Makita HM1213C Demolition Hammer Instruction Manual

makita HM1213C Demolition Hammer

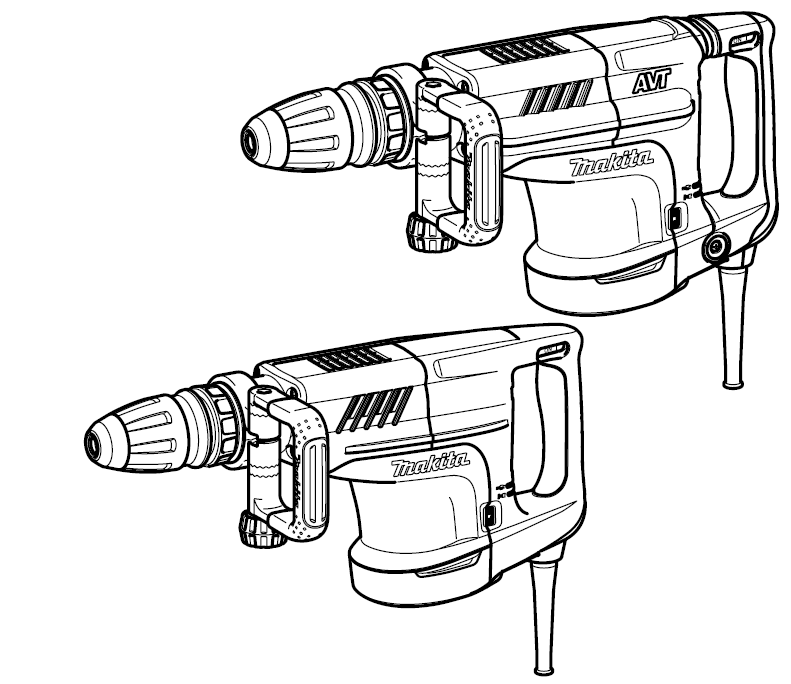

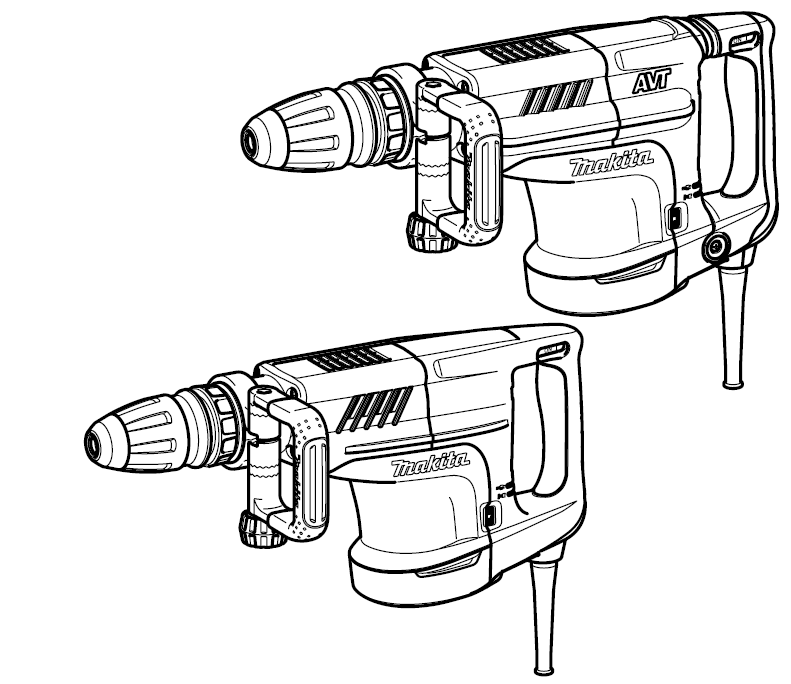

Explanation of general view

- 1- 1. Switch lever

- 2- 1. Adjusting dial

- 3- 1. Power-ON indicator lamp (green)

- 3- 2. Service indicator lamp (red)

- 4- 1. Side handle

- 4- 2. Clamp nut

- 5- 1. Bit shank

- 5- 2. Bit grease

- 6- 1. Releasing cover

- 8- 1. Releasing cover

- 9- 1. Change ring

- 12- 1. Screws

- 13- 1. Connector

- 13-2. White

- 13- 3. Black

- 14- 1. Screwdriver

- 14- 2. Crank cap cover

- 15- 1. Grease

- 16- 1. Connector

- 16-2. White

- 16-3. Black

SPECIFICATIONS

| Model | HM1213C | HM1203C |

| Blows per minute | 950 – 1,900 min-1 | |

| Overall length | 576 mm | |

| Net weight | 10.8 kg | 9.7 kg |

| Safety class | II | |

- Due to our continuing programme of research and development, the specifications herein are subject to change without notice.

- Note: Specifications may differ from country to country.

- Weight according to EPTA-Procedure 01/2003

Intended use

The tool is intended for chiselling work in concrete, brick, stone and asphalt as well as for driving and compacting with appropriate accessories.

Power supply

The tool should be connected only to a power supply of the same voltage as indicated on the nameplate, and can only be operated on single-phase AC supply. They are double-insulated in accordance with European Standard and can, therefore, also be used from sockets without earth wire.

For Model HM1213C

For European countries only

Noise

The typical A-weighted noise level determined according to EN60745:

- Sound pressure level (LpA) : 75 dB(A)

- Sound power level (LWA) : 95 dB(A)

- Uncertainty (K) : 2.5 dB(A)

Wear ear protection

Vibration

The vibration total value (tri-axial vector sum) determined according to EN60745-2-6:

Work mode : chiseling function with side handle Vibration emission (ah,CHeq) : 7.0 m/s2 Uncertainty (K) : 1.5 m/s2

For Model HM1203C

For European countries only Noise

The typical A-weighted noise level determined according to EN60745:

- Sound pressure level (LpA) : 81 dB(A)

- Sound power level (LWA) : 95 dB(A)

- Uncertainty (K) : 2 dB(A)

Wear ear protection

Vibration

The vibration total value (tri-axial vector sum) determined according to EN60745-2-6:

- Work mode : chiseling function with side handle

- Vibration emission (ah,CHeq) : 15.5 m/s2

- Uncertainty (K) : 1.5 m/s2

- The declared vibration emission value has been measured in accordance with the standard test method and may be used for comparing one tool with another.

- The declared vibration emission value may also be used in a preliminary assessment of exposure.

WARNING:

- The vibration emission during actual use of the power tool can differ from the declared emission value depending on the ways in which the tool is used.

- Be sure to identify safety measures to protect the operator that are based on an estimation of exposure in the actual conditions of use (taking account of all parts of the operating cycle such as the times when the tool is switched off and when it is running idle in addition to the trigger time).

EC Declaration of Conformity

We Makita Corporation as the responsible manufacturer declare that the following Makita machine(s):

Designation of Machine: Demolition Hammer

Model No./ Type: HM1213C, HM1203C

are of series production and

Conforms to the following European Directives:

2000/14/EC, 98/37/EC until 28th December 2009 and then with 2006/42/EC from 29th December 2009

And are manufactured in accordance with the following standards or standardised documents:

EN60745

The technical documentation is kept by our authorised representative in Europe who is:

- Makita International Europe Ltd,

- Michigan, Drive, Tongwell,

- Milton Keynes, MK15 8JD, England

The conformity assessment procedure required by Directive 2000/14/EC was in Accordance with annex VIII.

Notified Body:

TUV Rheinland Product Safety GmbH, identification no. 0197

Model HM1213C

Measured Sound Power Level: 95dB

Guaranteed Sound Power Level: 97dB

Model HM1203C

Measured Sound Power Level: 95 dB

Guaranteed Sound Power Level: 98 dB

General Power Tool Safety

Warnings

WARNING Read all safety warnings and all instructions. Failure to follow the warnings and instructions may result in electric shock, fire and/or serious injury.

Save all warnings and instructions for future reference.

SPECIFIC SAFETY RULES

DO NOT let comfort or familiarity with product (gained from repeated use) replace strict adherence to hammer safety rules. If you use this tool unsafely or incorrectly, you can suffer serious personal injury.

- Wear ear protectors. Exposure to noise can cause hearing loss.

- Use auxiliary handle(s), if supplied with the tool. Loss of control can cause personal injury.

- Hold power tools by insulated gripping surfaces, when performing an operation where the cutting accessory may contact hidden wiring or its own cord. Cutting accessory contacting a “live” wire may make exposed metal parts of the tool “live” and could give the operator an electric shock.

- Wear a hard hat (safety helmet), safety glasses and/or face shield. Ordinary eye or sun glasses are NOT safety glasses. It is also highly recommended that you wear a dust mask and thickly padded gloves.

- Be sure the bit is secured in place before operation.

- Under normal operation, the tool is designed to produce vibration. The screws can come loose easily, causing a breakdown or accident. Check tightness of screws carefully before operation.

- In cold weather or when the tool has not been used for a long time, let the tool warm up for a while by operating it under no load. This will loosen up the lubrication. Without proper warm-up, hammering operation is difficult.

- Always be sure you have a firm footing.

Be sure no one is below when using the tool in high locations. - Hold the tool firmly with both hands.

- Keep hands away from moving parts.

- Do not leave the tool running. Operate the tool only when hand-held.

