Makita AF506 Pneumatic Brad Nailer Instruction Manual

Pneumatic Brad Nailer

INSTRUCTION MANUAL

AF506

SPECIFICATIONS

| Model: | AF506 |

| Air pressure | 0.49 – 0.83 MPa (4.9 – 8.3 bar) |

| Nail gauge | 18 Ga. |

| Nail length | 15 mm – 50 mm |

| Nail capacity | 100 pcs. |

| Minimum hose diameter | 6.5 mm |

| Pneumatic tool oil | ISO VG32 or equivalent |

| Dimensions (L x W x H) | 250 mm x 70 mm x 256 mm |

| Net weight | 1.3 kg |

- Due to our continuing program of research and development, the specifications herein are subject to change without notice.

- Specifications may differ from country to country.

Symbols

The followings show the symbols used for the equipment. Be sure that you understand their meaning before use.

| Read the instruction manual. | |

| Wear safety glasses. | |

| Wear ear protection. | |

| Do not use scaffoldings or ladders. |

Intended use

The tool is intended for fastening on interior work and furniture work.

The tool is for high-volume professional applications only. Do not use it for any other purpose. It is not designed to drive fasteners on a hard surface like steel and concrete.

Noise

The typical A-weighted noise level is determined according to ISO11148-13(EN12549):

Sound pressure level (LpA) : 99 dB(A)

Sound power level (LWA) : 109 dB (A)

Uncertainty (K) : 1.5 dB(A)

NOTE: The declared noise emission value(s) has been measured in accordance with a standard test method and may be used for comparing one tool with another.

NOTE: The declared noise emission value(s) may also be used in a preliminary assessment of exposure.

Vibration

The vibration total value determined according to

ISO11148-13(ISO8662-11):

Vibration emission (ah) : 7.6 m/s²

Uncertainty (K) : 1.5 m/s2²

NOTE: The declared vibration total value(s) has been measured in accordance with a standard test method and may be used for comparing one tool with another.

NOTE: The declared vibration total value(s) may also be used in a preliminary assessment of exposure.

EC Declaration of Conformity

For European countries only

The EC declaration of conformity is included as Annex A to this instruction manual.

SAFETY WARNINGS

Pneumatic nailer/stapler safety warnings

WARNING: Read all safety warnings and all instructions. Failure to follow the warnings and instructions may result in serious injury, electric shock, and/or fire.

Save all warnings and instructions for future reference.

For personal safety and proper operation and maintenance of the tool, read this instruction manual before using the tool.

General safety

- Any other use except for the intended use of this tool is forbidden. Fastener driving tools with continual contact actuation or contact actuation shall only be used for production applications.

- Keep fingers away from the trigger when not operating this tool and when moving from one operating position to another.

- Multiple hazards. Read and understand the safety instructions before connecting, disconnecting, loading, operating, maintaining, changing accessories on, or working near

the tool. Failure to do so can result in serious bodily injury. - Keep all body parts such as hands and legs etc. away from the firing direction and ensure fastener cannot penetrate the workpiece into parts of the body.

- When using the tool, be aware that the fastener could deflect and cause injury.

- Hold the tool with a firm grasp and be prepared to manage recoil.

- Only technically skilled operators should use the fastener driving tool.

- Do not modify the fastener driving tool.

Modifications may reduce the effectiveness of safety measures and increase the risks to the operator and/or bystander. - Do not discard the instruction manual.

- Do not use a tool if the tool has been damaged.

- Be careful when handling fasteners, especially when loading and unloading, as the fasteners have sharp points which could cause injury.

- Always check the tool before use for broken, disconnected, or worn parts.

- Do not overreach. Only use in a safe working place.

Keep proper footing and balance at all times. - Keep bystanders away (when working in an area where there is a likelihood of traffic of people). Clearly mark off your operating area.

- Never point the tool at yourself or others.

- Do not rest your finger on the trigger when picking up the tool, moving between operating areas and positions, or walking, as resting your finger on the trigger can lead to inadvertent operation. For tools with selective actuation, always check the tool before use to ascertain the correct mode is selected.

