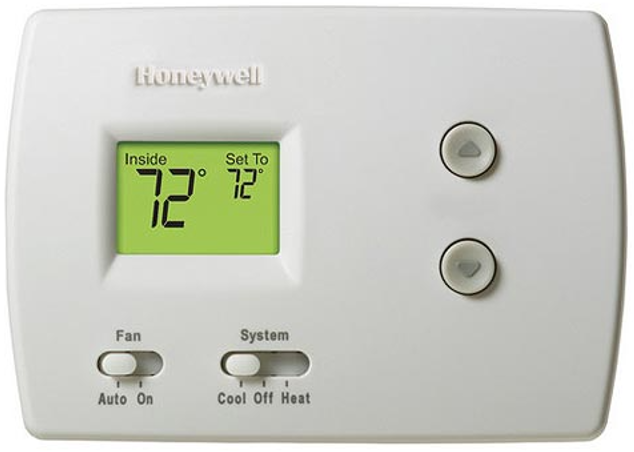

Honeywell Non-programmable Digital Thermostat PRO TH3110D Installation Guide

Installation

Guide

Non-programmable Digital Thermostat

Product Application

This thermostat provides electronic control of 24 VAC single-stage heating and cooling systems, or 750 mV heating systems.

System Types

- Gas, oil, or electric heat with air conditioning

- Warm air, hot water, high-efficiency furnaces, heat pumps, steam, gravity

- Heat only

- Heat only with fan

- Cool only

- 750 mV heating systems

Power Type

- Battery power

- Common wire

- Common wire with battery backup

System Settings

- Heat, Off, Cool

Fan Settings

- Auto, On

Must be installed by a trained, experienced technician

- Read these instructions carefully. Failure to follow these instructions can damage the product or cause a hazardous condition.

- Check the ratings in this booklet to verify that this product is suitable for your application (see page 12).

- Always test for proper operation after installation (see pages 8-9).

Can cause electrical shock or equipment damage. Disconnect power before beginning installation.

If this product is replacing a control that contains mercury in a sealed tube, do not place the old control in the trash. Contact your local waste management authority for instructions regarding recycling and proper disposal.

Installation tips

Install the thermostat about 5 feet (1.5m) above the floor in an area with good air circulation at an average temperature.

Do not install in locations where the thermostat can be affected by:

- Drafts or dead spots behind doors and in corners

- Hot or cold air from ducts

- Sunlight or radiant heat from appliances

- Concealed pipes or chimneys

- Unheated/uncooled areas such as an outside wall behind the thermostat

Pre-installation checklist

Package contents

Check to make sure your package includes the following items:

- PRO TH3110D digital thermostat (wallplate attached to the back)

- Operating manual

- Wall anchors and mounting screws (2 each)

- AA alkaline batteries (2)

Required tools & supplies

- No. 2 Phillips screwdriver

- Small pocket screwdriver

- Drill

- Drill bit (3/16” for drywall, 7/32” for plaster)

- Hammer

- Pencil

- Electrical tape

- Level (optional)

Wallplate installation

Grasp top and bottom of wallplate and pull to remove from the thermostat.

Remove the wallplate from the thermostat as shown at left, then follow directions below for mounting.

- Pull wires through wire holes.

- Position wallplate on wall, level, and mark hole positions with a pencil.

- Drill holes at marked positions as shown below, then tap in supplied wall anchors.

- Place wallplate over anchors, insert and tighten mounting screws.

Wiring

Disconnect power before wiring.

NOTES

R & Rc terminals

In a single-transformer system, leave the metal jumper in place between R & Rc. Remove metal jumper if two-transformer system.

Heat pump systems

If wiring to a heat pump, use a small piece of wire (not supplied) to connect terminals W and Y.

C terminal

The C (common wire) terminal is optional when the thermostat is powered by batteries.

Wire specifications

Use 18- to 22-gauge thermostat wire.

A shielded cable is not required.

Wiring

- Loosen screw terminals, insert wires into the terminal block, then re-tighten screws.

- Push excess wire back into the wall opening. Keep wires in shaded the area as shown at left.

- Plug the wall opening with non-flammable insulation to prevent drafts from affecting thermostat operation.

Terminal Designations

W Heat relay.

Y Compressor contactor.

G Fan relay.

O Heat pump changeover valve energized in cooling.

Rc Cooling power. Connect to the secondary side of the cooling system transformer.

R Heating power. Connect to the secondary side of the heating system transformer.

B Heat pump changeover valve ener- gized in heating.

C Common wire from the secondary side of cooling system transformer.

Wiring diagrams

- Power supply. Provide disconnect means and overload protection as required.

- Factory-installed jumper. Remove for 2-transformer systems only.

- Use either O or B terminals for the changeover valve.

- Use a small piece of wire (not supplied) to connect W and Y terminals.

- Set fan operation switch to Heat Pump (see page 6) and configure for heat pump (see pg. 8).

- Optional 24 VAC common connection.

Fan operation settings

- Gas or Oil: For gas or oil heating systems, leave the fan operation switch in this factory-set position (This setting is for systems that control the fan in a call for heat.)

- Electric or Heat Pump: Change the switch to this setting for heat pump or electric heat systems. (This setting is for systems that

allow the thermostat to control the fan in a call for heat, if a fan wire is connected to the G terminal.)

Power options & mounting

AC Power

The thermostat can be powered by 24 VAC power, or by batteries.

To wire the thermostat for AC power, connect the common side of the cooling transformer to the “C” terminal as shown on the left.

Important: Remove R/Rc jumper for 2-transformer systems only. (See wiring diagram on page 5.)

Battery Power

The thermostat can be powered by batteries alone or, if used with AC power, can provide backup power to the display during power interruptions.

To Mount Thermostat

Align the 4 tabs on the wallplate with corresponding slots on the back of the thermostat, then push gently until the thermostat snaps in place.

Installer setup

Follow the procedure below to configure the thermostat to match the installed heating/cooling system, and customize feature operation as desired.

| Setup Function | Settings & Options |

| 1 System type 5 Heating cycle rate (CPH: cycles/hour) 9 Compressor cycle rate (CPH) 14 Temperature display 15 Compressor protection |

0 Gas, oil, or electric heat with air conditioning 1 Heat pump (5-minute compressor off time in heating and cooling) 5 For gas or oil furnaces of less than 90% efficiency 1 For steam or gravity systems 3 For hot water systems & furnaces of over 90% efficiency 9 For electric furnaces [Other cycle rate options: 2, 4, 6, 7, 8, 10, 11 or 12 CPH] 3 Recommended for most compressors [Other cycle rate options: 1, 2, 4, 5 or 6 CPH] 0 Fahrenheit 1 Celsius 5 Five-minute compressor off time **See page 10 [Other options: 0, 1, 2, 3 or 4-minute off time] |

Installer system test

After completing the installer setup above, press the

Installer system test

Follow the procedure below to test the heating and cooling system.

- Set SYSTEM switch to Cool.

- Press

- