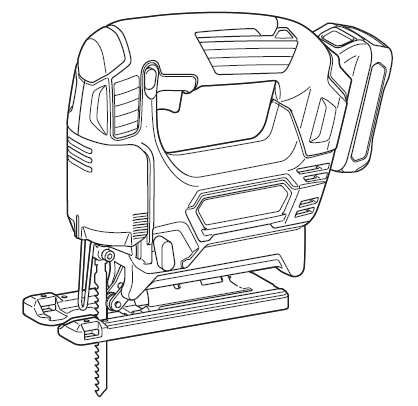

Makita JV101D Cordless Jig Saw Instruction Manual

makita JV101D Cordless Jig Saw

SPECIFICATIONS

| Model: | JV101D | |

| Length of stroke | 18 mm | |

| Strokes per minute | 0 – 2,900 min-1 | |

| Blade type | B type | |

| Max. cutting capacities | Wood | 65 mm |

| Mild steel | 2 mm | |

| Aluminum | 4 mm | |

| Rated voltage | D.C. 10.8 V – 12 V max | |

| Overall length (Depending on the battery) |

232 – 250 mm | |

| Net weight | 1.8 – 1.9 kg | |

- Due to our continuing program of research and development, the specifications herein are subject to change without notice.

- Specifications may differ from country to country.

- The weight may differ depending on the attachment(s), including the battery cartridge. The lightest and heaviest combination, according to EPTA-Procedure 01/2014, are shown in the table.

Applicable battery cartridge and charger

| Battery cartridge | BL1015 / BL1016 / BL1020B / BL1021B / BL1040B / BL1041B |

| Charger | DC10SA / DC10SB / DC10WC / DC10WD / DC18RE |

- Some of the battery cartridges and chargers listed above may not be available depending on your region of residence.

WARNING: Only use the battery cartridges and chargers listed above. Use of any other battery cartridges and chargers may cause injury and/or fire.

Intended use

The tool is intended for the sawing of wood, plastic and metal materials. As a result of the extensive accessory and saw blade program, the tool can be used for many purposes and is very well suited for curved or circular cuts.

Noise

The typical A-weighted noise level determined accord-ing to EN62841-2-11:

- Sound pressure level (LpA) : 80 dB(A)

- Sound power level (LWA) : 91 dB (A)

- Uncertainty (K) : 3 dB(A)

- NOTE: The declared noise emission value(s) has been measured in accordance with a standard test method and may be used for comparing one tool with another.

- NOTE: The declared noise emission value(s)

may also be used in a preliminary assessment of exposure. - WARNING: Wear ear protection.

- WARNING: The noise emission during actual use of the power tool can differ from the declared value(s) depending on the ways in which the tool is used especially what kind of workpiece is processed.

- WARNING: Be sure to identify safety measures to protect the operator that are based on an estimation of exposure in the actual conditions of use (taking account of all parts of the operating cycle such as the times when the tool is switched off and when it is running idle in addition to the trigger time).

Vibration

The vibration total value (tri-axial vector sum) deter-mined according to EN62841-2-11:

- Work mode: cutting boards

- Vibration emission (ah,B) : 7.0 m/s2

- Uncertainty (K) : 1.5 m/s2

- Work mode: cutting sheet metal

- Vibration emission (ah,M) : 5.5 m/s2

- Uncertainty (K) : 1.5 m/s2

- NOTE: The declared vibration total value(s) has been measured in accordance with a standard test method and may be used for comparing one tool with another.

- NOTE: The declared vibration total value(s) may also be used in a preliminary assessment of exposure.

- WARNING: The vibration emission during actual use of the power tool can differ from the declared value(s) depending on the ways in which the tool is used especially what kind of workpiece is processed.

- WARNING: Be sure to identify safety mea-sures to protect the operator that are based on an estimation of exposure in the actual conditions of use (taking account of all parts of the operating cycle such as the times when the tool is switched off and when it is running idle in addition to the trigger time).

EC Declaration of Conformity

For European countries only

The EC declaration of conformity is included as Annex A to this instruction manual.

General power tool safety warnings

WARNING: Read all safety warnings, instructions, illustrations and specifications provided

with this power tool. Failure to follow all instructions listed below may result in electric shock, fire and/or serious injury.

Save all warnings and instructions for future reference.

The term “power tool” in the warnings refers to your mains-operated (corded) power tool or battery-operated (cordless) power tool.