- Only wear gloves that provide an adequate feel and safe control of triggers and any adjusting devices.

- When resting the tool, lay it down on a flat surface. If you use the hook equipped with the tool, hook the tool securely on the stable surface.

- Do not operate when under the influence of alcohol, drugs or the like.

Projectile hazards

- The fastener driving tool shall be disconnected when unloading fasteners, making adjustments, clearing jams, or changing accessories.

- During operation be careful that fasteners penetrate material correctly and cannot be deflected/misfired towards the operator and/or any bystanders.

- During operation, debris from the workpiece and the fastening/collation system may be discharged.

- Always wear protective goggles to protect your eyes from injury when using power tools.

The goggles must comply with ANSI Z87.1 in the USA, EN 166 in Europe, or AS/NZS 1336 in Australia/New Zealand. In Australia/New Zealand, it is legally required to wear a face shield to protect your face, too.It is an employer’s responsibility to enforce the use of appropriate safety protective equipment by the tool operators and by other persons in the immediate working area.

- The risks to others shall be assessed by the operator.

- Be careful with tools without workpiece contact as they can be fired unintentionally and injure the operator and/or bystander.

- Ensure the tool is always safely engaged on the workpiece and cannot slip.

- Wear hearing protection to protect your ears against exhaust noise and head protection.

Also, wear light but not loose clothing. Sleeves should be buttoned or rolled up. No necktie should be worn.

Operating hazards

- Hold the tool correctly: be ready to counteract normal or sudden movements such as recoil.

- Maintain a balanced body position and secure

- Appropriate safety glasses shall be used and appropriate gloves and protective clothing are

- Appropriate hearing protection shall be worn.

- Use the correct energy supply as directed in the instruction manual.

- Do not use the tool on moving platforms or back of trucks. The sudden movement of the platform may lose control of the tool and cause injury.

- Always assume that the tool contains

- Do not rush the job or force the tool. Handle the tool carefully.

- Watch your footing and maintain your balance with the tool. Make sure there is no one below when working in high locations, and secure the air hose to prevent danger if there is sudden jerking or catching.

- On rooftops and other high locations, drive fasteners as you move forward. It is easy to lose your footing if you drive fasteners while inching backward. When driving fasteners against the perpendicular surfaces, work from the top to the bottom. You can perform driving operations with less fatigue by doing so.

- A fastener will be bent or the tool can become jammed if you mistakenly drive the fastener on top of another fastener or strike a knot in the The fastener may be thrown and hit someone, or the tool itself can react danger ously. Place the fasteners with care.

- Do not leave the loaded tool or the air com pressor under pressure for a long time out in the sun. Be sure that dust, sand, chips and foreign matter will not enter the tool in the place where you leave it sitting.

- Never attempt to drive fasteners from both the inside and outside at the same time. Fasteners may rip through and/or fly off, presenting a grave

Repetitive motions hazards

- When using a tool for long periods, the operator may experience discomfort in the hands, arms, shoulders, neck, or other parts of the body.

- While using a tool, the operator should adopt a suitable but ergonomic posture. Maintain secure footing and avoid awkward or off-bal anced postures.

- If the operator experiences symptoms such as persistent or recurring discomfort, pain, throbbing, aching, tingling, numbness, burning sensation, or stiffness, do not ignore these warning signs. The operator should consult a qualified health profes sional regarding overall activities.

- The continuous use of the tool may cause repetitive strain injury due to recoil produced by the tool.

- To avoid repetitive strain injury, the operator should not overreach or use excessive force. Additionally, the operator should take a rest when feeling fatigue.

- Conduct a risk assessment regarding repeti tive motion hazards. It should focus on muscular-skeletal disorders and be preferentially based on the assumption that decreasing fatigue during work is effective in reducing

Accessory and consumable hazards

- Disconnect the energy supply to the tool, such as air or gas or battery as applicable, before changing/replacing accessories such as work- piece contact, or making any adjustments.

- Use only the sizes and types of accessories that are provided by the manufacturer.

- Use only lubricants recommended in this

Workplace hazards

- Slips, trips, and falls are major causes of work place injury. Be aware of slippery surfaces caused by the use of the tool and also of trip haz ards caused by the airline hose.

- Proceed with additional care in unfamiliar Hidden hazards may exist, such as electricity or other utility lines.

- This tool is not intended for use in potentially explosive atmospheres and is not insulated from coming into contact with electric power.

- Make sure there are no electrical cables, gas pipes, etc. that could cause a hazard if dam aged by the use of the tool.

- Keep the work area clean and well-lit. Cluttered or dark areas invite accidents.

- There may be local regulations concerning noise that must be complied with by keeping noise levels within prescribed limits. In certain cases, shutters should be used to contain

Dust and exhaust hazards

- Always check your surroundings. The air exhausted from the tool may blow dust or objects and hit the operator and/or bystanders.

- Direct the exhaust so as to minimize the distur bance of dust in a dust-filled environment.

- If dust or objects are emitted in the work area, reduce the emission as much as possible to reduce the health hazards and risk of injury.

Noise hazards

- Unprotected exposure to high noise levels can cause permanent, disabling, hearing loss and other problems such as tinnitus (ringing, buzz ing, whistling or humming in the ears).

- Conduct a risk assessment regarding noise hazards in the work area and implement appro priate controls for these hazards.

- Appropriate controls to reduce the risk may include actions such as damping materials to prevent workpieces from “ringing”.

- Use appropriate hearing protection.

- Operate and maintain the tool as recom mended in these instructions, to prevent an unnecessary increase in noise levels.

- Take noise reduction measures, for exam ple placing workpieces on sound damping

Vibration hazards

- The vibration emission during operation depends on the gripping force, the contact pressure force, the working direction, the adjustment of energy supply, the workpiece, and the workpiece support. Conduct a risk assess ment regarding vibration hazards and implement appropriate controls for these hazards.

- Exposure to vibration can cause disabling damage to the nerves and blood supply of the hands and arms.

- Wear warm clothing when working in cold conditions, and keep your hands warm and dry.

- If you experience numbness, tingling, pain, or whit ening of the skin in your fingers or hands, seek medical advice from a qualified occupational health professional regarding overall activities.

- Operate and maintain the tool as recom mended in these instructions, to prevent an unnecessary increase in vibration levels.

- Hold the tool with a light, but safe, grip because the risk from vibration is generally greater when the grip force is higher.

Additional warnings for pneumatic tools

- Compressed air can cause severe injury.

- Always shut off the air supply, and disconnect the tool from the air supply when not in use.

- Always disconnect the tool from the compressed air supply before changing accessories, making adjustments and/or repairs, when moving away from an operating area to a different area.

- Keep fingers away from the trigger when not operating the tool and when moving from one operating position to another.

- Never direct compressed air at yourself or anyone else.

- Whipping hoses can cause severe injury. Always check for damaged or loose hoses or fittings.

- Never carry a pneumatic tool by its hose.

- Never drag a pneumatic tool by its hose.

- When using pneumatic tools, do not exceed the maximum operating pressure ps max.

- Pneumatic tools should only be powered by compressed air at the lowest pressure required for the work process to reduce noise and vibration and minimize wear.

- Using oxygen or combustible gases for oper ating pneumatic tools creates a fire and explo sion hazard.

- Be careful when using pneumatic tools as the tool could become cold, affecting grip and

Safety devices

- Make sure all safety systems are in working order before operation. The tool must not operate if only the trigger is pulled or if only the contact arm is pressed against the wood. It must work only when both actions are performed. Test for possible faulty operation with fasteners unloaded and the pusher in fully pulled position.

- Securing the trigger in the ON position is very Never attempt to fasten the trigger.

- Do not attempt to keep the contact element or other safety devices depressed with tape or Death or serious injury may occur.

Service

- Perform cleaning and maintenance right after finish ing the job. Keep the tool in tip-top condition. Lubricate moving parts to prevent rusting and minimize friction-related wear. Wipe off all dust from the parts.

