Dewalt DCS571 18V XR 115mm Brushless Compact Circular Saw Instruction Manual

DCS571

www.DeWALT.com

Original Instructions

115 mm CIRCULAR SAW

DCS571

Congratulations!

You have chosen a DeWALT tool. Years of experience, thorough product development and innovation make DeWALT one of the most reliable partners for professional power tool users.

Technical Data

| DCS571 | ||

| Voltage | VDC | 18 |

| Type | 1 | |

| Battery type | Li-Ion | |

| No-load speed | min-1 | 4500 |

| Blade diameter | mm | 115 |

| Maximum depth of cut | mm | 40. |

| Blade bore | mm | 10. |

| Bevel angle adjustment | 0°-45° | |

| Weight (without battery pack) | kg | 3. |

| Noise values and/or vibration values (triax vector sum) according to EN62841-2-5: | ||

| LpA (emission sound pressure level) | dB(A) | 91 |

| Lwa (sound power level) | dB(A) | 102 |

| K (uncertainty for the given sound level) | dB(A) | 3 |

| Vibration emission value ah = Uncertainty K = |

m/s2 m/s2 |

< 2.5 1.5 |

The vibration and/or noise emission level given in this information sheet has been measured in accordance with a standardised test given in EN62841 and may be used to compare one tool with another. It may be used for a preliminary assessment of exposure.

Identify additional safety measures to protect the operator from the effects of vibration and/or noise such as: maintain the tool and the accessories, keep the hands warm (relevant for vibration), organisation of work patterns.

EC‑Declaration of Conformity

Machinery Directive

115 mm Circular Saw

DCS571

DeWALT declares that these products described under

Technical Data are in compliance with: 2006/42/EC,

EN62841‑1:2015, EN62841‑2‑5:2014.

These products also comply with Directive 2014/30/EU and 2011/65/EU. For more information, please contact DeWALT at the following address or refer to the back of the manual.

The undersigned is responsible for compilation of the technical file and makes this declaration on behalf of DeWALT.

Markus Rompel

Vice President of Engineering, PTE‑Europe

DeWALT, Richard‑Klinger‑Straße 11,

65510, Idstein, Germany

25.10.2019

Definitions: Safety Guidelines

The definitions below describe the level of severity for each signal word. Please read the manual and pay attention to these symbols.

NOTICE: Indicates a practice not related to personal injury which, if not avoided, may result in property damage.

| Batteries | Chargers/Charge Times (Minutes)*** | ||||||||||||

| Cat # | \etc, | Ah | Weight (kg) | DCB104 | DCB107 | DCB112 | DCB113 | DCB115 | DCB116 | DCB117 | DCB118 | DCB132 | DCB119 |

| DCB546 | 18/54 | 6.0/2.0 | 1.08 | 60 | 270 | 170 | 140 | 90 | 80 | 40 | 60 | 90 | X |

| DCB547 | 18/54 | 9.0/3.0 | 1.46 | 75* | 420 | 270 | 220 | 135* | 110* | 60 | 75* | 135* | X |

| DCB548 | 18/54 | 12.0/4.0 | 1.46 | 120 | 540 | 350 | 300 | 180 | 150 | 80 | 120 | 180 | X |

| DCB549 | 18/54 | 15.0/5.0 | 2.12 | 125 | 730 | 450 | 380 | 230 | 170 | 90 | 125 | 230 | X |

| DCB181 | 18 | 1.5 | 0.35 | 22 | 70 | 45 | 35 | 22 | 22 | 22 | 22 | 22 | 45 |

| DCB182 | 18 | 4 | 0.61 | 60/40** | 185 | 120 | 100 | 60 | 60/45** | 60140** | 60/40** | 60 | 120 |

| DCB183/B/6 | 18 | 2 | 0.4 | 30 | 90 | 60 | 50 | 30 | 30 | 30 | 30 | 30 | 60 |

| DCB184/B/6 | 18 | 5 | 0.62 | 75150** | 240 | 150 | 120 | 75 | 75/60** | 75/50** | 75/50** | 75 | 150 |

| DCB185 | 18 | 1.3 | 0.35 | 22 | 60 | 40 | 30 | 22 | 22 | 22 | 22 | 22 | 40 |

| DCB187 | 18 | 3 | 0.54 | 45 | 140 | 90 | 70 | 45 | 45 | 45 | 45 | 45 | 90 |

| DCB189 | 18 | 4 | 0.54 | 60 | 185 | 120 | 100 | 60 | 60 | 60 | 60 | 60 | 120 |

| DCBP034 | 18 | 1.7 | 032 | 27 | 82 | 50 | 40 | 27 | 27 | 27 | 27 | 27 | 50 |

*Date code 201811475B or later

**Date code 201536 or later

***Battery charge times matrix provided for guidance only; charge times will vary depending on temperature and condition of batteries.