Cordless jig saw safety warnings

- Hold the power tool by insulated gripping surfaces, when performing an operation where the cutting accessory may contact hidden wiring. Cutting accessory contacting a “live” wire may make exposed metal parts of the power tool “live” and could give the operator an electric shock.

- Use clamps or another practical way to secure and support the workpiece to a stable platform. Holding the workpiece by hand or against your body leaves it unstable and may lead to loss of control.

- Always use safety glasses or goggles. Ordinary eye or sun glasses are NOT safety glasses.

- Avoid cutting nails. Inspect workpiece for any nails and remove them before operation.

- Do not cut oversize workpiece.

- Check for the proper clearance beyond the workpiece before cutting so that the blade will not strike the floor, workbench, etc.

- Hold the tool firmly.

- Make sure the blade is not contacting the workpiece before the switch is turned on.

- Keep hands away from moving parts.

- Do not leave the tool running. Operate the tool only when hand-held.

- Always switch off and wait for the blade to come to a complete stop before removing the blade from the workpiece.

- Do not touch the blade or the workpiece immediately after operation; they may be extremely hot and could burn your skin.

- Do not operate the tool at no-load unnecessarily.

- Some material contains chemicals which may be toxic. Take caution to prevent dust inhalation and skin contact. Follow material supplier safety data.

- Always use the correct dust mask/respirator for the material and application you are working with.

SAVE THESE INSTRUCTIONS.

WARNING: DO NOT let comfort or familiarity with product (gained from repeated use) replace strict adherence to safety rules for the subject product. MISUSE or failure to follow the safety rules stated in this instruction manual may cause serious personal injury.

Important safety instructions for battery cartridge

- Before using battery cartridge, read all instructions and cautionary markings on (1) battery charger, (2) battery, and (3) product using battery.

- Do not disassemble battery cartridge.

- If operating time has become excessively shorter, stop operating immediately. It may result in a risk of overheating, possible burns and even an explosion.

- If electrolyte gets into your eyes, rinse them out with clear water and seek medical attention right away. It may result in loss of your eyesight.

- Do not short the battery cartridge:

- Do not touch the terminals with any conductive material.

- Avoid storing battery cartridge in a container with other metal objects such as nails, coins, etc.

- Do not expose battery cartridge to water or rain.

A battery short can cause a large current

flow, overheating, possible burns and even a breakdown.

- Do not store the tool and battery cartridge in locations where the temperature may reach or exceed 50 °C (122 °F).

- Do not incinerate the battery cartridge even if it is severely damaged or is completely worn out. The battery cartridge can explode in a fire.

- Be careful not to drop or strike battery.

- Do not use a damaged battery.

- The contained lithium-ion batteries are subject to the Dangerous Goods Legislation requirements.

For commercial transports e.g. by third parties, forwarding agents, special requirement on packaging and labeling must be observed.

For preparation of the item being shipped, consult-ing an expert for hazardous material is required. Please also observe possibly more detailed national regulations.

Tape or mask off open contacts and pack up the battery in such a manner that it cannot move around in the packaging. - Follow your local regulations relating to disposal of battery.

- Use the batteries only with the products specified by Makita. Installing the batteries to non-compliant products may result in a fire, exces-sive heat, explosion, or leak of electrolyte.

SAVE THESE INSTRUCTIONS.

CAUTION: Only use genuine Makita batteries. Use of non-genuine Makita batteries, or batteries that have been altered, may result in the battery bursting causing fires, personal injury and damage. It will also void the Makita warranty for the Makita tool and charger.

Tips for maintaining maximum battery life

- Charge the battery cartridge before completely discharged. Always stop tool operation and charge the battery cartridge when you notice less tool power.

- Never recharge a fully charged battery cartridge. Overcharging shortens the battery service life.

- Charge the battery cartridge with room temperature at 10 °C – 40 °C (50 °F – 104 °F). Let a hot battery cartridge cool down before charging it.

FUNCTIONAL DESCRIPTION

CAUTION: Always be sure that the tool is switched off and the battery cartridge is removed before adjusting or checking function on the tool.

Installing or removing battery cartridge

CAUTION: Always switch off the tool before installing or removing of the battery cartridge.

CAUTION: Hold the tool and the battery car-tridge firmly when installing or removing battery cartridge. Failure to hold the tool and the battery cartridge firmly may cause them to slip off your hands and result in damage to the tool and battery cartridge and a personal injury.