- Ask Makita authorized service center for peri odical inspection of the tool.

- To maintain product SAFETY and RELIABILITY, maintenance and repairs should be performed by Makita Authorized Service Centers, always using Makita replacement parts.

- Follow local regulations when disposing of the

SAVE THESE INSTRUCTIONS.

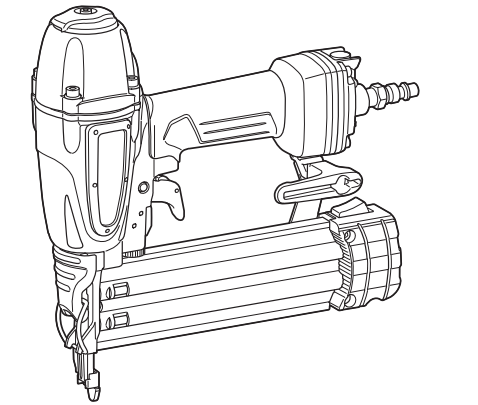

PARTS DESCRIPTION

► Fig.1: 1. Trigger 2. Hook 3. Nose adapter (contact element) 4. Magazine

INSTALLATION

Selecting compressor

- Nailing frequency (limes/min) 2. Compressor air output per minute (Umin) 3. 0.83 MPa (8.3 bar) 4. 0.74 MPa (7.4 bar) 5. 0.64 MPa (6.4 bar)

The air compressor must comply with the requirements of EN60335-2-34.

Select a compressor that has ample pressure and air output to assure cost-efficient operation. The graph shows the relation between nailing frequency, applicable pressure, and compressor air output.

Thus, for example, if nailing takes place at a rate of approximately 60 times per minute at a compression of 0.74 MPa (7.4 bar), a compressor with an air output over 55 liters/minute is required.

Pressure regulators must be used to limit air pressure to the rated pressure of the tool where air supply pressure exceeds the tool’s rated pressure. Failure to do so may result in serious injury to the tool operator or persons in the vicinity.

Selecting air hose

► Fig.2

Use an air hose as large and as short as possible to assure continuous, efficient nailing operation.

With an air pressure of 0.49 MPa (4.9 bar), an air hose with an internal diameter of over 6.5 mm and a length of less than 20 m is recommended when the interval between each nailing is 0.5 seconds.

Air supply hoses shall have a minimum working pressure rating of 1.03 MPa (10.3 bar) or 150 percent of the maximum pressure produced in the system whichever is higher.

Lubrication

► Fig.3

To ensure maximum performance, install an air set (oiler, regulator, air filter) as close as possible to the tool.

Adjust the oiler so that one drop of oil will be provided for every 50 nails.

When an air set is not used, oil the tool with pneumatic tool oil by placing 2 (two) or 3 (three) drops into the air fitting. This should be done before and after use.

For proper lubrication, the tool must be fired a couple of times after pneumatic tool oil is introduced.

► Fig.4: 1. Pneumatic tool oil

FUNCTIONAL DESCRIPTION

Adjusting the depth of nailing

► Fig.5: 1. Adjuster

To adjust the depth of nailing, turn the adjuster.

The depth of nailing is the deepest when the adjuster is turned fully in the A direction shown in the figure. It will become shallower as the adjuster is turned in the B direction.

If nails cannot be driven deep enough even when the adjuster is turned fully in the A direction, increase the air pressure.

If nails are driven too deep even when the adjuster is turned fully in the B direction, decrease the air pressure.

Generally speaking, the tool service life will be longer when the tool is used with lower air pressure and the adjuster set to a deeper depth of nail driving.

Hook

► Fig.6

► Fig.7: 1. Hook

The hook is convenient for hanging the tool temporarily.

Air duster

The air supplied to the tool can also be used as an air duster. You can clean the work area by pressing the button on the grip end.

► Fig.8: 1. Button

NOTICE: After using the air duster, the driving force of the tool will temporarily decline. Wait until the air pressure recovers in this case.

NOTICE: Perform a test blow if you use the air duster immediately after the oil was applied. The oil may be sprayed with the air.

