Makita HM1511 Electric Breaker Instruction Manual

makita HM1511 Electric Breaker

SPECIFICATIONS

| Model: | HM1511 | HM1501 | HM1512 | HM1502 |

| Blows per minute | 1,300 min-1 | |||

| Overall length | 781 mm | 809 mm | ||

| Net weight | 19.2 kg | 18.4 kg | 20.4 kg | 19.7 kg |

| Safety class | /II | |||

| Soft no-load rotation function | – | – | ||

- Due to our continuing program of research and development, the specifications herein are subject to change without notice.

- Specifications may differ from country to country.

- The weight may differ depending on the attachment(s). The lightest and heaviest combination, according to EPTA-Procedure 01/2014, are shown in the table.

Intended use

The tool is intended for chiselling work in concrete, brick, stone and asphalt as well as for driving and com-pacting with appropriate accessories.

Power supply

The tool should be connected only to a power supply of the same voltage as indicated on the nameplate, and can only be operated on single-phase AC supply. They are double-insulated and can, therefore, also be used from sockets without earth wire.

Noise

The typical A-weighted noise level determined accord-ing to EN60745-2-6:

Model HM1511

Sound pressure level (LpA) : 85 dB(A) Sound power level (LWA) : 105 dB (A) Uncertainty (K) : 1.57 dB(A)

Model HM1501

Sound pressure level (LpA) : 84 dB(A) Sound power level (LWA) : 104 dB (A) Uncertainty (K) : 2.02 dB(A)

Model HM1512

Sound pressure level (LpA) : 84 dB(A) Sound power level (LWA) : 104 dB (A) Uncertainty (K) : 1.76 dB(A)

Model HM1502

Sound pressure level (LpA) : 85 dB(A) Sound power level (LWA) : 105 dB (A) Uncertainty (K) : 1.79 dB(A)

NOTE: The declared noise emission value(s) has been measured in accordance with a standard test method and may be used for comparing one tool with another.

NOTE: The declared noise emission value(s) may also be used in a preliminary assessment of exposure.

WARNING: Wear ear protection.

WARNING: The noise emission during actual use of the power tool can differ from the declared value(s) depending on the ways in which the tool is used especially what kind of workpiece is processed.

WARNING: Be sure to identify safety mea-sures to protect the operator that are based on an estimation of exposure in the actual conditions of use (taking account of all parts of the operating cycle such as the times when the tool is switched off and when it is running idle in addition to the trigger time).

Vibration

The vibration total value (tri-axial vector sum) deter-mined according to EN60745-2-6:

Model HM1511

- Work mode: chiselling

- Vibration emission (ah, Cheq): 6.5 m/s2

- Uncertainty (K) : 1.5 m/s2

Model HM1501

- Work mode: chiselling

- Vibration emission (ah,ID) : 14.5 m/s2

- Uncertainty (K) : 1.5 m/s2

Model HM1512

- Work mode: chiselling

- Vibration emission (ah,ID) : 6.5 m/s2

- Uncertainty (K) : 1.5 m/s2

Model HM1502

- Work mode: chiselling

- Vibration emission (ah,ID) : 14.5 m/s2

- Uncertainty (K) : 1.5 m/s2

NOTE: The declared vibration total value(s) has been measured in accordance with a standard test method and may be used for comparing one tool with another.

NOTE: The declared vibration total value(s) may also be used in a preliminary assessment of exposure.

WARNING: The vibration emission during actual use of the power tool can differ from the declared val-ue(s) depending on the ways in which the tool is used especially what kind of workpiece is processed.

WARNING: Be sure to identify safety measures to protect the operator that are based on an estima-tion of exposure in the actual conditions of use (tak-ing account of all parts of the operating cycle such as the times when the tool is switched off and when it is running idle in addition to the trigger time).

EC Declaration of Conformity

For European countries only The EC declaration of conformity is included as Annex A to this instruction manual.

SAFETY WARNINGS

General power tool safety warnings

WARNING: Read all safety warnings, instruc-tions, illustrations and specifications provided with this power tool. Failure to follow all instructions listed below may result in electric shock, fire and/or serious injury.

Save all warnings and instructions for future reference.

The term “power tool” in the warnings refers to your mains-operated (corded) power tool or battery-operated (cordless) power tool.

Electric Breaker safety warnings

- Wear ear protectors. Exposure to noise can cause hearing loss.

- Use auxiliary handle(s), if supplied with the tool. Loss of control can cause personal injury.

- Hold power tool by insulated gripping surfaces, when performing an operation where the cutting accessory may contact hidden wiring or its own cord. Cutting accessory contacting a “live” wire may make exposed metal parts of the power tool “live” and could give the operator an electric shock.

- Wear a hard hat (safety helmet), safety glasses and/or face shield. Ordinary eye or sun glasses are NOT safety glasses. It is also highly recommended that you wear a dust mask and thickly padded gloves.

- Be sure the bit is secured in place before operation.

- Under normal operation, the tool is designed to produce vibration. The screws can come loose easily, causing a breakdown or accident. Check tightness of screws carefully before operation.

