Honeywell F74C Reverse Rinsing Filter MC876 Automatic Backwash Controls Installation Guide

Honeywell F74C Reverse Rinsing Filter MC876 Automatic Backwash Controls Installation Guide

APPLICATION

‘The F74C Reverse Rinsing Water Filters, used at point-of-entry (POE) to remove sediment and debris from residential or commercial water systems, ensure a continuous supply of filtered water. The fine filter prevents the ingress of foreign bodies, such as rust particles and grains of sand. The flow, filtering capacity and ease of cleaning make the F74C the ideal filter for the most demanding applications. Both horizontal and vertical installations are possible.

The MV876 Automatic-Backwash Control is available as an accessory. This control is fitted to the drain valve and is programmed by the user to automatically perform the backwash function according to the desired interval.

SPECIFICATIONS

IMPORTANT

The specifications given in this publication do not include normal manufacturing tolerances.

Therefore, units may not exactly match the listed specifications. Also, products are tested and calibrated under closely controlled conditions, and some minor differences in performance can be expected if those conditions are changed.

F74C:

Models:

- Water filters with 100 micron screens and hose connections.

- F74C1015: 3/4 in. sweat and NPT threaded tailpieces.

- F74C1023: 1 in. sweat and NPT threaded tailpieces.

Materials of Construction:

- Body: Engineered plastic.

- Inlet/Outlet Adapter: Bronze.

- Sump: Engineered plastic.

- Screen: Stainless steel.

- Internal Construction: Acetal copolymer.

- Seals: NBR.

- Ball Valve: Brass with PTFE seals.

Inlet Pressure:

- Minimum: 22 psi (with unrestricted backwash discharge).

- Maximum: 232 psi.

- Medium: Water.

- Maximum Operating Temperature: 86°F (30°C).

- Pipe Size: 3/4 in. and 1 in.

- Mounting Position: For vertical or horizontal (filter bowl always downwards).

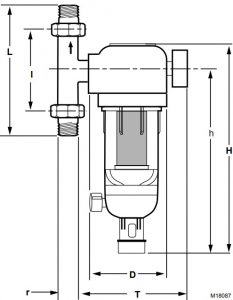

- Dimensions: See Fig. 1 and Table 1.

Dimensions

Fig. 1. Dimension drawing of F74C.

Table 1. Dimensions of F74C in in. (mm).

| Dimension |

Connection Size | |

| 3/4 | 1 | |

| H | 12-13/16 (324) | 12-13/16 (324) |

| h | 11-3/16 (285) | 11-3/16 (285) |

| L | 6-3/8 (162) | 7-1/4 (184) |

| l | 3-9/16 (90) | 3-15/16 (100) |

| D | 4-1/8 (105) | 4-1/8 (105) |

| r | 1-1/16 (27) | 1-1/16 (27) |

| t | 2-5/8 (66) | 2-5/8 (66) |

| T | 5-5/16 (150) | 5-5/16 (150) |

Weight:

- 3/4 in.: 6 lb (2.7 kg).

- 1 in.: 7 lb (3.2 kg).

Operating Pressure Drop Versus Flow:

See Fig. 2.

Maximum recommended: 3 psi to 7 psi (with clean screen).

Fig. 2. F74C Pressure drop vs. flow

Connections: Union on inlet and outlet: External NPTthreaded or sweat. Inlet/outlet assembly can be rotated to fit on vertical or horizontal piping.

Screen Sizes: Shipped with Device: 100 microns.

MV876 Automatic-Backwash Control:

MV876B1018: Bayonet mounted shaft of 24 Vac motor and timer replaces ball valve manual control for automatic backwash at preprogrammed intervals. 24V transformer not included. For use with F74C and F76S Filters only.

Specifications:

- Power: 4 VA.

- Current: 170 mA.

- Voltage: 24 Vac.

- Cycle time: 20 seconds (approximate).

- Timer: Variable. See Table 3

Accessories for F74C:

AF74-1A Replacement filter assembly for F74C, 3/4 in. and 1 in., 100 micron; includes the filter insert complete (O-ring, mesh with mesh support, impeller),

sump O-ring (mounted between the filter housing and the sump).

KF74-1A Replacement sump assembly for the F74C; includes the sump assembly complete (ball valve, plastic air gap adaptor), sump O-ring (mounted between the filter housing and the sump).

- TBD Opaque sump cover for F74C 3/4 in. and 1 in.

- U76S5015 3/4 in. sweat tailpiece.