ASSEMBLY

Loading nails

- Pull the sliding door while pressing down the lever to open the magazine.

► Fig.9: 1. Lever 2. Sliding door - Align the tip of nails with the groove of the magazine and push the nails to the firing opening.

► Fig.10: 1. Nail 2. Groove 3. Firing opening - Close the sliding door until it is locked.

Nose adapter

To prevent the surface of the workpiece from being scratched or damaged, use the nose adapter.

► Fig.11: 1. Nose adapter 2. Contact element A spare nose adapter is stored in the place shown in the figure.

► Fig.12: 1. Spare nose adapter

Connecting air hose

► Fig.13: 1. Air fitting 2. Air socket

Slip the aerial socket of the air hose onto the air fitting on the tool. Be sure that the air socket locks firmly into position when installed onto the air fitting.

A hose coupling must be installed on or near the tool in such a way that the pressure reservoir will discharge at the time the air supply coupling is disconnected.

OPERATION

Checking proper action before the operation

Before the operation, always check the following points.

— Make sure that the tool does not operate only by connecting the air hose.

— Make sure that the tool does not operate only by pulling the trigger.

— Make sure that the tool does not operate only by placing the contact element against the workpiece without pulling the trigger.

Driving nails

To drive a nail, place the contact element against the workpiece and pull the trigger.

► Fig.14

In order to avoid this unexpected nailing, perform as follows;

- Do not place the contact element against the workpiece with excessive force.

- Pull the trigger fully and hold it on for 1-2 seconds after nailing.

Removing jammed nails

- Open the sliding door and remove nails from the magazine.

► Fig.15 - With the sliding door kept open, pull the latch to open the door and then remove the nails.

► Fig.16: 1. Latch 2. Door

MAINTENANCE

NOTICE: Never use gasoline, benzene, thinner, alcohol, or the like. Discoloration, deformation, or cracks may result.

Nails

Handle nail strips and their box carefully. If the nail strips have been handled roughly, they may be out of shape, causing poor nail feed.

Avoid storing nails in a very humid or hot place or place exposed to direct sunlight.

Maintenance of nailer

Always check the tool for its overall condition and loose screws before operation. Tighten as required.

With the tool disconnected, make a daily inspection to assure free movement of the contact element and trigger. Do not use the tool if the contact element or trigger sticks or binds.

When the tool is not to be used for an extended period of time, lubricate the tool using pneumatic tool oil and store the tool in a safe place. Avoid exposure to direct

sunlight and/or humid or hot environments.

► Fig.17

Maintenance of compressor, air set, and air hose

After the operation, always drain the compressor tank and the air filter. If moisture is allowed to enter the tool, it may result in poor performance and possible tool

failure.

► Fig.18: 1. Drain cock

► Fig.19: 1. Air filter

Check regularly to see if there is sufficient pneumatic tool oil in the oiler of the air set. Failure to maintain sufficient lubrication will cause O-rings to wear quickly.

► Fig.20: 1. Oiler 2. Pneumatic tool oil

Keep the air hose away from heat (over 60°C, over 140°F), and away from chemicals (thinner, strong acids, or alkalis). Also, route the hose away from obstacles that may

become dangerously caught on during operation.

Hoses must also be directed away from sharp edges and areas which may lead to damage or abrasion to the hose.

To maintain product SAFETY and RELIABILITY, repairs, and any other maintenance or adjustment should be performed by Makita Authorized or Factory Service Centers, always using Makita replacement parts.

OPTIONAL ACCESSORIES

If you need any assistance with more details regarding these accessories, ask your local Makita Service

Center.

• Nails

• Air hose

• Safety goggles

NOTE: Some items in the list may be included in the tool package as standard accessories. They may differ from country to country.

Makita Europe N.V.

Jan-Baptist Vinkstraat 2,

3070 Kortenberg, Belgium

Makita Corporation

3-11-8, Sumiyoshi-cho,

Anjo, Aichi 446-8502 Japan

AF506-10L-1711

20190327