Dewalt DW723-DWX724 Heavy-Duty Miter Saw Stand User Manual

INSTRUCTION MANUAL

DW723

Heavy-Duty Miter Saw Stand

DWX724

Compact Miter Saw Stand

DWX723/DWX724 Miter Saw Stands

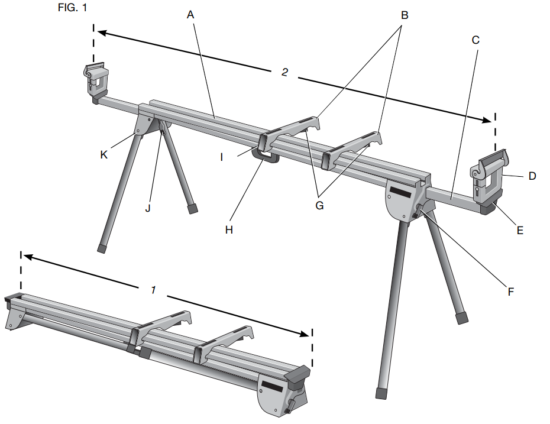

Components List

A. Beam

B. DW7231 Miter saw mounting brackets

C. Extension arm

D. DW7232 Workpiece support and length stop

E. Extension arm end cap

F. Extension arm lock lever

G. Release levers

H. Carry handle

I. Locking locator clip

J. Leg lock lever

K. Release button

| 1 | 1 | |

| DWX723 | 69.5″(1765.3 mm) | 151″ (3835.4 mm) |

| DWX724 | 43″ (1092.2 mm) | 100″ (2540 mm) |

Definitions: Safety Guidelines

The definitions below describe the level of severity for each signal word. Please read the manual and pay attention to these symbols.

NOTICE: Indicates a practice not related to personal injury that, if not avoided, may result in property damage.

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS OR ANY DEWALT TOOL, CALL US TOLL-FREE AT: 1-800-4-DEWALT

(1-800-433-9258)

Miter Saw Stand with Folding Legs DWX723/DWX724

This stand is designed for use with most miter saws. If you have any problem with alignment or mounting, call 1-800-4-DEWALT (1-800-433-9258).

Carton Contents

1 Miter saw stand (DWX723 or DWX724)

2 Miter saw mounting brackets (DW7231)

2 Workpiece support and length stop (DW7232)

1 Hardware bag

Tools Required

- Drill with a 3/8″ (9.5 mm) drill bit (Not required for DEWALT Miter Saws)

- Crosshead #2 screwdriver

- 1/2″ (13 mm) Wrench

Components (Fig. 1)

WARNING: Never modify the stand or any part of it. Damage or personal injury could result.

Refer to Figure 1 for Components List.

General Safety Instructions for Miter Saw Stands

- ALWAYS use eye protection. All users and bystanders must wear eye protection that conforms to ANSI Z87.1.

- ALWAYS check the stability of the miter saw stand and the miter saw attached to it before putting the stand or the saw into use.

- DO NOT mount any power tool other than a miter saw to this stand. Mounting other power tools to this stand could result in severe personal injury.

- DO NOT exceed the weight this stand can hold. The main center beam of the miter saw stand is designed to support 500 lbs. (227 kg.) safely in a work environment. It is unsafe to climb, sit or stand on the stand.

- Follow the mounting instructions carefully. Fasten the miter saw to the saw mounting brackets securely as instructed.

- DO NOT modify or use stand for operations for which it is unintended.

- DO NOT use the stand on uneven surfaces. The stand is designed to be used on a flat, stable surface.

- DO NOT use it on a slippery surface. The stand load capacity is greatly reduced when used on slippery surfaces.

Preparation (Fig. 2)

- Place the miter saw stand on the ground with the folded legs facing up.

- Depress the leg lock lever (J) or release button (K) and pull the leg up until the locking pin clicks into the place. Repeat on each leg.

- Lift the stand by the center beam and place it in an upright position. The stand should be stable and should not rock.

NOTE: Ensure all locking pins are engaged and the legs are locked in place.

ASSEMBLY

DW7232 Work Piece Support and Length Stops (Fig. 3–4)

a. The work support/stop (D) has a clamp (L) to capture the beam and keep it from being knocked off the beam by your material. The knob (M) may be locked by turning clockwise and the work support/stop is free to be repositioned when the knob is turned counterclockwise. Do not overtighten, firm pressure on the knob will hold the stop in place.

b. Adjust the height of the work support/stop (D) by loosening the knobs on both sides (N) and raising or lowering the top surface to align with a straight edge or level to the saw table. Tighten the knobs.

NOTE: If the work support height adjustment slips down when under a load, the weight limit of the work support has been exceeded. This weight limit is limited by the tightness of the height adjustment knobs. Do not tighten more than a finger tight.

c. The work support/stop (D) can also be installed in the end cap (E) at the end of the extension arms.

d. The length stop (O) may be rotated up to serve as a length stop or hold the end of long workpieces.