- In cold weather or when the tool has not been used for a long time, let the tool warm up for a while by operating it under no load. This will loosen up the lubrication. Without proper warm-up, hammering operation is difficult.

- Always be sure you have a firm footing. Be sure no one is below when using the tool in high locations.

- Hold the tool firmly with both hands.

- Keep hands away from moving parts.

- Do not leave the tool running. Operate the tool only when hand-held.

- Do not point the tool at any one in the area when operating. The bit could fly out and injure someone seriously.

- Do not touch the bit, parts close to the bit, or workpiece immediately after operation; they may be extremely hot and could burn your skin.

- Some material contains chemicals which may be toxic. Take caution to prevent dust inhala-tion and skin contact. Follow material supplier safety data.

- Do not touch the power plug with wet hands.

- Before operation, make sure that there is no buried object such as electric pipe, water pipe or gas pipe in the working area. Otherwise, the bit may touch them, resulting an electric shock, electrical leakage or gas leak.

- Do not operate the tool at no-load unnecessarily.

SAVE THESE INSTRUCTIONS.

WARNING: DO NOT let comfort or familiarity with product (gained from repeated use) replace strict adherence to safety rules for the subject product. MISUSE or failure to follow the safety rules stated in this instruction manual may cause serious personal injury.

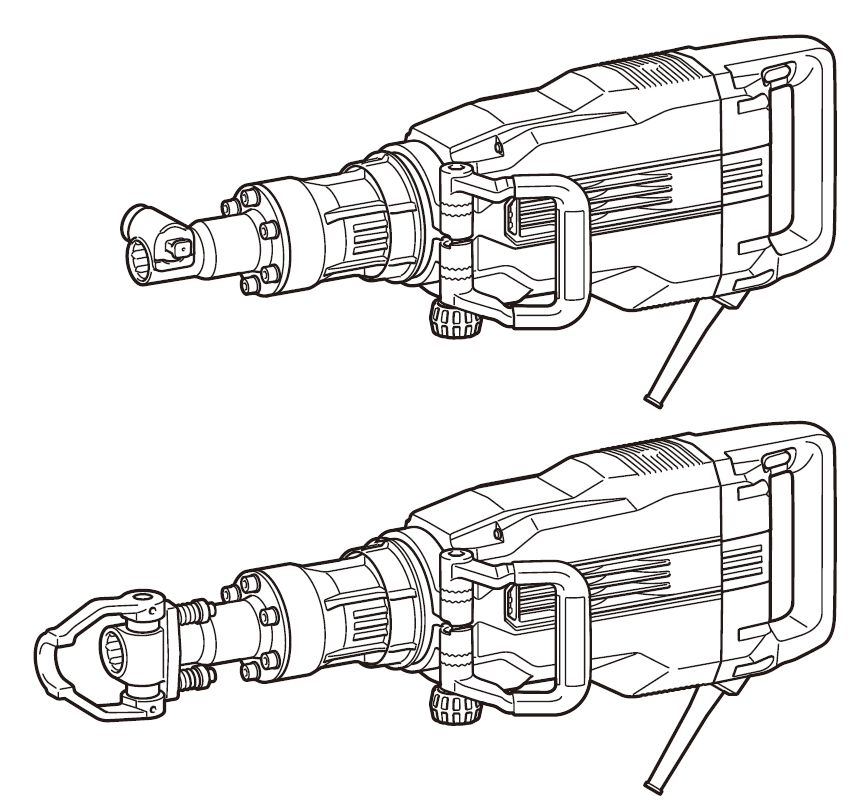

FUNCTIONAL DESCRIPTION

CAUTION: Always be sure that the tool is switched off and unplugged before adjusting or checking function on the tool.

Switch action

CAUTION: Before plugging in the tool, always check to see that the switch lever actuates prop-erly and returns to the “OFF” position.

CAUTION: Switch can be locked in “ON” posi-tion for ease of operator comfort during extended use. Apply caution when locking tool in “ON” position and maintain firm grasp on tool.

To start the tool, push the switch lever “ON (I)” on the left side of the tool. To stop the tool, push the switch lever “OFF (O)” on the right side of the tool.

Indicator lamp

The power-ON indicator lamp lights up in green when the tool is plugged. If the indicator lamp does not light up, the mains cord or the controller may be malfunction. The indicator lamp lights up but the tool does not start even if the tool is switched on, the carbon brushes may be worn out, or the controller, the motor or the switch may be malfunction The service indicator lamp flickers up in red when the carbon brushes are nearly worn out to indicate that the tool needs servicing. After approx. 8 hours of use, the motor will automatically be shut off.

- Power-ON indicator lamp (green) ► Fig.2:

- Service indicator lamp (red)

Electronic function

The tool is equipped with the electronic functions for easy operation.

- Soft no-load rotation function (For Model HM1511, HM1512 only) Blows at no load per minute becomes smaller than those on load in order to reduce vibration under no load, but this does not show trouble. Once operation starts with a bit against concrete, blows per minute increase. When temperature is low, the tool may not have this function even with the motor rotating.