Fig.1: 1. Red indicator 2. Button 3. Battery cartridge

To install the battery cartridge, align the tongue on the battery cartridge with the groove in the housing and slip it into place. Insert it all the way until it locks in place with a little click. If you can see the red indicator on the upper side of the button, it is not locked completely.

CAUTION: Always install the battery cartridge fully until the red indicator cannot be seen. If not, it may accidentally fall out of the tool, causing injury to you or someone around you.

CAUTION: Do not install the battery cartridge forcibly. If the cartridge does not slide in easily, it is not being inserted correctly.

Battery protection system

The tool is equipped with a battery protection system. This system automatically cuts off power to the motor to extend battery life.

The tool will automatically stop during operation if the tool and/or battery are placed under one of the following conditions:

Overloaded:

The tool is operated in a manner that causes it to draw an abnormally high current.

In this situation, turn the tool off and stop the application that caused the tool to become overloaded. Then turn the tool on to restart.

If the tool does not start, the battery is overheated. In this situation, let the battery cool before turning the tool on again.

Low battery voltage:

The remaining battery capacity is too low and the tool will not operate. If you turn the tool on, the motor runs again but stops soon. In this situation, remove and recharge the battery.

Indicating the remaining battery capacity

Only for battery cartridges with the indicator

Fig.2: 1. Indicator lamps 2. Check button

Selecting the cutting action

Fig.3: 1. Cutting action changing lever

This tool can be operated with an orbital or a straight line (up and down) cutting action. The orbital cutting action thrusts the jig saw blade forward on the cutting stroke and greatly increases cutting speed.

To change the cutting action, just turn the cutting action changing lever to the desired cutting action position. Refer to the table to select the appropriate cutting action.

| Position | Cutting action | Applications |

| 0 | Straight line cutting action | For cutting mild steel, stainless steel and plastics. |

| For clean cuts in wood and plywood. | ||

| I | Small orbit cutting action | For cutting mild steel, aluminum and hard wood. |

| II | Medium orbit cutting action | For cutting wood and plywood. |

| For fast cutting in aluminum and mild steel. | ||

| III | Large orbit cutting action | For fast cutting in wood and plywood. |

Switch action

CAUTION: Before installing the battery cartridge into the tool, always check to see that the switch trigger actuates properly and returns to the “OFF” position when released.

CAUTION: When not operating the tool, depress the lock-off button from A side to lock the switch trigger in the OFF position.

Fig.4: 1. Lock-off button 2. Switch trigger

To start the tool, depress the lock-off button from B side and pull the switch trigger.

Tool speed is increased by increasing pressure on the switch trigger. Release the switch trigger to stop. After use, always press in the lock-off button from A side.

ASSEMBLY

CAUTION: Always be sure that the tool is switched off and the battery cartridge is removed before carrying out any work on the tool.

Installing or removing jig saw blade

- CAUTION: Always clean out all chips or foreign matter adhering to the jig saw blade and/or blade holder. Failure to do so may cause insufficient tightening of the blade, resulting in a serious personal injury.

- CAUTION: Do not touch the jig saw blade or the workpiece immediately after operation. They may be extremely hot and could burn your skin.

- CAUTION: Always secure the jig saw blade firmly. Insufficient tightening of the blade may cause blade breakage or serious personal injury.

- CAUTION: Use only B type jig saw blades. Using blades other than B type causes insufficient tightening of the blade, resulting in a serious personal injury.

To install the jig saw blade, loosen the bolt counter-clockwise on the jig saw blade holder with the hex

wrench.

Fig.5: 1. Jig saw blade holder 2. Bolt 3. Hex wrench

roller. Then tighten the bolt clockwise to secure the blade.

Fig.6: 1. Bolt 2. Roller 3. Jig saw blade

NOTE: Occasionally lubricate the roller.

Hex wrench storage

Fig.7: 1. Hook 2. Hex wrench

figure to keep it from being lost.

First, insert the hex wrench into the hole. Then push it into the hook until it locked.

Dust cover

CAUTION: Always wear safety goggles even when operating the tool with the dust cover lowered.

Lower the dust cover to prevent chips from flying.

However, when making bevel cuts, raise it all the way.

Fig.8: 1. Dust cover

OPERATION

CAUTION: Always hold the base flush with the workpiece. Failure to do so may cause jig saw blade breakage, resulting in a serious injury.

CAUTION: Advance the tool very slowly when cutting curves or scrolling. Forcing the tool may cause a slanted cutting surface and jig saw blade breakage.

