Honeywell AMR Ring Magnet Sensor IC Instructions

AMR Ring Magnet Sensor IC

Jitter Test Performance Results

A Technical Note

Introduction

Jitter is defined as the deviation from the true switch point of a sensor. Low jitter performance is critical for many ring magnet speed sensor applications, including wheel speed, transmission, and encoder sensing.

Multiple sensing technologies, such as AMR (anisotropic magnetoresistive) operating in non-saturation mode, GMR (giant magnetoresistive), and differential Hall effect have been used in ring magnet speed sensor applications. In general, the jitter performance of these sensors varies with the size of the airgap. Honeywell has developed a new AMR sensor IC which operates in saturation mode, enabling extremely low jitter across the entire usable airgap range.

Ring Magnet Speed Sensor Jitter Evaluation

Random samples from the four products shown in Table 1 were chosen for this jitter evaluation test.

Table 1. Test Products

| Product | Technology |

| Honeywell VM721V1 | AMR operating in saturation mode |

| Competitor 1 | AMR operating in a non-saturation mode |

| Competitor 2 | GMR |

| Competitor 3 | Differential Hall effect |

Explanation of Saturation Mode

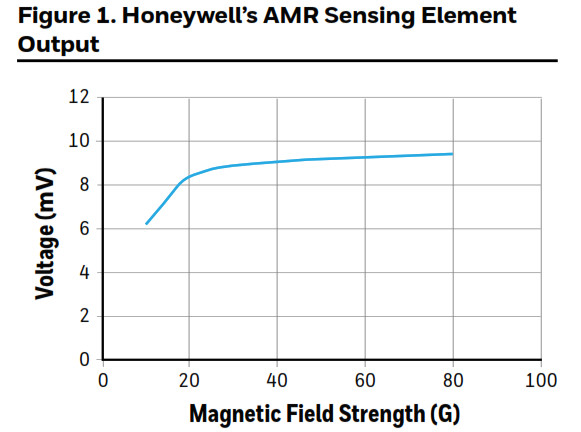

As with most magnetic sensors, the signal decreases as the airgap between the sensor and the target decreases. For AMR sensors, once the sensor is in saturation mode, the magnetic field strength changes very little versus the airgap size. Figure 1 shows that once the field strength reaches 30 Gauss, the output of the AMR sensor in saturation mode shows very little change as the field strength increases to higher Gauss levels. It is this stability in the output signal that allows the AMR sensor in saturation mode to operate with similar characteristics over a wide airgap range.

Test Configuration Setup

A circular target with 32 magnetic pole pairs was used to trigger the product samples. The target was rotated at 2500 RPM. Testing was performed at 25ºC and 150ºC, with an airgap range of 0,5 mm to 4,5 mm which provided a minimum field strength of 10 Gauss.

The test products were mounted on the outside of the ring magnet target. The Honeywell VM721V1 was mounted with the end of the IC toward the ring magnet, while the competitor product samples were mounted with the face of the IC toward the ring magnet target, as per the mounting instructions for each sample. (See Figure 2.)

Figure 2. Sensor Mounting Orientation

Figure 3. Example Oscilloscope Plot from Testing Performed

Results (See Figures 4a and 4b)

The Honeywell VM721V1 AMR sensor operating in saturation mode had jitter of around 1 s over the usable airgap of 0,5 mm to 4,5 mm at both 25ºC and 150ºC.

Although the jitter of Competitor 1’s AMR sensor operating in nonsaturated mode was relatively consistent versus the airgap, the jitter was higher than the VM721V1 and it increased at greater airgaps at 25ºC.

Competitor 2’s GMR sensor had low jitter at the larger airgaps; however, the jitter was significantly higher at the smaller airgaps.

Competitor 3’s differential Hall-effect sensor had higher jitter than the VM721V1 at smaller airgaps, and the jitter increased steadily as the airgap distance increased.

Figure 4a. Jitter Versus Airgap Distance at 25ºC

Figure 4b. Jitter Versus Airgap Distance at 150ºC

Summary

Honeywell AMR sensors’ reduced jitter allows for more accurate feedback for improving system control. The VM721V1 provides a superior airgap performance ranging from 0,5 mm to 4,5 mm, which enables significant implementation advantages compared to other technologies, such as AMR operating in non-saturation mode, GMR, and differential Hall effect.

Warranty/Remedy

Honeywell warrants goods of its manufacture as being free of defective materials and faulty workmanship during the applicable warranty period. Honeywell’s standard product warranty applies unless agreed to otherwise by Honeywell in writing; please refer to your order acknowledgment or consult your local sales office for specific warranty details. If warranted goods are returned to Honeywell during the period of coverage, Honeywell will repair or replace, at its option, without charge those items that Honeywell, in its sole discretion, finds defective. The foregoing is buyer’s sole remedy and is in lieu of all other warranties, expressed or implied, including those of merchantability and fitness for a particular purpose. In no event shall Honeywell be liable for consequential, special, or indirect damages.

While Honeywell may provide application assistance personally, through our literature and the Honeywell website, it is the buyer’s sole responsibility to determine the suitability of the product in the application.

Specifications may change without notice. The information we supply is believed to be accurate and reliable as of this writing. However, Honeywell assumes no responsibility for its use.

For more information

Honeywell Advanced Sensing Technologies services its customers through a worldwide network of sales offices and distributors. For application assistance, current specifications, pricing or the nearest Authorized Distributor, visit sps.honeywell.com/ast or call:

Asia Pacific +65 6355-2828

Europe +44 (0) 1698 481481

USA/Canada +1-800-537-6945

Honeywell Advanced Sensing Technologies

830 East Arapaho Road

Richardson, TX 75081

sps.honeywell.com/ast

005994-2-EN | 2 | 05/21 © 2021

Honeywell International Inc.