GENERAL POWER TOOL SAFETY WARNINGS

SAVE ALL WARNINGS AND INSTRUCTIONS FOR FUTURE REFERENCE.

The term “power tool” in the warnings refers to your mains-operated (corded) power tool or battery-operated (cordless) power tool.

- Work Area Safety

a ) Keep work area clean and well lit. Cluttered or dark areas invite accidents.

b ) Do not operate power tools in explosive atmospheres, such as in the presence of flammable liquids, gases or dust. Power tools create sparks which may ignite the dust or fumes.

c ) Keep children and bystanders away while operating a power tool. Distractions can cause you to lose control. - Electrical Safety

a ) Power tool plugs must match the outlet. Never modify the plug in any way. Do not use any adapter plugs with earthed (grounded) power tools. Unmodified plugs and matching outlets will reduce risk of electric shock.

b ) Avoid body contact with earthed or grounded surfaces such as pipes, radiators, ranges and refrigerators. There is an increased risk of electric shock if your body is earthed or grounded.

c ) Do not expose power tools to rain or wet conditions. Water entering a power tool will increase the risk of electric shock.

d ) Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the power tool. Keep cord away from heat, oil, sharp edges or moving parts. Damaged or entangled cords increase the risk of electric shock.

e ) When operating a power tool outdoors, use an extension cord suitable for outdoor use. Use of a cord suitable for outdoor use reduces the risk of electric shock.

f ) If operating a power tool in a damp location is unavoidable, use a residual current device (RCD) protected supply. Use of an RCD reduces the risk of electric shock. - Personal Safety

a ) Stay alert, watch what you are doing and use common sense when operating a power tool. Do not use a power tool while you are tired or under the influence of drugs, alcohol or medication. A moment of inattention while operating power tools may result in serious personal injury.

b ) Use personal protective equipment. Always wear eye protection. Protective equipment such as a dust mask, non-skid safety shoes, hard hat or hearing protection used for appropriate conditions will reduce personal injuries.

c ) Prevent unintentional starting. Ensure the switch is in the off-position before connecting to power source and/or battery pack, picking up or carrying the tool. Carrying power tools with your finger on the switch or energising power tools that have the switch on invites accidents.

d ) Remove any adjusting key or wrench before turning the power tool on. A wrench or a key left attached to a rotating part of the power tool may result in personal injury.

e ) Do not overreach. Keep proper footing and balance at all times. This enables better control of the power tool in unexpected situations.

f ) Dress properly. Do not wear loose clothing or jewellery. Keep your hair and clothing away from moving parts. Loose clothes, jewellery or long hair can be caught in moving parts.

g ) If devices are provided for the connection of dust extraction and collection facilities, ensure these are connected and properly used. Use of dust collection can reduce dust-related hazards.

h ) Do not let familiarity gained from frequent use of tools allow you to become complacent and ignore tool safety principles. A careless action can cause severe injury within a fraction of a second. - Power Tool Use and Care

a ) Do not force the power tool. Use the correct power tool for your application. The correct power tool will do the job better and safer at the rate for which it was designed.

b ) Do not use the power tool if the switch does not turn it on and off. Any power tool that cannot be controlled with the switch is dangerous and must be repaired.

c ) Disconnect the plug from the power source and/ or remove the battery pack, if detachable, from the power tool before making any adjustments, changing accessories, or storing power tools. Such preventive safety measures reduce the risk of starting the power tool accidentally.

d ) Store idle power tools out of the reach of children and do not allow persons unfamiliar with the power tool or these instructions to operate the power tool. Power tools are dangerous in the hands of untrained users.

e ) Maintain power tools and accessories. Check for misalignment or binding of moving parts, breakage of parts and any other condition that may affect the power tool’s operation. If damaged, have the power tool repaired before use. Many accidents are caused by poorly maintained power tools.

f ) Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting edges are less likely to bind and are easier to control.

g ) Use the power tool, accessories and tool bits, etc. in accordance with these instructions, taking into account the working conditions and the work to be performed. Use of the power tool for operations different from those intended could result in a hazardous situation.

h ) Keep handles and grasping surfaces dry, clean and free from oil and grease. Slippery handles and grasping surfaces do not allow for safe handling and control of the tool in unexpected situations. - Battery Tool Use and Care

a ) Recharge only with the charger specified by the manufacturer. A charger that is suitable for one type of battery pack may create a risk of fire when used with another battery pack.

b ) Use power tools only with specifically designated battery packs. Use of any other battery packs may create a risk of injury and fire.

c ) When battery pack is not in use, keep it away from other metal objects, like paper clips, coins, keys, nails, screws or other small metal objects, that can make a connection from one terminal to another. Shorting the battery terminals together may cause burns or a fire.

d ) Under abusive conditions, liquid may be ejected from the battery; avoid contact. If contact accidentally occurs, flush with water. If liquid contacts eyes, additionally seek medical help. Liquid ejected from the battery may cause irritation or burns.

e ) Do not use a battery pack or tool that is damaged or modified. Damaged or modified batteries may exhibit unpredictable behaviour resulting in fire, explosion or risk of injury.

f ) Do not expose a battery pack or tool to fire or excessive temperature. Exposure to fire or temperature above 130 °C may cause explosion.

g ) Follow all charging instructions and do not charge the battery pack or tool outside the temperature range specified in the instructions. Charging improperly or at temperatures outside the specified range may damage the battery and increase the risk of fire. - Service

a ) Have your power tool serviced by a qualified repair person using only identical replacement parts. This will ensure that the safety of the power tool is maintained.

b ) Never service damaged battery packs. Service of battery packs should only be performed by the manufacturer or authorized service providers.

