Makita M3602 Router Instruction Manual

makita M3602 Router Instruction Manual

makita M3602 Router Instruction

SPECIFICATIONS

| Model: | M3602 |

| Collet chuck capacity | 12 mm or 1/2″ |

| Plunge capacity | 0 – 60 mm |

| No load speed | 22,000 min-1 |

| Overall height | 300 mm |

| Net weight | 5.7 kg |

| Safety class | /II |

- Due to our continuing program of research and development, the specifications herein are subject to change without notice.

- Specifications may differ from country to country.

- Weight according to EPTA-Procedure 01/2014

Intended use

The tool is intended for flush trimming and profiling of wood, plastic and similar materials.

Power supply

The tool should be connected only to a power supply of the same voltage as indicated on the nameplate, and can only be operated on single-phase AC supply. They

are double-insulated and can, therefore, also be used from sockets without earth wire.

Noise

The typical A-weighted noise level determined according to EN62841-2-17:

Sound pressure level (LpA) : 84 dB(A)

Sound power level (LWA) : 95 dB (A)

Uncertainty (K) : 3 dB(A)

NOTE: The declared noise emission value(s) has been measured in accordance with a standard test method and may be used for comparing one tool with another.

NOTE: The declared noise emission value(s) may also be used in a preliminary assessment of exposure.

Vibration

The vibration total value (tri-axial vector sum) determined according to EN62841-2-17:

Work mode: cutting grooves in MDF Vibration emission (ah) : 3.1 m/s2 Uncertainty (K) : 1.5 m/s2

NOTE: The declared vibration total value(s) has been measured in accordance with a standard test method and may be used for comparing one tool with another.

NOTE: The declared vibration total value(s) may also be used in a preliminary assessment of exposure.

EC Declaration of Conformity

For European countries only

The EC declaration of conformity is included as Annex A to this instruction manual.

General power tool safety warnings

WARNING: Read all safety warnings, instructions, illustrations and specifications provided with this power tool. Failure to follow all instructions listed below

may result in electric shock, fire and/or serious injury.

Save all warnings and instructions for future reference.

The term “power tool” in the warnings refers to your mains-operated (corded) power tool or battery-operated (cordless) power tool.

Router safety warnings

- Hold the power tool by insulated gripping surfaces only, because the cutter may contact its own cord. Cutting a “live” wire may make exposed metal parts of the power tool “live” and could give the operator an electric shock.

- Use clamps or another practical way to secure and support the workpiece to a stable platform.

Holding the work by your hand or against the body leaves it unstable and may lead to loss of control. - The cutter bit shank must match the designed collet chuck.

- Only use a bit that is rated at least equal to the maximum speed marked on the tool.

- Wear hearing protection during extended period of operation.

- Handle the router bits very carefully.

- Check the router bit carefully for cracks or damage before operation. Replace cracked or damaged bit immediately.

- Avoid cutting nails. Inspect for and remove all nails from the workpiece before operation.

- Hold the tool firmly with both hands.

- Keep hands away from rotating parts.

- Make sure the router bit is not contacting the workpiece before the switch is turned on.

- Before using the tool on an actual workpiece, let it run for a while. Watch for vibration or wobbling that could indicate improperly installed bit.

- Be careful of the router bit rotating direction and the feed direction.

- Do not leave the tool running. Operate the tool only when hand-held.

- Always switch off and wait for the router bit to come to a complete stop before removing the tool from workpiece.

- Do not touch the router bit immediately after operation; it may be extremely hot and could burn your skin.

- Do not smear the tool base carelessly with thinner, gasoline, oil or the like. They may cause cracks in the tool base.

- Some material contains chemicals which may be toxic. Take caution to prevent dust inhalation and skin contact. Follow material supplier safety data.

- Always use the correct dust mask/respirator for the material and application you are working with.

- Place the tool on stable area. Otherwise falling accident may occur and cause an injury.