Adjustable Length Extension Arm (Fig. 5)

To lengthen the support surface, turn the extension arm lock lever counterclockwise to release the extendable extension arm.

Pull the extendable extension arm out to the desired length. Turn the extension arm lock lever clockwise to lock.

DW7231 DEWALT Miter Saw Mounting Method (Fig. 6, 7)

WARNING: To reduce the risk of injury, turn the unit off, and disconnect the machine from the power source before assembling the miter saw to the miter saw stand. An accidental start-up can cause injury.

WARNING: Stability Hazard. You must use the Universal Miter Saw Mounting Method when mounting a miter saw not manufactured by DEWALT to this miter saw stand.

WARNING: To reduce the risk of personal injury, be sure the miter saw is fully anchored on the stand.

WARNING: For your own safety, read and understand the miter saw instruction manual before using it. Failure to heed these warnings may result in personal injury and serious damage to the miter saw and the accessory.

- Place saw in operational position with the blade facing you. Align with a label on the mounting bracket showing the front.

- Place a spacer, such as a 2 x 4, under one side of the miter saw to hold the saw’s mounting feet above the work surface.

- Hold a mounting bracket under the saw and feed a carriage bolt (hardware bag) up through the bracket and the foot of the saw.

NOTE: See DW7231 Hardware Selection Chart for the correct mounting hardware procedures for DEWALT miter saws. Follow all instructions properly, otherwise, the miter saw’s table rotation may be obstructed.DW7231 HARDWARE SELECTION CHART Left Side Right Side DW703 1 1 DW705 1 1 DW706 1 1 DW708 1 2 DW712 1 2 DW713 1 1 DW715 1 1 DW716 1 1 DW717 2 1 DW718 3 2 1 = Long screw, Head on bottom 2 = Short screw, Head on bottom 3 = Long screw, Head on top - Once the carriage bolt (hardware bag) is installed per DW7231 Hardware Selection Chart, assemble a flat washer, lock washer, and nut onto the bolt. Tighten the bolts finger tight.

- Repeat the procedure on the other end of the bracket.

- Move the 2 x 4 to the other side of the saw to hold the other end of the saw up in order to access the saw base.

- Feed carriage bolts through the other bracket and the base of the saw as before. Ensure both brackets are parallel to each other.

- To place the saw onto the stand, grasp, and lift the saw by mounting bracket assembly by the release levers. These levers do not lock the saw laterally in place but merely serve as a means of mounting the saw to the beam.

- Approach the beam with saw/bracket assembly tilting toward your body slightly. Engage the concave front lip of the mounting bracket with the rounded edge of the beam. One of the brackets must engage the locator clip (I) to prohibit lateral movement of the saw during use.

- When the front edge of the beam and locking locator clip is engaged, a slight downward pivot will allow secure engagement of the release levers to the back of the beam. Rock the saw gently on the brackets to verify locking in position.

- Adjust the saw position as necessary to have the blade perpendicular to the beam when in the 0-degree miter position.

- Tighten the four nuts holding the saw to the brackets securely.

- Once the Plywood size has been determined, drill 3/8″ (9.5 mm) holes 1″ (25.5 mm) from the front corners of the plywood, 15″ (355 mm) apart, and 1″ (25.5 mm) from the sides.

- Place DW7231 mounting brackets on the stand:

a. Grasp and squeeze release levers (G).

b. Engage the concave front lip of the mounting bracket with the rounded front edge of the beam. One of the mounting brackets must be engaged in the locator clip (I) to prohibit lateral movement of the saw during use. - When the front edge of the beam and locator clip is engaged, a slight downward pivot will allow secure engagement of the release levers to the back of the beam. Follow the same procedure with the second mounting bracket at the appropriate position on the beam for the size of the plywood.

- Place plywood onto mounting brackets and align drilled holes with slots in mounting brackets. Refer to DW7231 HardwareSelection Chart and use either Method 1 or 2 to secure plywood to mounting brackets.

- Use a 1/2″ (13 mm) wrench to tighten hardware.

- The miter saw should be mounted to the plywood using holes in the miter saw base. The hardware size will be determined bythe holes in the miter saw base. Hardware should be 1-1/4″(31.8 mm) longer than the maximum height of the miter saw base at each mounting location.

b. Drill holes accordingly to the size of the hardware chosen.

NOTE: Hardware must be purchased to mount miter saw to plywood. All purchased hardware should be a minimum of Grade 5 or Class 8.8.

c. Secure miter saw to plywood as shown in Figure 9. Saw base (P), 3/4″ (19 mm) plywood (T), flat washer (Q), lock washer (S), and nut (R).

NOTE: Ensure a flat washer (Q) is used between plywood (T) and lock washer (S).

d. Tighten all hardware.