Safety Instructions for All Saws

Cutting Procedures

a )

b ) Do not reach underneath the workpiece. The guard cannot protect you from the blade below the workpiece.

c ) Adjust the cutting depth to the thickness of the workpiece. Less than a full tooth of the blade teeth should be visible below the workpiece.

d ) Never hold the workpiece in your hands or across your leg while cutting. Secure the workpiece to a stable platform. It is important to support the work properly to minimise body exposure, blade binding, or loss of control.

e ) Hold the power tool by insulated gripping surfaces, when performing an operation where the cutting tool may contact hidden wiring. Contact with a “live” wire will also make exposed metal parts of the power tool “live” and could give the operator an electric shock.

f ) When ripping always use a rip fence or straight edge guide. This improves the accuracy of cut and reduces the chance of blade binding.

g ) Always use blades with correct size and shape (diamond versus round) of arbour holes. Blades that do not match the mounting hardware of the saw will run eccentrically, causing loss of control.

h ) Never use damaged or incorrect blade washers or bolt. The blade washers and bolt were specially designed for your saw, for optimum performance and safety of operation.

FURTHER SAFETY INSTRUCTIONS FOR ALL SAWS

Kickback Causes and Related Warnings

- Kickback is a sudden reaction to a pinched, jammed or misaligned saw blade, causing an uncontrolled saw to lift up and out of the workpiece toward the operator;

- When the blade is pinched or jammed tightly by the kerf closing down, the blade stalls and the motor reaction drives the unit rapidly back toward the operator;

- If the blade becomes twisted or misaligned in the cut, the teeth at the back edge of the blade can dig into the top surface of the wood causing the blade to climb out of the kerf and jump back toward the operator.

Kickback is the result of saw misuse and/or incorrect operating procedures or conditions and can be avoided by taking proper precautions as given below:

a ) Maintain a firm grip with both hands on the saw and position your arms to resist kickback forces. Position your body to either side of the blade, but not in line with the blade. Kickback could cause the saw to jump backwards, but kickback forces can be controlled by the operator, if proper precautions are taken.

b ) When blade is binding, or when interrupting a cut for any reason, release the trigger and hold the saw motionless in the material until the blade comes to a complete stop. Never attempt to remove the saw from the work or pull the saw backward while the blade is in motion or kickback may occur. Investigate and take corrective actions to eliminate the cause of blade binding.

c ) When restarting a saw in the workpiece, centre the saw blade in the kerf so that the saw teeth are not engaged into the material. If saw blade binds, it may walk up or kickback from the workpiece as the saw is restarted.

d ) Support large panels to minimise the risk of blade pinching and kickback. Large panels tend to sag under their own weight. Supports must be placed under the panel on both sides, near the line of cut and near the edge of the panel.

e ) Do not use dull or damaged blades. Unsharpened or improperly set blades produce narrow kerf causing excessive friction, blade binding and kickback.

f ) Blade depth and bevel adjusting locking levers must be tight and secure before making cut. If blade adjustment shifts while cutting, it may cause binding and kickback.

g ) Use extra caution when sawing into existing walls or other blind areas. The protruding blade may cut objects that can cause kickback.

SAFETY INSTRUCTIONS FOR SAWS WITH A PENDULUM BLADE GUARD

Lower Guard Function

a ) Check the lower guard for proper closing before each use. Do not operate the saw if the lower guard does not move freely and close instantly. Never clamp or tie the lower guard into the open position. If the saw is accidentally dropped, the lower guard may be bent. Raise the lower guard with the retracting handle and make sure it moves freely and does not touch the blade or any other part, in all angles and depths of cut.

b ) Check the operation of the lower guard spring. If the guard and the spring are not operating properly, they must be serviced before use. Lower guard may operate sluggishly due to damaged parts, gummy deposits, or a build-up of debris.

c ) The lower guard may be retracted manually only for special cuts such as “plunge cuts” and “compound cuts”. Raise the lower guard by retracting handle and as soon as blade enters the material, the lower guard must be released. For all other sawing, the lower guard should operate automatically.

d ) Always observe that the lower guard is covering the blade before placing the saw down on bench or floor. An unprotected, coasting blade will cause the saw to walk backwards, cutting whatever is in its path. Be aware of the time it takes for the blade to stop after switch is released.