- Keep cord away from your foot or any objects. Otherwise an entangled cord may cause a falling accident and result in personal injury.

SAVE THESE INSTRUCTIONS.

WARNING: DO NOT let comfort or familiarity with product (gained from repeated use) replace strict adherence to safety rules for the subject product. MISUSE or failure to follow the safety

rules stated in this instruction manual may cause serious personal injury.

FUNCTIONAL DESCRIPTION

Adjusting the depth of cut

Place the tool on a flat surface. Loosen the lock lever and lower the tool body until the router bit just touches the flat surface.

Tighten the lock lever to lock the tool body. While pressing the fast-feed button, move the stopper pole up or down until the desired depth of cut is obtained. Minute depth adjustments can be obtained by turning the stopper pole (1.5 mm (1/16″) per turn).

- 1: 1. Nylon nut 2. Stopper pole 3. Fast-feed button

- Adjusting hex bolt 5. Stopper block 6. Lock lever

Nylon nut For tool without the knob

The upper limit of the tool body can be adjusted by turning the nylon nut. Do not lower the nylon nut too low. The router bit will protrude dangerously.

For tool with the knob

By turning the knob, the upper limit of the tool body can be adjusted. When the tip of the router bit is retracted more than required in rela- tion to the base plate surface, turn the knob to lower the upper limit.

- 2: 1. Knob

Stopper block

As the stopper block has three adjusting hex bolts which raise or lower 0.8 mm per turn, you can easily obtain three different depths of cut without readjusting the stopper pole.

- 3: 1. Stopper pole 2. Adjusting hex bolt

- Stopper block

Adjust the lowest adjusting hex bolt to obtain the deepest depth of cut, following the method of “Adjusting depth of cut”. Adjust the two remaining adjusting hex bolts to obtain shal- lower depths of cut. The differences in height of these adjust- ing hex bolts are equal to the differences in depths of cut.

To adjust the adjusting hex bolts, turn the adjusting hex bolts with a screwdriver or wrench. The stopper block is also convenient for making three passes with progres- sively deeper bit settings when cutting deep grooves.

Switch action

|

To start the tool, move the switch lever to the I position. To stop the tool, move the switch lever to the O position.

- 4: 1. Switch lever

Electronic function

The tool is equipped with the electronic functions for easy operation.

Indication lamp

- 5: 1. Indication lamp

The indication lamp lights up green when the tool is plugged. If the indication lamp does not light up, the mains cord or the controller may be defective. The indi- cation lamp is lit but the tool does not start even if the tool is switched on, the carbon brushes may be worn out, or the controller, the motor or the ON/OFF switch may be defective.

Unintentional restart proof

The tool does not start with the switch lever is in the I position even when the tool is plugged.

At this time, the indication lamp blinks in red and shows the unintentional restart proof device is on function. To cancel the unintentional restart proof, move the switch lever to the O position.

Soft start feature

Soft-start feature minimizes start-up shock, and makes the tool start smoothly.

ASSEMBLY

CAUTION: Always be sure that the tool is switched off and unplugged before carrying out any work on the tool.

Installing or removing the router bit

Insert the router bit all the way into the collet cone. Press the shaft lock to keep the shaft stationary and use the wrench to tighten the collet nut securely. When using router bits with smaller shank diameter, first insert the appropriate collet sleeve into the collet cone, then install the router bit.

To remove the router bit, follow the installation proce- dure in reverse.

- 6: 1. Shaft lock 2. Wrench 3. Loosen 4. Tighten

NOTICE: Do not tighten the collet nut without inserting a router bit or install small shank bits without using a collet sleeve. Either can lead to breakage of the collet cone.

OPERATION

- 7: 1. Chip deflector

Set the tool base on the workpiece to be cut without the router bit making any contact. Then turn the tool on and wait until the router bit attains full speed. Lower the

tool body and move the tool forward over the workpiece surface, keeping the tool base flush and advancing smoothly until the cutting is complete.