- U76S5023 1 in. sweat tailpiece.

- U76T1014 3/4 in. NPT tailpiece.

- U76T1022 1 in. NPT tailpiece.

- 901444 Union gasket for F74; 3/4 in., 10 gaskets in package.

- 901445 Union gasket for F74; 1 in., 10 gaskets in package.

- ZR 10 K-34 Double ring wrench for removing filter bowl.

Table 2. Flow Capacity of F74C in Gallons per Minute (gpm)

|

Model |

Size |

Pressure Drop in psi |

Cv | |||||

| 1 | 2 | 3 | 4 | 5 | 15 | |||

| F74C1015 | 3/4 | 9.0 | 12.7 | 15.6 | 18.0 | 20.1 | 34.9 | 9 |

| F74C1023 | 1 | 10.1 | 14.3 | 17.5 | 20.2 | 22.6 | 39.1 | 10.1 |

Table 3. MV876B Timer Selections

Program Value |

Backwash Interval |

| 1 | 4 minutes |

2 |

8 minutes |

3 |

16 minutes |

| 4 | 32 minutes |

5 |

1 hour |

| 6 | 2 hours |

7 |

4 hours |

| 8 | 8 hours |

9 |

17 hours |

| 10 | 34 hours |

11 |

3 days |

| 12 | 6 days |

13 |

11 days |

| 14 | 23 days |

15 |

45 days |

| 16 | 3 months |

Planning the Installation

The F74C should be sized based on the required flow rate and the resulting pressure drop across the filter. As a guideline for most applications, the F74C should be sized for a pressure drop between 3 psi and 7 psi.

EXAMPLE: What size F74C is required to provide a flow rate of 20 gpm? Reading Table 2 at 20 gpm, a 3/4 in. model has 5 psi drop and a 1 in. model has 4 psi drop.

As both models meet the 3 to 7 psi range, the selection should be based on size preference.

An increased pressure drop across the filter results when higher velocities are maintained to increase the capacity through any given size filter. Severe pressure drops will be encountered as capacity approaches that of the pipe size. To ensure the backwash cycle operates properly and cleaning action is not reduced, follow all recommendations in Fig. 3. Refer to Fig. 3a for an ideal installation.

All filter installations are different. The size, type and amount of dirt and debris and the flow rate must always be considered when choosing a screen and deciding to install multiple F74C Water Filters in parallel.

- Fig. 3. Ideal F74C installation. A funnel mounted directly under the backwash port is the best installation layout.

- Fig. 4. Make sure the inlet pipe is not downsized.

- Fig. 5. Make sure the backwash outlet pipe is not downsized, long or crimped. Instead, install a short oversized pipe on the backwash outlet. Do not use a low capacity solenoid valve to automate the backwash cycle.

- Fig. 6. Make sure the backwash outlet is not raised above the F74C. If the backwash outlet must be raised above the F74C, increase the inlet pressure 5 psi for every 10 feet that it is raised.

- Fig. 7. Make sure the F74C is not used with an undersized pump. An undersized pump may not provide proper pressure or flow.

- Fig. 8. Make sure the F74C is not installed in a bypass across a pump.

INSTALLATION

When Installing this product…

- Read these instructions carefully. Failure to follow them could damage the product or cause a hazardous condition.

- Check ratings given in these instructions and on the product to make sure the product is suitable for your application.

- Make sure the installer is a trained, experienced service technician.

- Use these instructions to check out product operation after installation.

- Equipment Damage Hazard. Excessive pressure or temperature can damage the device.

- Make sure water temperature and pressure are below maximum ratings specified.

- Equipment Damage Hazard.

- Excessive heat can damage internal parts.

- Before sweat soldering, separate the tailpieces and nuts from the inlet/outlet adapter.

F74C Installation.

When installing an F74C, use the following procedure:

- Shut off water supply by closing the water supply valve.

- Install inlet/outlet adapter so that filter is vertical.

- Install the F74C in the water line with the arrow pointing in the direction of water flow.

IMPORTANT

When using an MV876, stop here and install the MV876. - Open a downstream tap.

- Slowly open the water supply valve.

- Once the F74C sump fills with water, close the downstream tap and fully open the water supply valve.

MV876 Installation

- Open the backwash outlet ball valve.

Remove the backwash outlet handle. - Install the MV876. See Fig. 9 and 10.

- When you rotate the MV876 on installation, it closes the backwash outlet ball valve.

- Connect the MV876 to a 24 Vac power supply. See fig. 14.