Fig.9: 1. Cutting line 2. Base

Bevel cutting

CAUTION: Always be sure that the tool is switched off and the battery cartridge is removed before tilting the base.

CAUTION: Raise the dust cover all the way before making bevel cuts.

With the base tilted, you can make bevel cuts at any angle between 0° and 45° (left or right).

Fig.10

Fig.11: 1. Hex wrench 2. Bolt 3. Base

Fig.12: 1. Edge 2. Graduation

Fig.13: 1. Hex wrench 2. Bolt 3. Base

Cutouts

Cutouts can be made with either of two methods “Boring a starting hole” or “Plunge cutting”.

Boring a starting hole

Fig.14

Insert the jig saw blade into this hole to start your cut.

Plunge cutting

Fig.15

- Tilt the tool up on the front edge of the base with the jig saw blade point positioned just above the work-piece surface.

- Apply pressure to the tool so that the front edge of the base will not move when you switch on the tool and gently lower the back end of the tool slowly.

- As the jig saw blade pierces the workpiece, slowly lower the base of the tool down onto the workpiece surface.

- Complete the cut in the normal manner.

Finishing edges

Fig.16

Metal cutting

Always use a suitable coolant (cutting oil) when cutting metal. Failure to do so will cause significant jig saw blade wear. The underside of the workpiece can be greased instead of using a coolant.

Dust extraction

Fig.17: 1. Hose (optional accessory) 2. Dust cover

Insert the hose of the vacuum cleaner into the hole at the rear of the tool.

Lower the dust cover before operation.

NOTE: Dust extraction cannot be performed when making bevel cuts.

Rip fence

Optional accessory

CAUTION: Always be sure that the tool is switched off and the battery cartridge is removed before installing or removing accessories.

Straight cuts

When repeatedly cutting widths of 160 mm or less, use of the rip fence will assure fast, clean, straight cuts.

Fig.18: 1. Rip fence (Guide rule)

Fig.19: 1. Hex wrench 2. Bolt 3. Fence guide 4. Rip fence (Guide rule)

When cutting circles or arcs of 170 mm or less in radius, install the rip fence as follows.

Fig.20: 1. Rip fence (Guide rule)

- Insert the rip fence into the rectangular hole on the side of the base with the fence guide facing up.

- Insert the circular guide pin through either of the two holes on the fence guide. Screw the threaded knob onto the pin to secure the pin.

Fig.21: 1. Threaded knob 2. Fence guide 3. Rip fence (Guide rule) 4. Pin - Slide the rip fence to the desired cutting radius, and tighten the bolt to secure it in place. Then move the base all the way forward.

NOTE: Always use jig saw blades No. B-17, B-18,

B-26 or B-27 when cutting circles or arcs.

Anti-splintering device

Optional accessory, only for aluminum base model

CAUTION: The anti-splintering device cannot be used when making bevel cuts.

Fig.22: 1. Base 2. Anti-splintering device

tool base all the way forward and fit it from the back of tool base.

When you use the cover plate, install the anti-splintering device onto the cover plate.

Cover plate

Optional accessory, only for aluminum base model

Fig.23: 1. Cover plate 2. Base

MAINTENANCE

CAUTION: Always be sure that the tool is switched off and the battery cartridge is removed before attempting to perform inspection or maintenance.

NOTICE: Never use gasoline, benzine, thinner, alcohol or the like. Discoloration, deformation or cracks may result.

To maintain product SAFETY and RELIABILITY, repairs, any other maintenance or adjustment should be performed by Makita Authorized or Factory Service Centers, always using Makita replacement parts.

OPTIONAL ACCESSORIES

CAUTION: These accessories or attachments are recommended for use with your Makita tool specified in this manual. The use of any other accessories or attachments might present a risk ofinjury to persons. Only use accessory or attachment for its stated purpose

If you need any assistance for more details regarding these accessories, ask your local Makita Service Center.

- Jig saw blades

- Hex wrench 3

- Rip fence (guide rule) set

- Anti-splintering device

- Hose (For vacuum cleaner)

- Cover plate

- Makita genuine battery and charger

NOTE: Some items in the list may be included in the tool package as standard accessories. They may differ from country to country.

Makita Europe N.V.

Jan-Baptist Vinkstraat 2, 3070 Kortenberg, Belgium

Makita Corporation

3-11-8, Sumiyoshi-cho, Anjo, Aichi 446-8502 Japan

www.makita.com