Additional Safety Instructions for

Circular Saws

- Wear ear protectors. Exposure to noise can cause hearing loss.

- Wear a dust mask. Exposure to dust particles can cause breathing difficulty and possible injury.

- Do not use blades of larger or smaller diameter than recommended. For the proper blade rating refer to the Technical Data. Use only the blades specified in this manual, complying with EN 847-1.

- Use only saw blades that are marked with a speed equal or higher than the speed marked on the tool.

- Avoid overheating of blade tips.

- Install the dust extraction port onto the saw before use.

- Never use abrasive cut-off wheels.

- Do not use water feed attachments.

- Use clamps or another practical way to secure and support the workpiece to a stable platform. Holding the work by hand or against your body leaves it unstable and may lead to loss of control.

Residual Risks

In spite of the application of the relevant safety regulations and the implementation of safety devices, certain residual risks cannot be avoided. These are:

- Impairment of hearing.

- Risk of personal injury due to flying particles.

- Risk of burns due to accessories becoming hot during operation.

- Risk of personal injury due to prolonged use.

SAVE THESE INSTRUCTIONS

Chargers

DEWALT chargers require no adjustment and are designed to be as easy as possible to operate.

Electrical Safety

The electric motor has been designed for one voltage only. Always check that the battery pack voltage corresponds to the voltage on the rating plate. Also make sure that the voltage of your charger corresponds to that of your mains.

If the supply cord is damaged, it must be replaced only by DEWALT or an authorised service organisation.

Mains Plug Replacement

(U.K. & Ireland Only)

If a new mains plug needs to be fitted:

- Safely dispose of the old plug.

- Connect the brown lead to the live terminal in the plug.

- Connect the blue lead to the neutral terminal.

Follow the fitting instructions supplied with good quality plugs. Recommended fuse: 3 A.

Using an Extension Cable

An extension cord should not be used unless absolutely necessary. Use an approved extension cable suitable for the power input of your charger (see Technical Data). The minimum conductor size is 1 mm2 ; the maximum length is 30 m.

When using a cable reel, always unwind the cable completely.

Important Safety Instructions for All Battery Chargers

SAVE THESE INSTRUCTIONS: This manual contains important safety and operating instructions for compatible battery chargers (refer to Technical Data).

- Before using charger, read all instructions and cautionary markings on charger, battery pack, and product using battery pack.

NOTICE: Under certain conditions, with the charger plugged into the power supply, the exposed charging contacts inside the charger can be shorted by foreign material. Foreign materials of a conductive nature such as, but not limited to, steel wool, aluminum foil or any buildup of metallic particles should be kept away from charger cavities. Always unplug the charger from the power supply when there is no battery pack in the cavity. Unplug charger before attempting to clean

- DO NOT attempt to charge the battery pack with any chargers other than the ones in this manual. The charger and battery pack are specifically designed to work together.

- These chargers are not intended for any uses other than charging DeWALT rechargeable batteries. Any other uses may result in risk of fire, electric shock or electrocution.

- Do not expose charger to rain or snow.

- Pull by plug rather than cord when disconnecting charger. This will reduce risk of damage to electric plug and cord.

- Make sure that cord is located so that it will not be stepped on, tripped over, or otherwise subjected to damage or stress.

- Do not use an extension cord unless it is absolutely necessary. Use of improper extension cord could result in risk of fire,electric shock, or electrocution.

- Do not place any object on top of charger or place the charger on a soft surface that might block the ventilation slots and result in excessive internal heat. Place the charger in a position away from any heat source. The charger is ventilated through slots in the top and the bottom of the housing.

- Do not operate charger with damaged cord or plug— have them replaced immediately.

- Do not operate charger if it has received a sharp blow, been dropped, or otherwise damaged in any way. Take it to an authorised service centre.

- Do not disassemble charger; take it to an authorised service centre when service or repair is required. Incorrect reassembly may result in a risk of electric shock, electrocution or fire.

- In case of damaged power supply cord the supply cord must be replaced immediately by the manufacturer, its service agent or similar qualified person to prevent any hazard.

- Disconnect the charger from the outlet before attempting any cleaning. This will reduce the risk of electric shock. Removing the battery pack will not reduce this risk.

- NEVER attempt to connect two chargers together.

- The charger is designed to operate on standard 230V household electrical power. Do not attempt touse it on any other voltage. This does not apply to the vehicular charger.

Charging a Battery (Fig. B)

- Plug the charger into an appropriate outlet before inserting battery pack.

- Insert the battery pack 3 into the charger, making sure the battery pack is fully seated in the charger. The red (charging) light will blink repeatedly indicating that the charging process has started.

- The completion of charge will be indicated by the red light remaining ON continuously. The battery pack is fully charged and may be used at this time or left in the charger. To remove the battery pack from the charger, push the battery release button 13 on the battery pack.