When doing edge cutting, the workpiece surface should be on the left side of the router bit in the feed direction.

- 8: 1. Workpiece 2. Bit revolving direction

- View from the top of the tool 4. Feed direction

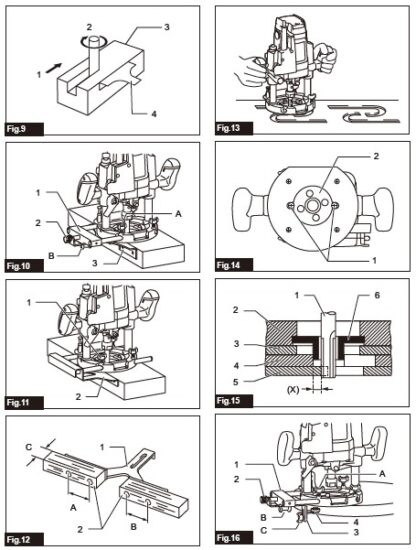

Straight guide

The straight guide is effectively used for straight cuts

when chamfering or grooving.

Straight guide (Type A)

Optional accessory

Install the straight guide on the guide holder with the thumb screw (B). Insert the guide holder into the holes in the tool base and tighten the thumb screw (A). To adjust the distance between the router bit and the straight guide, loosen the thumb screw (B) and turn the fine adjusting screw. At the desired distance, tighten the thumb screw (B) to secure the straight guide in place.

- 10: 1. Guide holder 2. Fine adjusting screw

- Straight guide

Straight guide (Type B)

Optional accessory

Insert the straight guide into the holes in the tool base and tighten the thumb screw. To adjust the distance between the router bit and the straight guide, loosen the thumb screw. At the desired distance, tighten the thumb screw to secure the straight guide in place.

- 11: 1. Thumb screw 2. Straight guide

When cutting, move the tool with the straight guide flush

with the side of the workpiece.

Wider straight guide of desired dimensions may be made by using the convenient holes in the guide to bolt on extra pieces of wood.

When using a large diameter router bit, attach pieces of wood to the straight guide which have a thickness of more than 15 mm (5/8″) to prevent the router bit from striking the straight guide.

- 12: 1. Straight guide 2. Wood

A=55 mm (2-3/16″) B=55 mm (2-3/16″)

C=15 mm (5/8″) or thicker

Templet guide

Optional accessory

The templet guide provides a sleeve through which the router

bit passes, allowing use of the router with templet patterns.

- 13

- Loosen the screws on the base, insert the templet guide and then tighten the screws.

- 14: 1. Screws 2. Templet guide

- Secure the templet to the workpiece. Place the tool on the templet and move the tool with the templet guide sliding along the side of the

- 15: 1. Router bit 2. Base 3. Base plate

- Templet 5. Workpiece 6. Templet guide

NOTE: The workpiece will be cut a slightly different size from the templet. Allow for the distance (X) between the router bit and the outside of the templet guide. The distance (X) can be calculated by using the following equation:

Distance (X) = (outside diameter of the templet guide – router bit diameter) / 2

Trimmer guide

Trimming, curved cuts in veneers for furniture and the like can be done easily with the trimmer guide. The guide roller rides the curve and assures a fine cut.

Trimmer guide (Type A)

Optional accessory

Install the trimmer guide on the guide holder with the thumb screw (B). Insert the guide holder into the holes in the tool base and tighten the thumb screw (A). To adjust the distance between the router bit and the trimmer guide, loosen the thumb screw (B) and turn the fine adjusting screw. When adjusting the guide roller up or down, loosen the thumb screw (C). After adjusting, tighten all the thumb screws securely.

- 16: 1. Guide holder 2. Fine adjusting screw

- Trimmer guide 4. Guide roller

Trimmer guide (Type B)

Optional accessory

Install the trimmer guide onto the straight guide using the thumb screws (B). Insert the straight guide into the holes in the tool base and tighten the thumb screw (A). To adjust the distance between the router bit and the trimmer guide, loosen the thumb screws (B). When adjusting the guide roller up or down, loosen the thumb screw (C). After adjusting, tighten all the thumb screws securely.