- Soft start The soft-start function minimizes start-up shock, and makes the machine start smoothly.

ASSEMBLY

CAUTION: Always be sure that the tool is switched off and unplugged before carrying out any work on the tool.

Side handle (auxiliary handle)

CAUTION: Always use the side handle to ensure safe operation.

CAUTION: After installing or adjusting the side handle, make sure that the side handle is firmly secured.

The side handle can be swung 360° on the vertical and secured at any desired position. Loosen the clamp nut to swing the side handle to a desired position, and then tighten the clamp nut securely. Fig.3: 1. Side handle 2. Clamp nut

Installing or removing the bit

Grease

Clean the shank end of the bit and apply grease before installing the bit. Coat the shank end of the bit beforehand with a small amount of grease (about 0.5 – 1 g). This chuck lubrica-tion assures smooth action and longer service life. Fig.4: 1. Shank end 2. Grease

Installing the bit

CAUTION: Always assure that the bit is securely retained by attempting to pull the bit out of the tool holder after completing the above procedure.

For Model HM1511, HM1501 only

With the notched portion on the shank of the bit fac-ing toward the tool retainer, insert the bit into the tool holder as far as it will go. Then pull out and turn the tool retainer 180° to secure the bit. Fig.5: 1. Bit 2. Tool retainer 3. Tool holder

For Model HM1512, HM1502 only

This tool accepts bits either with or without a collar on its shank. Fig.6: 1. Bit with collar 2. Bit without collar

To install the bit, follow either procedure (1) or (2) described below.

NOTICE: The bit without a collar cannot be retained by procedure (1).

Removing the bit

To remove the bit, follow the installation procedure in reverse.

Dust extractor attachment

Optional accessory

The dust extractor attachment is intended for reducing blown-away dust and particles when chiseling in a ceramic material such as concrete.

- Install the hose holder (A).

Loosen the clamp nut, and then remove the hex bolt. Install the hose holder (A) between the hex bolt and the clamp nut by tightening the clamp nut firmly. Fig.11: 1. Hex bolt 2. Hose holder (A) 3. Clamp nut - Attach the hose holder (C) to the cord guard. Fig.12: 1. Cord guard 2. Hose holder (C)

- Attach the dust cover and the hose to the tool, and then fix the hose to the hose holders. ► Fig.13:

- Dust cover

- Hose

- Hose holder (A)

- Hose holder (C)

- Connect the hose to the hose of the vacuum cleaner with the hose joint.

NOTE: If the hose is not included, attach the dust cover to the cleaner’s joint or attach it to Makita’s hose ø28. - Adjust the distance between the dust cover and the tip of the chisel or bull point. For the self sharpening bull point, adjust the dust cover not to veil the grooves of the self sharpening bull point. For the bits other than the self sharpening bull point, the recommended distance is 30 mm to 100 mm. Fig.14: 1. Groove 2. 30 mm to 100 mm

OPERATION

CAUTION: Always use the side grip (auxiliary handle) and firmly hold the tool by both side grip and switch handle during operations.

CAUTION: Always make sure that the work-piece is secured before operation. Failure to prop-erly secure the workpiece may cause the workpiece to move resulting in injury.

CAUTION: Do not pull the tool out forcibly even the bit gets stuck. Loss of control may cause injury.

CAUTION: Do not leave the tool stabbed in the workpiece. Otherwise the tool may starts unin-tentionally and cause an injury.

Chipping/Scaling/Demolition

Hold the tool firmly with both hands. Turn the tool on and apply slight pressure on the tool so that the tool will not bounce around, uncontrolled. Pressing very hard on the tool will not increase the efficiency.

MAINTENANCE

CAUTION: Always be sure that the tool is switched off and unplugged before attempting to perform inspection or maintenance.

NOTICE: Never use gasoline, benzine, thinner, alcohol or the like. Discoloration, deformation or cracks may result.

To maintain product SAFETY and RELIABILITY, repairs, any other maintenance or adjustment should be performed by Makita Authorized or Factory Service Centers, always using Makita replacement parts.

Lubrication

CAUTION: This servicing should be performed by Makita Authorized Service Centers only. This tool requires no hourly or daily lubrication because it has a grease-packed lubrication system. It should be relubricated regularly. Send the complete tool to Makita Authorized or Factory Service Center for this lubrication service.

OPTIONAL ACCESSORIES

CAUTION: These accessories or attachments are recommended for use with your Makita tool specified in this manual. The use of any other accessories or attachments might present a risk of injury to persons. Only use accessory or attachment for its stated purpose.

If you need any assistance for more details regard-ing these accessories, ask your local Makita Service Center.

- Bull point

- Cold chisel

- Scaling chisel

- Clay spade

- Rammer

- Bit grease

- Dust extractor attachment

- Safety goggles

- Hammer carrier

NOTE: Some items in the list may be included in the tool package as standard accessories. They may differ from country to country.