NOTE: To ensure maximum performance and life of lithium‑ion battery packs, charge the battery pack fully before first use.

Charger Operation

Refer to the indicators below for the charge status of the battery pack.

Charge Indicators

| Charging | ||

| Fully Charged | ||

| Hot/Cold Pack Delay* |

* The red light will continue to blink, but a yellow indicator light will be illuminated during this operation. Once the battery pack has reached an appropriate temperature, the yellow light will turn off and the charger will resume the charging procedure.

The compatible charger(s) will not charge a faulty battery pack. The charger will indicate faulty battery by refusing to light.

NOTE: This could also mean a problem with a charger. If the charger indicates a problem, take the charger and battery pack to be tested at an authorised service centre.

Hot/cold Pack Delay

When the charger detects a battery pack that is too hot or too cold, it automatically starts a Hot/Cold Pack Delay, suspending charging until the battery pack has reached an appropriate temperature. The charger then automatically switches to the pack charging mode. This feature ensures maximum battery pack life.

A cold battery pack will charge at a slower rate than a warm battery pack. The battery pack will charge at that slower rate throughout the entire charging cycle and will not return to maximum charge rate even if the battery pack warms.

Electronic Protection system

XR Li‑Ion tools are designed with an Electronic Protection System that will protect the battery pack against overloading, overheating or deep discharge. The tool will automatically turn off if the Electronic Protection System engages. If this occurs, place the lithium‑ion battery pack on the charger until it is fully charged.

Wall Mounting

These chargers are designed to be wall mountable or to sit upright on a table or work surface. If wall mounting, locate the charger within reach of an electrical outlet, and away from a corner or other obstructions which may impede air flow. Use the back of the charger as a template for the location of the mounting screws on the wall. Mount the charger securely using drywall screws (purchased separately) at least 25.4 mm long with a screw head diameter of 7–9 mm, screwed into wood to an optimal depth leaving approximately 5.5 mm of the screw exposed. Align the slots on the back of the charger with the exposed screws and fully engage them in the slots.

Charger Cleaning Instructions

Battery Packs

Important Safety Instructions for All Battery Packs

When ordering replacement battery packs, be sure to include catalogue number and voltage.

The battery pack is not fully charged out of the carton. Before using the battery pack and charger, read the safety instructions below. Then follow charging procedures outlined.

READ ALL INSTRUCTIONS

- Do not charge or use battery in explosive atmospheres, such as in the presence of flammable liquids, gases or dust. Inserting or removing the battery from the charger may ignite the dust or fumes.

- Never force battery pack into charger. Do not modify battery pack in any way to fit into a non-compatible charger as battery pack may rupture causing serious personal injury.

- Charge the battery packs only in DeWALT chargers.

- DO NOT splash or immerse in water or other liquids.

- Do not store or use the tool and battery pack in locations where the temperature may reach or exceed 40 ˚C (104 ˚F) (such as outside sheds or metal buildings in summer).

- Do not incinerate the battery pack even if it is severely damaged or is completely worn out. The battery pack can explode in a fire. Toxic fumes and materials are created when lithium-ion battery packs are burned.

- If battery contents come into contact with the skin, immediately wash area with mild soap and water. If battery liquid gets into the eye, rinse water over the open eye for 15 minutes or until irritation ceases. If medical attention is needed, the battery electrolyte is composed of a mixture of liquid organic carbonates and lithium salts.

- Contents of opened battery cells may cause respiratory irritation. Provide fresh air. If symptoms persists, seek medical attention.

Transportation

WARNING: Fire hazard. Transporting batteries can possibly cause fire if the battery terminals inadvertently come in contact with conductive materials. When transporting batteries, make sure that the battery terminals are protected and well insulated from materials that could contact them and cause a short circuit.

NOTE: Lithium-ion batteries should not be put in checked baggage.

DeWALT batteries comply with all applicable shipping regulations as prescribed by industry and legal standards which include UN Recommendations on the Transport of Dangerous Goods; International Air Transport Association (IATA) Dangerous Goods Regulations, International Maritime Dangerous Goods (IMDG) Regulations, and the European Agreement Concerning The International Carriage of Dangerous Goods by Road (ADR). Lithium‑ion cells and batteries have been tested to section 38.3 of the UN Recommendations on the Transport of Dangerous Goods Manual of Tests and Criteria.

In most instances, shipping a DeWALT battery pack will be excepted from being classified as a fully regulated Class 9 Hazardous Material. In general, only shipments containing a lithium‑ion battery with an energy rating greater than 100 Watt Hours (Wh) will require being shipped as fully regulated Class 9. All lithium‑ion batteries have the Watt Hour rating marked on the pack. Furthermore, due to regulation complexities, DeWALT does not recommend air shipping lithium‑ion battery packs alone regardless of Watt Hour rating. Shipments of tools with batteries (combo kits) can be air shipped as excepted if the Watt Hour rating of the battery pack is no greater than 100 Whr.

