Honeywell TARS-IMU Sensors for Vehicle Implement Control User Manual

Honeywell TARS-IMU Sensors for Vehicle Implement Control User Manual

TARS-IMU Sensors for Vehicle Implement Control

Background

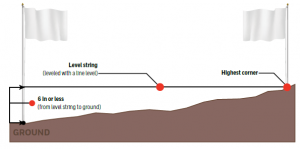

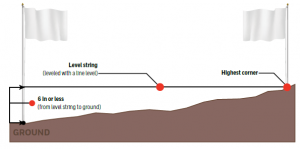

In the past, blades or buckets integral to the front of a dozer, crawler, grader, or wheeled loader relied on the expertise of the equipment operator for grade leveling. As the blade of the equipment engages the grade, the equipment operator adjusts the blade to achieve the desired results of

a specified grade. As the grade is being prepared, the site may require a survey which adds additional time and cost.

Currently, customers need to stake out the site using a laser transit to mark the stakes to properly prepare the ground site. This can be time consuming and is only as precise and accurate as the number of stakes placed in

the ground and measured. Another method to measuring grade is with a Zip level; this is also a slow process that requires the operator to exit the machine in order to check the grade

Figure 1. Grade Measuring

Solution

The Honeywell Transportation Attitude Reference System, or TARS- IMU, is a packaged sensor array designed to report vehicle angular rate, acceleration, and attitude data for demanding applications in industries such as heavy-duty, off-highway transportation.

TARS-IMU enables autonomous vehicle characteristics and enhances efficiency and productivity by reporting key data required to automate and monitor movements of vehicle systems and components. The sensor fusion algorithm can be customized for specific vehicle applications through on-board firmware, allowing movement data to be filtered for extraneous environment and vehicle movements

Features and Benefits

- Enhanced performance from IMU offers reporting of vehicle angular rate, acceleration and inclination (6 degrees of freedom)

- Ruggedized PBT thermoplastic housing design enables it to be used in many demanding applications and environments (IP67- and IP69K-certified)

- Advanced filtering of raw sensor data to minimize unwanted noise and vibrations, improving positioning accuracy

- Optional metal guard for added protection

- Supports 5 V and 9 V to 36 V vehicle power systems

- Operating temperature of -40°C to 85°C [-40°F to 185°F]

- Reduced power consumption

- Small form factor

Figure 1. TARS Six Degrees of Freedom

The Honeywell TARS-IMU sensor array can be programmed to communicate with the operator and/or the control system for a pre- determined set of values.

With equipment containing more electronic capabilities, the TARS-IMU could be integrated into the ECU (Equipment Control Unit) system. In the example with the equipment in operation, the TARS-IMU sensor processes the information and provides real-time feedback for any adjustments to the blade position to achieve the desired grade (see Figure 3).

The Honeywell TARS-IMU has grade measurement capability engineered into its design. Internal machine systems provide real-time grade data to the operator who can adjust the equipment as needed.

This feature enables the end user (as the operator) to prepare a work site more quickly – saving time and money minimizing the need for additional expensive ground surveying equipment.

The TARS sensor provides vehicle motion and movement data that enables the end user to confirm if the job site is as per specification, allowing customers to minimize rework and use of secondary monitoring and measurement equipment.

This assistance will be found more often as the industry moves toward select fully autonomous systems. TARS-IMU ican be a key piece in providing and reporting key machinery and implement data. With six degrees of freedom (see Figure 2), TARS-IMU reports the key movement data such as angular rate, acceleration, and inclination. Furthermore, the TARS-IMU is equipped with customizable data filters; it can be tuned to reduce extraneous noise and vibration that would otherwise distort the valuable data.

The TARS-IMU utilizes a robust packaging design (IP67/IP69K) that makes it more resilient to the rigors of the construction industry. In addition, a wide operating temperature range of 40 °C to 85 °C makes it ready for use in many demanding tool and implement applications.

Figure 3. Honeywell TARS-IMU in a Vehicle Implement Control Application

- Consult with local safety agencies and their requirements when designing a machine control link, interface and all control elements that affect safety.

- Strictly adhere to all installation instructions. Failure to comply with these instructions could result in death or serious injury.

Warranty/Remedy

Honeywell warrants goods of its manufacture as being free of defective materials and faulty workmanship. Honeywell’s standard product warranty applies unless agreed to otherwise by Honeywell in writing; please refer to your order acknowledgement or consult your local sales office for specific warranty details. If warranted goods are returned to Honeywell during the period of coverage, Honeywell will repair or replace, at its option, without charge those items that Honeywell, in its sole discretion, finds defective. The foregoing is buyer’s sole remedy and is in lieu of all other warranties, expressed or implied, including those of merchantability and fitness for a particular purpose. In no event shall Honeywell be liable for consequential, special, or indirect damages.

While Honeywell may provide application assistance personally, through our literature and the Honeywell website, it is customer’s sole responsibility to determine the suitability of the product in the application.

Specifications may change without notice. The information we supply is believed to be accurate and reliable as of this printing. However, Honeywell assumes no responsibility for its use.

For more information

To learn more about Honeywell’s sensing and switching products, call 1-800-537-6945, visit sps.honeywell.com/ast, or email inquiries to

Honeywell Advanced Sensing Technologies

830 East Arapaho Road

Richardson, TX 75081

sps.honeywell.com/ast