SIEMENS MCP 1500 SINUMERIK ONE User Manual

SIEMENS MCP 1500 SINUMERIK ONE

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are graded according to the degree of danger.

DANGER: indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING: indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION indicates that minor personal injury can result if proper precautions are not taken.

NOTICE: indicates that property damage can result if proper precautions are not taken. If more than one degree of danger is present, the warning notice representing the highest degree of danger will be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to property damage.

Qualified Personnel

The product/system described in this documentation may be operated only by personnel qualified for the specific task in accordance with the relevant documentation, in particular its warning notices and safety instructions. Qualified personnel are those who, based on their training and experience, are capable of identifying risks and avoiding potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following: WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical documentation. If products and components from other manufacturers are used, these must be recommended or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and maintenance are required to ensure that the products operate safely and without any problems. The permissible ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication may

be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the information in this publication is reviewed regularly and any necessary corrections are included in subsequent editions.

Fundamental safety instructions

General safety instructions

WARNING: Electric shock and danger to life due to other energy sources

Touching live components can result in death or severe injury.

- Only work on electrical devices when you are qualified for this job.

- Always observe the country-specific safety rules.

Generally, the following steps apply when establishing safety:

- Prepare for disconnection. Notify all those who will be affected by the procedure.

- Isolate the drive system from the power supply and take measures to prevent it being switched back on again.

- Wait until the discharge time specified on the warning labels has elapsed.

- Check that there is no voltage between any of the power connections, and between any of the power connections and the protective conductor connection.

- Check whether the existing auxiliary supply circuits are de-energized.

- Ensure that the motors cannot move.

- Identify all other dangerous energy sources, e.g. compressed air, hydraulic systems, or water. Switch the energy sources to a safe state.

- Check that the correct drive system is completely locked.

After you have completed the work, restore the operational readiness in the inverse sequence.

WARNING: Electric shock due to connection to an unsuitable power supply

When equipment is connected to an unsuitable power supply, exposed components may carry a hazardous voltage. Contact with hazardous voltage can result in severe injury or death.

- Only use power supplies that provide SELV (Safety Extra Low Voltage) or PELV- (Protective Extra Low Voltage) output voltages for all connections and terminals of the electronics modules.

WARNING: Electric shock due to equipment damage

Improper handling may cause damage to equipment. For damaged devices, hazardous voltages can be present at the enclosure or at exposed components; if touched, this can result in death or severe injury.

- Ensure compliance with the limit values specified in the technical data during transport, storage and operation.

- Do not use any damaged devices.

WARNING: Electric shock due to unconnected cable shields

Hazardous touch voltages can occur through capacitive cross-coupling due to unconnected cable shields.

- As a minimum, connect cable shields and the cores of cables that are not used at one end at the grounded housing potential.

WARNING: Electric shock if there is no ground connection

For missing or incorrectly implemented protective conductor connection for devices with protection class I, high voltages can be present at open, exposed parts, which when touched, can result in death or severe injury.

Ground the device in compliance with the applicable regulations.

NOTICE: Damage to equipment due to unsuitable tightening tools.

Unsuitable tightening tools or fastening methods can damage the screws of the equipment.

- Only use screw inserts that exactly match the screw head.

- Tighten the screws with the torque specified in the technical documentation.

- Use a torque wrench or a mechanical precision nut runner with a dynamic torque sensor and speed limitation system.

- Adjust the tools used regularly.

WARNING: Spread of fire from built-in devices

Built-in devices can cause a fire and a pressure wave in the event of a fault. Fire and smoke can escape from the control cabinet and cause serious personal injury and property damage.

- Install built-in appliances in a robust metal control cabinet that is suitable for protecting people from fire and smoke.

- Only operate built-in devices with the control cabinet doors closed.

- Ensure that smoke can only escape via controlled and monitored paths.

WARNING: Unexpected machine movement caused by radio devices or mobile phones

Using radio devices, cellphones, or mobile WLAN devices in the immediate vicinity of the components can result in equipment malfunction. Malfunctions may impair the functional safety of machines and can therefore put people in danger or lead to property damage.

- Therefore, if you move closer than 20 cm to the components, be sure to switch off radio devices, cellphones or WLAN devices.

- Use the “SIEMENS Industry Online Support app” only on equipment that has already been switched off.

WARNING: Fire due to inadequate ventilation clearances

Inadequate ventilation clearances can cause overheating of components with subsequent fire and smoke. This can cause severe injury or even death. This can also result in increased downtime and reduced service lives for devices/systems.

Ensure compliance with the specified minimum clearance as ventilation clearance for the respective component.

NOTICE: Overheating due to inadmissible mounting position

The device may overheat and therefore be damaged if mounted in an inadmissible position.

Only operate the device in admissible mounting positions.