- 17: 1. Guide roller 2. Trimmer guide

When cutting, move the tool with the guide roller riding the side of the workpiece.

- 18: 1. Router bit 2. Guide roller 3. Workpiece

Dust cover (For tool with the knob)

Optional accessory

Dust cover prevents sawdust from being drawn into the tool in the inverted position. Install the dust cover as illustrated when using the tool with a router stand available in the market.

Remove it when using the tool in the normal position.

- 19: 1. Screw 2. Dust cover

Spacer (For tool with the knob)

Optional accessory

The spacer prevents the router bit from dropping into the chuck when replacing the router bit in the inverted position.

Insert the spacer as illustrated when using the tool with a router stand available in the market.

- 20: 1. Collet nut 2. Collet cone 3. Spacer

Dust extraction

Optional accessory

Use the dust nozzle for dust extraction.

- 21: 1. Dust nozzle

Installing the dust nozzle

- 22: 1. Support 2. Lock lever

- Raise the lock lever of the dust

- Place the dust nozzle onto the tool base so that its top will be caught in the hook on the tool

- Insert the supports on the dust nozzle into the

hooks on the front of the tool base.

- Push down the lock lever onto the tool

- Connect a vacuum cleaner to the dust

- 23

Removing the dust nozzle

- Raise the lock

- Pull the dust nozzle out of the tool base while holding the supports between thumb and

MAINTENANCE

To maintain product SAFETY and RELIABILITY, repairs, any other maintenance or adjustment should be performed by Makita Authorized or Factory Service Centers, always using Makita replacement parts.

|

Router bits Straight bit

► Fig.27

|

Unit:mm

|

Replacing carbon brushes

- 24: 1. Limit mark

Check the carbon brushes regularly.

Replace them when they wear down to the limit mark. Keep the carbon brushes clean and free to slip in the holders. Both carbon brushes should be replaced at the same time. Use only identical carbon brushes.

- Use a screwdriver to remove the brush holder

caps.

- Take out the worn carbon brushes, insert the new ones and secure the brush holder

- 25: 1. Brush holder cap

For tool with the knob

CAUTION:

Be sure to re-install the knob after inserting new carbon brush.

Release the lock lever and remove the knob by turning it counterclockwise.

Fig.26: 1. Kno

NOTE: The compression spring will come out of the knob, so be careful not to lose the compression spring

To maintain product SAFETY and RELIABILITY, repairs, any other maintenance or adjustment should be performed by Makita Authorized or Factory Service Centers, always using Makita replacement parts.