Regardless of whether a shipment is considered excepted or fully regulated, it is the shipper’s responsibility to consult the latest regulations for packaging, labeling/marking and documentation requirements.

The information provided in this section of the manual is provided in good faith and believed to be accurate at the time the document was created. However, no warranty, expressed or implied, is given. It is the buyer’s responsibility to ensure that its activities comply with the applicable regulations.

Storage Recommendations

- The best storage place is one that is cool and dry away from direct sunlight and excess heat or cold. For optimum battery performance and life, store battery packs at room temperature when not in use.

- For long storage, it is recommended to store a fully charged battery pack in a cool, dry place out of the charger for optimal results.

NOTE: Battery packs should not be stored completely depleted of charge. The battery pack will need to be recharged before use.

Labels on Charger and Battery Pack

In addition to the pictographs used in this manual, the labels on the charger and the battery pack may show the following pictographs:

| Read instruction manual before use. | |

| See Technical Data for charging time. | |

| Do not probe with conductive objects. | |

| Do not charge damaged battery packs. | |

| Do not expose to water. | |

| Have defective cords replaced immediately. | |

| Charge only between 4 ˚C and 40 ˚C. | |

| Only for indoor use. | |

| Discard the battery pack with due care for the environment. | |

| Charge DeWALT battery packs only with designated DeWALT chargers. Charging battery packs other than the designated DeWALT batteries with a DeWALT charger may make them burst or lead to other dangerous situations. | |

| Do not incinerate the battery pack. |

Battery Type

The following tools operate on a 18 volt battery pack: DCS571 .

These battery packs may be used: DCB181, DCB182, DCB183,

DCB183B, DCB183G, DCB184, DCB184B, DCB184G, DCB185,

DCB187, DCB189, DCBP034, DCB546, DCB547, DCB548, DCB549.

Refer to Technical Data for more information.

Package Contents

The package contains:

1 Cordless circular saw

1 24‑tooth blade

1 Hex key

1 Rip guide

1 Dust extraction port

1 Charger (C, D, L, M, P, S, T, X models)

1 Li‑Ion battery pack (C1, D1, E1, L1, M1, P1, S1, T1, X1, Y1 models)

2 Li‑Ion battery packs (C2, D2, E2, L2, M2, P2, S2, T2, X2, Y2 models)

3 Li‑Ion battery packs (C3, D3, E3, L3, M3, P3, S3, T3, X3, Y3 models)

1 Instruction manual

NOTE: Battery packs, chargers and kitboxes are not included with N models. Battery packs and chargers are not included with NT models. B models include Bluetooth® battery packs.

NOTE: The Bluetooth® word mark and logos are registered trademarks owned by the Bluetooth®, SIG, Inc. and any use of such marks by DeWALT is under license. Other trademarks and trade names are those of their respective owners.

- Check for damage to the tool, parts or accessories which may have occurred during transport.

- Take the time to thoroughly read and understand this manual prior to operation.

Markings on Tool

The following pictograms are shown on the tool:

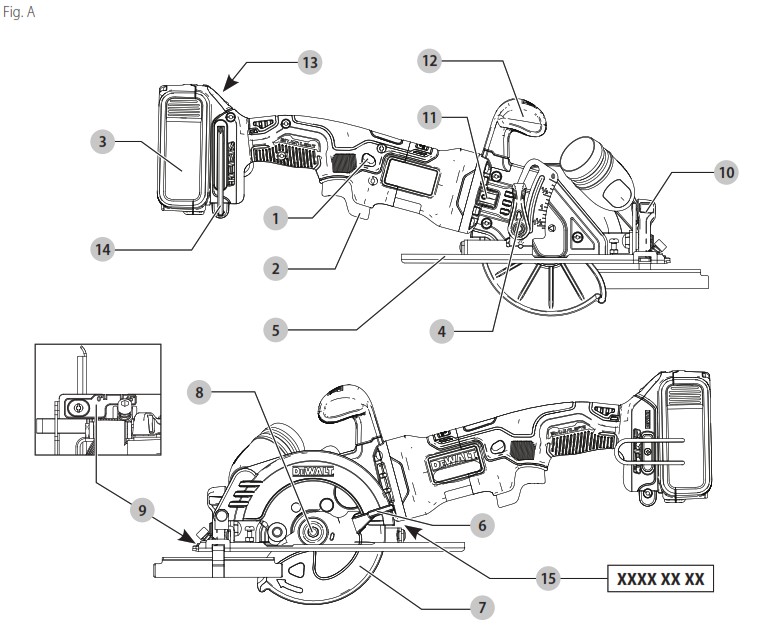

Date Code Position (Fig. A)

The date code 15 , which also includes the year of manufacture, is printed into the housing.