Equipment damage due to electric fields or electrostatic discharge

WARNING: Unexpected movement of machines caused by inactive safety functions

Inactive or non-adapted safety functions can trigger unexpected machine movements that may result in serious injury or death.

- Observe the information in the appropriate product documentation before commissioning.

- Carry out a safety inspection for functions relevant to safety on the entire system, including all safety-related components.

- Ensure that the safety functions used in your drives and automation tasks are adjusted and activated through appropriate parameterizing.

- Perform a function test.

- Only put your plant into live operation once you have guaranteed that the functions relevant to safety are running correctly.

Note: Important Safety instructions for Safety Integrated

If you want to use Safety Integrated functions, you must observe the Safety instructions in the Safety Integrated documentation.

Electrostatic sensitive devices (ESD) are individual components, integrated circuits, modules or devices that may be damaged by either electric fields or electrostatic discharge.

NOTICE: Equipment damage due to electric fields or electrostatic discharge

Electric fields or electrostatic discharge can cause malfunctions through damaged individual components, integrated circuits, modules or devices.

- Only pack, store, transport and send electronic components, modules or devices in their original packaging or in other suitable materials, e.g conductive foam rubber of aluminum foil.

- Only touch components, modules and devices when you are grounded by one of the following methods:

Wearing an ESD wrist strap

Wearing ESD shoes or ESD grounding straps in ESD areas with conductive flooring - Only place electronic components, modules or devices on conductive surfaces (table with ESD surface, conductive ESD foam, ESD packaging, ESD transport container).

Warranty and liability for application examples

Application examples are not binding and do not claim to be complete regarding configuration, equipment or any eventuality which may arise. Application examples do not represent specific customer solutions, but are only intended to provide support for typical tasks.

As the user you yourself are responsible for ensuring that the products described are operated correctly. Application examples do not relieve you of your responsibility for safe handling when using, installing, operating and maintaining the equipment.

Security information

- Siemens provides products and solutions with industrial security functions that support the secure operation of plants, systems, machines and networks.

- In order to protect plants, systems, machines and networks against cyber threats, it is necessary to implement – and continuously maintain – a holistic, state-of-the-art industrial security concept. Siemens’ products and solutions constitute one element of such a concept.

- Customers are responsible for preventing unauthorized access to their plants, systems, machines and networks. Such systems, machines and components should only be connected to an enterprise network or the internet if and to the extent such a connection is necessary and only when appropriate security measures (e.g. firewalls and/or network segmentation) are in place.

- For additional information on industrial security measures that may be implemented, please visit

https://www.siemens.com/industrialsecurity (https://www.siemens.com/industrialsecurity). - Siemens’ products and solutions undergo continuous development to make them more secure. Siemens strongly recommends that product updates are applied as soon as they are available and that the latest product versions are used. Use of product versions that are no longer supported, and failure to apply the latest updates may increase customer’s exposure to cyber threats.

- To stay informed about product updates, subscribe to the Siemens Industrial Security RSS Feed under

https://www.siemens.com/cert (https://www.siemens.com/cert). - Further information is provided on the Internet:

Residual risks of power drive systems

Industrial Security Configuration Manual (https://support.industry.siemens.com/cs/ww/en/view/108862708)

WARNING: Unsafe operating states resulting from software manipulation

Software manipulations, e.g. viruses, Trojans, or worms, can cause unsafe operating states in your system that may lead to death, serious injury, and property damage.

- Keep the software up to date.

- Incorporate the automation and drive components into a holistic, state-of-the-art industrial security concept for the installation or machine.

- Make sure that you include all installed products into the holistic industrial security concept.

- Protect files stored on exchangeable storage media from malicious software by with suitable protection measures, e.g. virus scanners.

- On completion of commissioning, check all security-related settings.

Residual risks of power drive systems

When assessing the machine- or system-related risk in accordance with the respective local regulations (e.g., EC Machinery Directive), the machine manufacturer or system installer must take into account the following residual risks emanating from the control and drive components of a drive system:

- Unintentional movements of driven machine or system components during commissioning, operation, maintenance, and repairs caused by, for example,

- Hardware and/or software errors in the sensors, control system, actuators, and cables and connections

- Response times of the control system and of the drive

- Operation and/or environmental conditions outside the specification

- Condensation/conductive contamination

- Parameterization, programming, cabling, and installation errors

- Use of wireless devices/mobile phones in the immediate vicinity of electronic components

- External influences/damage

- X-ray, ionizing radiation and cosmic radiation

- Unusually high temperatures, including open flames, as well as emissions of light, noise, particles, gases, etc., can occur inside and outside the components under fault conditions caused by, for example:

- Component failure

- Software errors

- Operation and/or environmental conditions outside the specification

- External influences/damage

- Hazardous shock voltages caused by, for example:

- Component failure

- Influence during electrostatic charging

- Induction of voltages in moving motors

- Operation and/or environmental conditions outside the specification

- Condensation/conductive contamination

- External influences/damage

- Electrical, magnetic and electromagnetic fields generated in operation that can pose a risk to people with a pacemaker, implants or metal replacement joints, etc., if they are too close

- Release of environmental pollutants or emissions as a result of improper operation of the system and/or failure to dispose of components safely and correctly

- Influence of network-connected communication systems, e.g. ripple-control transmitters or data communication via the network

For more information about the residual risks of the drive system components, see the relevant sections in the technical user documentation.

