Honeywell Fillmatic Pressure Reducing Valve Installation Guide

This is a legacy product document supported by Resideo. It is no longer manufactured

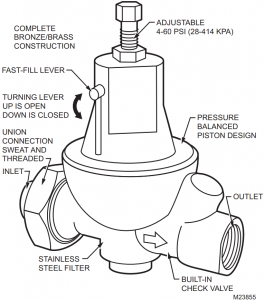

Fillmatic™ Pressure Reducing Valve

FM450, FM462RP (REPLACES FM451)

INSTALLATION INSTRUCTIONS

APPLICATIONS

Pressure reducing valve for automatic control of hot water boiler make up and other pressure reducing applications.

FEATURES

- Good for 12 story building.

- Adjustable 4-60 psi (28-414 kPa).

- Fast-fill feature.

- Built-in check valve.

- Stainless steel filter.

- Pressure balanced piston design.

- Union connection sweat and threaded.

- Complete bronze/brass construction.

SPECIFICATIONS

Maximum Temperature Continuous Operation: 180 °F (82 °C).

Adjustment Range: 4-60 psi (28-414 kPa).

Factory Pressure Setting: 12 psi (83 kPa).

Maximum Temperature: 212 °F (100 °C).

Maximum Pressure: 150 psi (1034 kPa).

Minimum Water Temperature: 40 °F (4 °C).

Dimensions: See Table1.

Table 1. Dimensions.

| Product Number | Inlet Connection | Body | Outlet Connection | Dimension L x H in inches (mm) | Weight in lbs (kg) |

| FM450 | 1/2 in. sweat or threaded union option | Brass | 1/2 in. NPT | 4-1/8 x 5-5/16 (105 x 135) | 2.00 (0.9) |

| FM462RP | Filter Assembly | 0.20 (0.1) | |||

INSTALLATION

Install the Pressure Reducing Valve (PRV) with the flow arrow on the body pointing in the direction of flow. A shut-off valve should be installed on the city water side on the PRV.

OPERATION

Fast Fill

- Put the “Fast Fill” lever in the horizontal position.

- When the system has been filled, put the lever in the vertical position.

The fast fill lever must never be left in the horizontal position after the system has been filled. The lever must be placed in the vertical position to avoid over-pressurization and unnecessary relief valve discharge.

Adjustment

The Fillmatic™ valve is factory set for 12 psi (83 kPa). To change this setting, loosen the jam nut. Then turn the hex head adjusting screw clockwise to increase the set pressure or counterclockwise to lower the set pressure. When the desired pressure is obtained, tighten the jam nut while holding the adjusting screw stationary.

Before attempting to adjust the set pressure, make sure the city water pressure is at least 5 psi (34 kPa) higher than the desired set pressure.

Service

If the Fillmatic valve fails to maintain the set cold fill pressure, the filter may be clogged. To service the filter, shut off the city water and the electricity to the boiler control. Drain water from the boiler until boiler pressure is zero. Make sure shut-off valve (knurled knob) on bottom of the Fillmatic valve is fully open, the latest models do not have the shut-off feature. Remove the filter/shut-off valve assembly by turning the hex nut just above the knurled knob. Remove and clean or replace filter. Replace filter/shut-off valve assembly. Turn on city water to refill boiler valve pressure setting. Turn on electricity to boiler to restore normal system operation.

Automation and Control Solutions

Honeywell International Inc. Honeywell Limited-Honeywell Limitée

1985 Douglas Drive North 35 Dynamic Drive

Golden Valley, MN 55422 Toronto, Ontario M1V 4Z9

customer.honeywell.com

® U.S. Registered Trademark

© 2007 Honeywell International Inc.

62-3087 J.I. 04-07