- Open a downstream tap.

- Slowly open the water supply valve.

- Once the F74C sump fills with water, close the downstream tap and fully open the water supplyvalve.

- Program the desired backwash interval by pushing the program button until the desired interval number appears in the display.

Fig. 9. Installing the MV876.

Fig. 10. Final position of MV876 and F74C

As the F74C operates, screens become plugged.

Backwash the F74C when the pressure gauge measures about five psi lower than when first installed. However, each installation is different. Residential applications can require backwash only once a week, or once every few weeks .

For residential applications, backwashing the F74C oncea week, regardless of need, is an excellent guideline to follow to ensure F74C peak operating efficiency.

Fitting Batteries and Fuses

The batteries (not included) provide power to the MV876 in the event of a power loss. This is desirable, especially when power loss occurs during the reverse rinsing cycle. to provide this, the MV876 requires four AA alkaline batteries. Install these batteries in the cover of the MV876 as follows:

- Electrical Shock or Equipment Damage Hazard.

- Can shock individuals or short equipment circuitry.

- Disconnect power supply before installing the batteries or fuses.

- Unscrew the four housing screws and set them aside. See Figure 11.

IMPORTANT

Make sure the connecting cable is protected from damage when the MV876 cover is removed. - Remove the MV876 cover. See Fig. 11.

- Insert four AA alkaline batteries. See Fig. 12.

- Replace the cover.

- Replace and tighten the four housing screws.

- To avoid unnecessary battery drainage, connect the MV876 to power as soon as possible after inserting new batteries.

- To ensure the availability of battery power, replace the batteries after a power loss.

If the 800 mA fuse blows, replace it as follows:

- Electrical Shock or Equipment Damage Hazard.

- Can shock individuals or short equipment circuitry.

- Disconnect power supply before installing the batteries or fuses.

- Unscrew the four housing screws and set them aside (see Fig. 11).

IMPORTANT make sure that the connecting cable is protected from damage while the MV876 cover is removed. - Remove the MV876 cover.

- Remove and discard the old fuse (see Fig. 13).

- Insert a new 800 mA fuse.

- Replace the cover.

- Replace and tighten the four housing screws.

- Reconnect the power supply.

Fig. 11. Removing the MV876 cover

Fig. 12. Installing batteries in the MV876.

Fig. 13. Replacing the MV876 fuse.

WIRING

- Electrical Shock or Equipment Damage Hazard.

- Can shock individuals or short equipment circuitry.

- Disconnect power supply before wiring.

IMPORTANT

All wiring must comply with applicable codes and ordinances.

MV876

- Mount the 24 Vac transformer and wire as shown in Fig. 14.

- Reconnect power to the system. When the system is powered, the MV876 will run through one backwash cycle (approximately 20 seconds).

- Set MV876 backwash interval to the desired setting. See the Operation section.

- Check MV876 operation by interrupting primary power to the transformer. When power is switched back on, the MV876 will backwash the F74C once.

F74C REPLACEMENT PARTS LIST (SEE FIG. 15)

Table 4. Parts and Accessories for F74C

|

Part Number |

Letter in Fig. 15 |

Description |

Contents |

| U76S5051 | A | 3/4 in. sweat tailpiece | Tailpiece |

| U76S5023 | A | 1 in. sweat tailpiece | Tailpiece |

| U76T1014 | B | 3/4 in. NPT tailpiece | Tailpiece |

| U76T1022 | B | 1 in. NPT tailpiece | Tailpiece |

| 901444 | C | Union gasket, 3/4 in. | 10 gaskets in package |

| 901445 | C | Union gasket, 1 in. | 10 gaskets in package |

| AF74-1A | D | Replacement filter assembly for F74C, 3/4 in. and 1 in., 100 micron. | Includes the filter insert complete (O-ring, mesh with mesh support, impeller), sump O-ring (mounted between the filter housing and the sump). |

| KF74-1A | E | Replacement sump assembly for F74C | Includes the sump assembly complete (ball valve, plastic air gap adaptor), sump O-ring (mounted between the filter housing and the sump). |

Fig. 15. F74C Exploded View. parts are keyed to F74C Replacement parts List.

Customer Support

Home and Building Control

Honeywell

1985 Douglas Drive North

Golden Valley, MN 55422

Home and Building Control

Honeywell Limited-Honeywell Limitée

35 Dynamic Drive

Scarborough, Ontario

M1V 4Z9

Web: http://www.honeywell.com/