Overview

This manual describes the specific properties of the SINUMERIK ONE MCP 1500 machine control panel. The documentation is always structured in 2 parts. Part 1 contains general information that applies to all machine control panels. Part 2 covers specifics of individual machine control panels. Both parts of the documentation must always be observed.

More information

You can find more information about SINUMERIK ONE MCPs in: SINUMERIK ONE MCP – Part 1: MCP xxxx

Validity

The following description applies to the following component:

| Designation | Article number |

| SINUMERIK ONE MCP 1500 | 6FC5303-0AP01-0AA0 |

View

Dimension drawings

The installation clearance for the MCPs is 70 mm including the wiring portion.

Panel cutout

The MCP 1500 is attached to the rear side of the operator panel using 8 tension jacks (contained in the scope of delivery). The tightening torque is 0.4 Nm.

Operator control and display elements

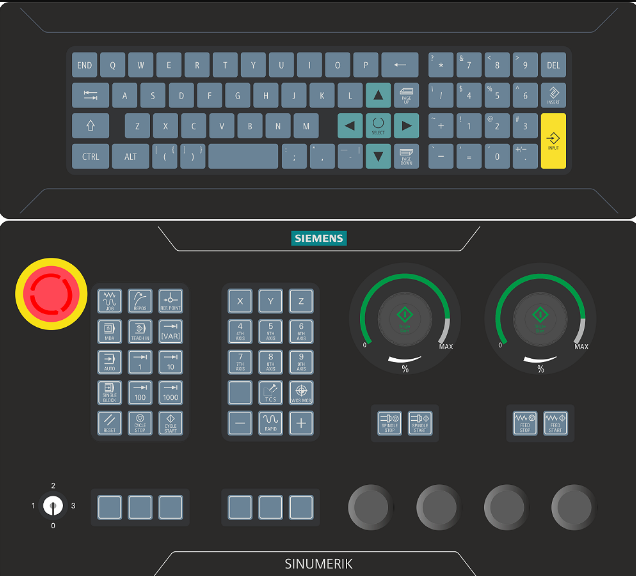

Front side

- Emergency stop

- Keypad 1 (operating mode block)

- Keypad 2 (axis block)

- Powerride 2 (spindle) + keypad 2.2

- Powerride 1 (feed) + keypad 2.1

- 4x mounting space for 22.5 mm element

- Keypad 1.2

- Keypad 1.1

- Key-operated authorization switch

Figure 4-1 Position of operator controls on the MCP 1500

Rear side

- Power supply interface X10

- Switch S2

- Ethernet interfaces X20 port 1/ port 2

- Emergency stop

- Handwheel connections X60/ X61

- Protective conductor connection

- Interface of the customer-specific inputs/outputs X516

- Interface of the customer-specific inputs/outputs X515

- 4x mounting space for 22.5 mm element

Installation of the control panel with 8 clamping elements to the mounting opening provided in the frame Clamping elements are provided in the accessory kit of the device.

Figure 4-2 Rear view of the MCP 1500

Handwheel connecting cable

The handwheel connecting cable is not included in the scope of delivery. You will find the article numbers in Chapter “Spare parts/accessories”.

Configuration

Input image

| Slot 1 | Base |

| Slot 2 | Keypad 1 (operating mode block), keypad 1.1 and keypad 1.2 |

| Slot 3 | Keypad 2 (axis block), keypad 2.1 and keypad 2.2 |

| Slot 4 | Powerride 1 (feed) |

| Slot 5 | Powerride 2 (spindle) |

| Slot 6 | Handwheel 1 |

| Slot 7 | Handwheel 2 |

Output image

| Slot 1 | Base |

| Slot 2 | Keypad 1 (operating mode block), keypad 1.1 and keypad 1.2 |

| Slot 3 | Keypad 2 (axis block), keypad 2.1 and keypad 2.2 |

| Slot 4 | Powerride 1 (feed) |

| Slot 5 | Powerride 2 (spindle) |

Technical data

| MCP 1500 | ||

| Safety | ||

| Safety class according to EN 50178 | III; PELV | |

| Degree of protection according to EN 60529 1) | Front: IP54 | Rear: IP00 2) |

| Approvals | CE / EAC / UL | |

| Flame resistance | UL 94 V-1 3) | |

| UL identifier | MCPS2101-398225E-0402051AA0 | |

| Electrical data | ||

| Overvoltage category | Secondary circuit supplied from primary circuits up to Cat. III (OVC III), 300 V AC4) | |