OPTIONAL ACCESSORIES

Straight bit ► Fig.27

| D | A | L1 | L2 |

| 6 | 20 | 50 | 15 |

| 1/4″ | |||

| 12 | 12 | 60 | 30 |

| 1/2″ | |||

| 12 | 10 | 60 | 25 |

| 1/2″ | |||

| 8 | 8 | 60 | 25 |

| 6 | 8 | 50 | 18 |

| 1/4″ | |||

| 6 | 6 | 50 | 18 |

| 1/4″ |

“U”Grooving bit

► Fig.28

| D | A | L1 | L2 | R |

| 6 | 6 | 50 | 18 | 3 |

“V”Grooving bit

► Fig.29

| D | A | L1 | L2 | θ |

| 1/4″ | 20 | 50 | 15 | 90° |

Dovetail bit ► Fig.30

| D | A | L1 | L2 | θ |

| 8 | 14.5 | 55 | 10 | 35° |

| 3/8″ | ||||

| 8 | 14.5 | 55 | 14.5 | 23° |

| 3/8″ | ||||

| 8 | 12 | 50 | 9 | 30° |

| 3/8″ |

Drill point flush trimming bit ► Fig.31

| D | A | L1 | L2 | L3 |

| 12 | 12 | 60 | 20 | 35 |

| 8 | 8 | 60 | 20 | 35 |

| 6 | 6 | 60 | 18 | 28 |

Drill point double flush trimming bit ► Fig.32

| D | A | L1 | L2 | L3 | L4 |

| 6 | 6 | 70 | 40 | 12 | 14 |

Slotting cutter ► Fig.33

| D | A | L1 | L2 |

| 12 | 30 | 55 | 6 |

| 1/2″ | |||

| 12 | 30 | 55 | 3 |

| 1/2″ |

Board-jointing bit ► Fig.34

| D | A1 | A2 | L1 | L2 | L3 |

| 12 | 38 | 27 | 61 | 4 | 20 |

Corner rounding bit ► Fig.35

| D | A1 | A2 | L1 | L2 | L3 | R |

| 6 | 25 | 9 | 48 | 13 | 5 | 8 |

| 6 | 20 | 8 | 45 | 10 | 4 | 4 |

Chamfering bit ► Fig.36

| D | A | L1 | L2 | L3 | θ |

| 6 | 23 | 46 | 11 | 6 | 30° |

| 6 | 20 | 50 | 13 | 5 | 45° |

| 6 | 20 | 49 | 14 | 2 | 60° |

► Fig.37

| D | A1 | A2 | L1 | L2 | L3 | C |

| 12 | 30 | 20 | 55 | 12 | 20 | 4 |

| 1/2″ |

Beading bit ► Fig.38

| D | A1 | A2 | L1 | L2 | L3 | R |

| 12 | 30 | 20 | 55 | 12 | 20 | 4 |

| 1/2″ |

Cove beading bit ► Fig.39

| D | A | L1 | L2 | R |

| 6 | 20 | 43 | 8 | 4 |

| 6 | 25 | 48 | 13 | 8 |

Ball bearing flush trimming bit ► Fig.40

| D | A | L1 | L2 |

| 6 | 10 | 50 | 20 |

| 1/4″ |

Ball bearing corner rounding bit ► Fig.41

| D | A1 | A2 | L1 | L2 | L3 | R |

| 6 | 15 | 8 | 37 | 7 | 3.5 | 3 |

| 6 | 21 | 8 | 40 | 10 | 3.5 | 6 |

| 1/4″ | 21 | 8 | 40 | 10 | 3.5 | 6 |

Ball bearing chamfering bit ► Fig.42

| D | A1 | A2 | L1 | L2 | θ |

| 6 | 26 | 8 | 42 | 12 | 45° |

| 1/4″ | |||||

| 6 | 20 | 8 | 41 | 11 | 60° |

Ball bearing beading bit ► Fig.43

| D | A1 | A2 | A3 | L1 | L2 | L3 | R |

| 6 | 20 | 12 | 8 | 40 | 10 | 5.5 | 4 |

| 6 | 26 | 12 | 8 | 42 | 12 | 4.5 | 7 |

Ball bearing cove beading bit ► Fig.44

| D | A1 | A2 | A3 | A4 | L1 | L2 | L3 | R |

| 6 | 20 | 18 | 12 | 8 | 40 | 10 | 5.5 | 3 |

| 6 | 26 | 22 | 12 | 8 | 42 | 12 | 5 | 5 |

Ball bearing roman ogee bit ► Fig.45

| D | A1 | A2 | L1 | L2 | L3 | R1 | R2 |

| 6 | 20 | 8 | 40 | 10 | 4.5 | 2.5 | 4.5 |

| 6 | 26 | 8 | 42 | 12 | 4.5 | 3 | 6 |

Double ball bearing round corner bit ► Fig.46

| D | A1 | A2 | A3 | L1 | L2 | L3 | R |

| 12 | 35 | 27 | 19 | 70 | 11 | 3.5 | 3 |

| 1/2″ |