DW7231 Universal Miter Saw Mounting Method (Fig. 1, 7–9)

may result in personal injury and serious damage to the miter saw and the accessory.

NOTE: If you do not have a DEWALT miter saw, you must use 3/4″ (19 mm) plywood to mount your miter saw.

The plywood must be a minimum of 4″ (101.6 mm) wider than the largest width of the miter saw base. The plywood should be at least as deep as the smallest depth of the miter saw base or a minimum of 16″ (406.4 mm) if the miter saw base is smaller. Ensure the plywood

is square.

Carry Strap

If you purchase the carry strap accessory for DEWALT stands, use the square hole in the metal end to mount the accessory.

Locking Locator Clip (Fig. 1)

The locking locator clip (I) keeps the saw from sliding left or right during cutting operations. To move the clip, remove the saw/bracket assembly, loosen the screw in the center of the clip, slide it to the desired position and tighten the screw. You can then remount the saw/bracket in the new location.

Removing the Saw

Once the miter saw is fastened to the brackets, it can be removed by grasping the release levers, pulling up slightly to clear the beam, and can be set down on the nonmarring feet for transportation or cleaning.

Carry Handle (Fig. 10)

A handle has been supplied to transport the miter saw stand to and from the worksite.

WARNING: To reduce the risk of personal injury, DO NOT attempt to store or carry the stand with the saw attached. Loss of control may result.

Accessories

WARNING: Since accessories, other than those offered by DEWALT, have not been tested with this product, the use of such accessories with this tool could be hazardous. To reduce the risk of injury, do not create unstable conditions and use only with DEWALT miter saw stands.

COMPATIBLE PRODUCTS

DW7231 – Miter saw mounting brackets

DW7232 – Workpiece support and length stops

DW7029 – Wide workpiece support and length stops

DW7027 – Roller workpiece support

DW7028 – Extension support

DW7026 – Carry strap

Recommended accessories for use with your tool are available at extra cost from your local dealer or authorized service center. If you need assistance in locating any accessory, please contact DEWALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286, call 1-800-4-DEWALT (1-800-433-9258), or visit our website www.dewalt.com.

Repairs

To assure product SAFETY and RELIABILITY, repairs, maintenance and adjustments should be performed by a DEWALT factory service center, a DEWALT authorized service center, or other qualified service personnel. Always use identical replacement parts.

Three Year Limited Warranty

DEWALT will repair, without charge, any defects due to faulty materials or workmanship for three years from the date of purchase. This warranty does not cover part failure due to normal wear or tool abuse. For further detail on warranty coverage and warranty repair information, visit www.dewalt.com or call 1-800-4-DEWALT (1-800433-9258). This warranty does not apply to accessories or damage caused where repairs have been made or attempted by others.

This warranty gives you specific legal rights and you may have other rights which vary in certain states or

provinces.

In addition to the warranty, DEWALT tools are covered by our:

1 YEAR OF FREE SERVICE

DEWALT will maintain the tool and replace worn parts caused by

normal use, for free, any time during the first year after purchase.

90 DAY MONEY-BACK GUARANTEE

If you are not completely satisfied with the performance of your DEWALT Power Tool, Laser, or Nailer for any reason, you can return it within 90 days from the date of purchase with a receipt for a full refund – no questions asked.

LATIN AMERICA: This warranty does not apply to products sold in Latin America. For products sold in Latin America, see country-specific warranty information contained either in the packaging, call the local company, or see the website for warranty information.

FREE WARNING LABEL REPLACEMENT: If your warning labels become illegible or are missing, call 1-800-4-DEWALT (1-800-433-9258) for a free replacement.

DWX723 HEAVY-DUTY MITER SAW STAND

DEWALT INDUSTRIAL TOOL CO., BALTIMORE. MD 21286 U.S.A.

FOR SERVICE INFORMATION. CALL 1-800-4-DEWALT www.DEWALT.corn

DWX724 COMPACT MITER SAW STAND

DEWALT INDUSTRIAL TOOL CO. BALTIMORE. MO 21286 U.S.A.

FOR SERVICE INFORMATION, CALL 1-800-4-DEWALT www.DEWATT.com

FRONT

ALWAYS MOUNT SAW AS FAR FORWARD AS POSSIBLE. READ INSTRUCTIONS BEFORE USE. FOR USE WITH DEWALT MITER SAW STANDS. FASTEN MITER SAW SECURELY TO MOUNTING BRACKETS AND TO STAND PER INSTRUCTION LITERATURE. OPEN LEGS OF STAND FULLY BEFORE USE. ENSURE LOAD IS DIRECTLY OVER THE STAND BEAM. DO NOT CLIMB, SIT OR STAND ON A SAW STAND. DO NOT USE STAND ON UNEVEN, UNSTABLE, OR SLIPPERY SURFACES.