Example: 2021 XX XX

Year of Manufacture

Description (Fig. A)

| 1. Trigger switch lock‑off button 2. Trigger switch 3. Battery pack 4. Depth adjustment lever 5. Shoe 6. Lower blade guard retracting lever 7. Lower blade guard |

8. Blade clamping screw 9. Kerf indicator 10. Bevel adjustment knob 11. Blade lock button 12. Auxiliary handle 13. Battery release button 14. Hex key |

Intended Use

Your cordless circular saw has been designed for professional wood sawing applications.

DO NOT use under wet conditions or in the presence of flammable liquids or gases.

This circular saw is a professional power tool.

DO NOT let children come into contact with the tool. Supervision is required when inexperienced operators use this tool.

- Young children and the infirm. This appliance is not intended for use by young children or infirm persons without supervision.

- This product is not intended for use by persons (including children) suffering from diminished physical, sensory or mental abilities; lack of experience, knowledge or skills unless they are supervised by a person responsible for their safety. Children should never be left alone with this product.

ASSEMBLY AND ADJUSTMENTS

Inserting and Removing the Battery Pack from the Tool (Fig. B)

NOTE: Make sure your battery pack 3 is fully charged.

To Install the Battery Pack into the Tool Handle

- Align the battery pack 3 with the rails inside the tool’s handle (Fig. B).

- Slide it into the handle until the battery pack is firmly seated in the tool and ensure that you hear the lock snap into place.

To Remove the Battery Pack from the Tool

- Press the release button 13 and firmly pull the battery pack out of the tool handle.

- Insert battery pack into the charger as described in the charger section of this manual.

Fuel Gauge Battery Packs (Fig. B)

Some DeWALT battery packs include a fuel gauge which consists of three green LED lights that indicate the level of charge remaining in the battery pack.

To actuate the fuel gauge, press and hold the fuel gauge button 16 . A combination of the three green LED lights will illuminate designating the level of charge left. When the level of charge in the battery is below the usable limit, the fuel gauge will not illuminate and the battery will need to be recharged.

NOTE: The fuel gauge is only an indication of the charge left on the battery pack. It does not indicate tool functionality and is subject to variation based on product components, temperature and end‑user application.

Installing the Belt Hook (Fig. C)

IMPORTANT: When attaching or replacing the belt hook 19 , use only the screw 20 that is provided. Be sure to securely tighten the screw.

If the hook is not desired at all, it can be removed from the tool.

Trigger Switch (Fig. A)

Release the trigger switch lock‑off button 1 by pressing the button. Pull the trigger switch 2 to turn the motor on. Releasing the trigger switch turns the motor off.

Depth of Cut Adjustment (Fig. D)

- Loosen the depth adjustment lever 4 .

- Move the shoe 5 to obtain the correct depth of cut.

- Tighten the depth adjustment lever 4 .

- For the most efficient cutting action using a carbide tipped saw blade, set the depth adjustment so that about one half of a tooth projects below the surface of the wood to be cut.

NOTE: A method of checking for the correct cutting depth is shown in the inset in Figure D. Lay a piece of the material you plan to cut along the side of the blade and observe how much tooth projects beyond the material.

Bevel Adjustment (Fig. E)

The bevel angle can be adjusted between 0 ° and 45 °.

- Loosen the bevel adjustment knob 10 .

- Set the bevel angle by tilting the saw shoe 5 until the mark indicates the desired angle on the scale.

- Tighten the bevel adjustment knob 10 .

Shoe Adjustment for 90 ° Cuts (Fig. A, D, E)

- Adjust the saw to 0 ° bevel.

- Retract the blade guard using the lever 6 and place the saw on the blade side.

- Loosen the bevel adjustment knob 10 .

- Place a square against the blade and shoe to adjust the 90 ° setting.

- Turn the calibration screw 29 so that the shoe will stop at the proper angle.

- Confirm the accuracy of the setting by checking the squareness of an actual cut on a scrap piece of material.

Rip Guide Installation and Usage (Fig. A, F)

Ripping is the process of cutting wider boards into narrow strips, cutting the grain lengthways. Hand guiding is more difficult for this type of sawing and the use of the rip guide is recommended.

Assembly

- Loosen the rip fence guide locking screw 27 with the hex key 14 .

- Insert the rip guide 30 as shown in Figure F.

- Tighten the rip fence guide locking screw 27 securely.

Use the supplied rip guide only with the DCS571 circular saw. Use of this rip guide with other saws may increase the risk of kickback and injury.

Before making a cut, ensure the rip fence is securely fastened to the tool.

After installing the rip guide on the saw or after moving the guide to change the rip width setting, check the operation of the lower guard before starting the saw and making a cut to make sure that the rip guide does not affect proper guard operation.

Replacing the Saw Blade (Fig. A, G)

- Engage the blade lock button 11 and unscrew the blade clamping screw 8 by turning clockwise using the hex key supplied with the tool.

- Retract the lower blade guard 7 using the lever 6 and replace the blade. Reinstall the washers ( 17 , 18 ) in the correct position.