- Do not point the tool at any one in the area when operating. The bit could fly out and injure someone seriously.

- Do not touch the bit or parts close to the bit immediately after operation; they may be extremely hot and could burn your skin.

- Do not operate the tool at no-load unnecessarily.

- Some material contains chemicals which may be toxic. Take caution to prevent dust inhalation and skin contact. Follow material supplier safety data.

WARNING:

MISUSE or failure to follow the safety rules stated in this instruction manual may cause serious personal injury.

FUNCTIONAL DESCRIPTION

CAUTION:

Always be sure that the tool is switched off and unplugged before adjusting or checking function on the tool.

Switch action

Fig.1

CAUTION:

- Before plugging in the tool, always check to see that the tool is switched off.

- Switch can be locked in “ON” position for ease of operator comfort during extended use. Apply caution when locking tool in “ON” position and maintain firm grasp on tool.

To start the tool, push the switch lever “ON (I)” on the left side of the tool. To stop the tool, push the switch lever “OFF (O)” on the right side of the tool.

Speed change

Fig.2

Refer to the table below for the relationship between the number settings on the adjusting dial and the blows per minute.

| Number on adjusting dial | Blows per minute |

| 5 | 1,900 |

| 4 | 1,700 |

| 3 | 1,450 |

| 2 | 1,200 |

| 1 | 950 |

CAUTION:

The speed adjusting dial can be turned only as far as 5 and back to 1. Do not force it past 5 or 1, or the speed adjusting function may no longer work.

For Model HM1213C only

NOTE:

Blows at no load per minute becomes smaller than those on load in order to reduce vibration under no load, but this does not show trouble. Once operation starts with a bit against concrete, blows per minute increase and get to the numbers as shown in the table. When temperature is low and there is less fluidity in grease, the tool may not have this function even with the motor rotating.

Indicator lamp

Fig.3

The green power-ON indicator lamp lights up when the tool is plugged. If the indicator lamp does not light up, the mains cord or the controller may be malfunction. The indicator lamp is lit but the tool does not start even if the tool is switched on, the carbon brushes may be worn out, or the controller, the motor or the ON/OFF switch may be malfunction.

The red service indicator lamp flickers up when the carbon brushes are nearly worn out to indicate that the tool needs servicing. After approx. 8 hours of use, the motor will automatically be shut off.

ASSEMBLY

CAUTION:

Always be sure that the tool is switched off and unplugged before carrying out any work on the tool.

Side handle (auxiliary handle)

Fig.4

Installing or removing the bit

Fig.5

Insert the bit into the tool. Turn the bit and push it in until it engages.

Fig.6

Fig.7

To remove the bit, pull the releasing cover down all the way and pull the bit out.

Fig.8

Fig.9

NOTE:

The change ring cannot turn when the bit is not installed on the tool.

OPERATION

Chipping/Scaling/Demolition

Fig.11

MAINTENANCE

CAUTION:

- Always be sure that the tool is switched off and unplugged before attempting to perform inspection or maintenance.

- Never use gasoline, benzine, thinner, alcohol or the like. Discoloration, deformation or cracks may result.

Lubrication

CAUTION:

This servicing should be performed by Makita Authorized or Factory Service Centers only.

This tool requires no hourly or daily lubrication because it has a grease-packed lubrication system. However, it is recommended to periodically replace the grease for longer tool life.

Run the tool for several minutes to warm it up. Switch off and unplug the tool.

Loosen the six screws and remove the handle. Note that the top screws are different from other screws.

Fig.12

Fig.13

Fig.14

Fig.15

CAUTION:

Be careful not to damage the connector or lead wires especially when wiping out the old grease.

To reassemble the tool, follow the disassembling procedure in reverse.

CAUTION:

Do not tighten the crank cap excessively. It is made of resin and is subject to breakage.

Fig.16

CAUTION:

Be careful not to damage the connector or lead wires especially when installing the handle.

To maintain product SAFETY and RELIABILITY, repairs, carbon brush inspection and replacement, any other maintenance or adjustment should be performed by Makita Authorized Service Centers, always using Makita replacement parts.

ACCESSORIES

CAUTION:

These accessories or attachments are recommended for use with your Makita tool specified in this manual. The use of any other accessories or attachments might present a risk of injury to persons. Only use accessory or attachment for its stated purpose.

If you need any assistance for more details regarding these accessories, ask your local Makita Service Center.

- Bull point(SDS-max)

- Cold chisel(SDS-max)

- Scaling chisel(SDS-max)

- Clay spade(SDS-max)

- Bit grease

- Safety goggles

- Hammer grease

- Plastic carrying case

Makita Corporation

Anjo, Aichi, Japan

www.makita.com