steel) which are in perfect condition. The Bosch accessory range guarantees appropriate quality. Using the drill bit sharpener (accessory), you can effortlessly sharpen twist drill bits with a diameter of 2.5–10 mm.

Maintenance and Service

Maintenance and Cleaning

- Pull the plug out of the socket before carrying out any work on the power tool.

- To ensure safe and efficient operation, always keep the power tool and the ventilation slots clean.

In order to avoid safety hazards, if the power supply cord needs to be replaced, this must be done by Bosch or by an after-sales service center that is authorized to repair Bosch power tools.

After-Sales Service and Application Service

Our after-sales service responds to your questions concerning maintenance and repair of your product as well as spare parts. You can find explosion drawings and information on spare parts at: www.bosch-pt.com

The Bosch product use advice team will be happy to help you with any questions about our products and their accessories.

In all correspondence and spare parts orders, please always include the 10‑digit article number given on the nameplate of the product.

Great Britain

Robert Bosch Ltd. (B.S.C.)

P.O. Box 98

Broadwater Park

North Orbital Road

Denham Uxbridge

UB 9 5HJ

At www.bosch-pt.co.uk you can order spare parts or arrange the collection of a product in need of servicing or repair.

Tel. Service: (0344) 7360109

E-Mail:

You can find further service addresses at: www.bosch-pt.com/serviceaddresses

Disposal

The power tool, accessories, and packaging should be recycled in an environmentally friendly manner.

Only for EU countries:

According to the European Directive 2012/19/EU on Waste Electrical and Electronic Equipment and its implementation into national law, power tools that are no longer usable must be collected separately and disposed of in an environmentally friendly manner.

Only for the United Kingdom:

According to Waste Electrical and Electronic Equipment Regulations 2013 (2013/3113), power tools that are no longer usable must be collected separately and disposed of in an environmentally friendly manner.

Robert Bosch Power Tools GmbH

70538 Stuttgart

GERMANY

www.bosch-pt.com

1 609 92A 6N9 | (04.08.2021)

Bosch Power Tools