| Power supply 5) | 24 V DC (20.4 V….. 28.8 V) | |

| Power consumption, max., at 28.8 V | + 10 USB ports | 10x 2.6 W |

| + 2 handwheels | 2x 1 W | |

| +24 V load on X515/X516 | 16x 0.15 A | |

| Total | 115 W | |

| Current consumption, max., at 20.4 V | 4.7 A | |

| Mechanical data | ||

| Dimensions W x H x D (mm) | 398.0 x 225.0 x 70 | |

| Weight (kg) | 2.82 | |

| Perm. vertical mounting positions | 0° – 90° | |

| Tightening torques, max. | M3: 0.5 Nm standard | |

| M4: 1 Nm | ||

| M5: 1.5 Nm standard | ||

| Grounding: 3 Nm, hold bottom nut in place | ||

| Mechan. stability | According to UL 61010 3) | |

| Climatic environmental conditions | ||

| Classification of the climatic environment | 3K3 according to EN 60721‑3-3 | |

| Heat dissipation | By natural convection | |

| Condensation and ice formation | Not permitted | |

| Supply air | Without corrosive gases, dusts and oils | |

| Use and operation | ||

| Max. installation altitude | Up to 1000 m without derating From 1000 m to 4000 m with linear ambient temperature derating, -0.5 K per 100 m | |

| Temperature limit values (storage) | -40 … 70 °C (cyclic) | |

| Temperature limit values (operation) | 0 … 45 °C (front) 0 … 55 °C (rear) | |

| Temperature change | Max. 30 K/h | |

| MCP 1500 | ||

| Relative humidity | 5 … 90% (without condensation) | |

| Permissible change in the relative humid‐ ity | Max. 6%/h | |

| Pollution degree | 2 (only use indoors) | |

| Mechanical environmental conditions | ||

| Classification of the mechanical environ‐ ment | Class 3M2 according to EN 60721-3-3 | |

| Vibration load during operation | Frequency range: 10 – 200 Hz Deflection at 9 – 18 Hz: 1.5 mm Acceleration at 18 – 200 Hz: 2 g | |

| Shock load during operation with shock- sensitive components | Acceleration: 5 g Shock duration: 30 ms |

Acceleration: 15 g Shock duration: 11 ms |

| Load: 3 x in each direction | ||

| EMC conducted / radiation | Class C2 according to EN 61800-3 | |

- The system installer ensures the system is sealed properly according to IP65, IP classification has not been checked by UL, UL TYPE 1.

- Open-type equipment according to UL 61010.

- The customer must ensure that the product, with the rear cover to be attached by the customer, meets the requirements for flame resistance of the material according to UL 94 V-1 and the mechanical stability /fire protection requirements / touch protection according to UL 61010.

- If power supply units with primary-side supplies up to 600 V AC (line-to-neutral voltage) have to be deployed, the transient voltages on the primary side of the power supply unit must be limited to 4000 V.

- Connect the device only to a 24 V DC power supply that is compliant with protective extra-low voltage (PELV) requirements according to UL 61010.

Note: The 24 V DC current source must be adapted to the input data of the device (see “Electrical data”).

Note: In a residential environment, this product can cause high-frequency interference, which may make interference suppression measures necessary.

- Have the installation and commissioning with appropriate radio interference suppression measures performed by qualified personnel.

Note: Damage to components by coolants and lubricants

The SINUMERIK operator components have been designed for industrial use, particularly on machine tools and production machines. This also takes into account the use of commercially available coolants and lubricants. The use of aggressive compounds and additives can damage components and result in their failure.

Avoid contact between the operator components with coolants and lubricants, as resistance to all coolants and lubricants cannot be guaranteed.

Emergency stop button

| Rated voltage | 24 V DC |

| Current rating, max. | 3 A |

| Current rating, min. | 1 mA |

| Switching capacity | DC 13 according to EN 60947-5-1 |

| Conditional rated short-circuit current | 10 A gL/gG according to EN 60947-5-1 |

| B10d | 500000 |

Note

The quantitative assessment of the emergency stop safety function must be based on the B10d values corresponding to the used standards (e.g. ISO 13849-1) under consideration of the respective application (frequency of the actuation, service life, diagnostics by the evaluation unit, etc.). The B10d values only apply when the technical properties of the emergency stop button are taken into account.

Index

M MCP 1500

Emergency stop button, 23

T Technical data, 21

- Current consumption, 21

- Power consumption, 21

ONE MCP Part 2: MCP 1500

Equipment Manual, 05/2022, A5E52027171B AA