- Check the direction of rotation of the blade.

- Thread on the blade clamping screw 8 by hand to hold the washer in position. Turn counterclockwise.

- Press the blade lock button 11 while turning the spindle until the blade stops rotating.

- Tighten the blade clamping screw firmly using the hex key.

Blades

Do not use abrasive wheels or blades. A dull blade will cause slow inefficient cutting, overload on the saw motor, excessive splintering, and could increase the possibility of kickback.

If you need assistance regarding blades, please contact your local service center listed on the back of the manual.

| Blade | Diameter | Teeth | Application |

| DWA412TCT | 115 mm | 24 | Wood cutting |

| DWA412PCD | 115 mm | 4 | Fibre cement cutting |

Prior to Operation

- Make sure your battery pack is (fully) charged.

- Make sure the guards have been mounted correctly. The saw blade guard must be in closed position.

- Make sure the saw blade rotates in the direction of the arrow on the blade.

- Do not use excessively worn saw blades.

OPERATION

Instructions for Use

Instructions for Use

- Ensure the material to be sawn is secured in place.

- Apply only a gentle pressure to the tool and do not exert side pressure on the saw blade. If possible, work with the saw shoe pressed against the workpiece. This prevents damage to the blade and stops the tool from jerking and vibrating.

- Avoid overloading.

- Let the blade run freely for a few seconds before starting the cut.

Proper Hand Position (Fig. H)

ALWAYS use proper hand position as shown.

Proper hand position requires one hand on the main handle 21 or, if the auxiliary handle is attached, one hand on the main handle 21 and one hand on the auxiliary handle 12 .

Switching On and Off (Fig. A)

For safety reasons the trigger switch 2 of your tool is equipped with a lock‑off button 1 .

Press the lock‑off button to unlock the tool.

To run the tool, press the trigger switch 2 . As soon as the trigger switch is released the lock‑off switch is automatically activated to prevent unintended starting of the machine.

NOTICE: Do not switch the tool ON or OFF when the saw blade touches the workpiece or other materials.

Guiding the Tool (Fig. A, I)

- For optimum results, clamp the workpiece bottom up.

- Use the kerf indicator 9 to follow the line drawn on the workpiece. The kerf indicator lines up with the left side of the saw blade when set to 45 ° bevel. The kerf indicator lines up with the right side of the saw blade when set to 0 ° bevel.

- To adjust the kerf indicator 9 , loosen the kerf indicator screw 28 with the hex key 14 and move the indicator left or right as needed. Tighten screw when finished adjusting the indicator.

Dust Extraction (Fig. I–K)

The dust extraction port 24 allows you to connect the tool to an external dust extractor, either using the AirLock system, or a standard 35 mm dust extractor fitment. The AirLock connector 22 connects directly to DeWALT compatable tools and extractors.

Attach the dust extraction port 24 to the saw by sliding it onto the dust extraction mounting port 31 using a twisting motion until secure. The dust collection port is adjustable through 180 degrees.

- Ensure the collar on the AirLock connector is in the unlock position. (Refer to Figure J.) Align notches 23 on collar and AirLock connector as shown for unlock and lock positions.

- Push the AirLock connector onto the dust extraction port 24 .

- Rotate the collar to the locked position.

NOTE: The ball bearings inside collar lock into slot and secure the connection.The power tool is now securely connected to the dust extractor.

To Attach the Dust Bag (Fig. K)

- While holding the saw, fit the dust bag collar 26 to the dust extraction port 24 as shown in Figure K.

- Turn the collar 26 clockwise to lock the dust bag 25 in place.

To Empty the Dust Bag (Fig. K)

- While holding the saw, turn the collar 26 counterclockwise to unlock the dust bag 25 .

- Remove dust bag from the saw and gently shake or tap the dust bag to empty.

- Reattach the dust bag back onto the dust extraction port and lock into place by turning the dust bag collar clockwise.

You may notice that all the dust will not come free from the bag. This will not affect sanding performance but will reduce the saw’s dust collection efficiency. To restore your saw’s dust collection efficiency, depress the spring inside the dust bag when you are emptying it and tap it on the side of the trash can or dust receptacle.

Workpiece Support (Fig. L, M)

Figure L shows proper sawing position. Figure M shows an unsafe condition. Hands should be kept away from cutting area.

To avoid kickback, ALWAYS support board or panel NEAR the cut. DON’T support board or panel away from the cut .

ALWAYS DISCONNECT SAW BEFORE MAKING ANY

ADJUSTMENTS! Place the work with its “good” side—the one on which appearance is most important—down. The saw cuts upward, so any splintering will be on the work face that is up when you saw it.

MAINTENANCE

Your DeWALT power tool has been designed to operate over a long period of time with a minimum of maintenance. Continuous satisfactory operation depends upon proper tool care and regular cleaning.

The charger and battery pack are not serviceable.

Lubrication

Your power tool requires no additional lubrication.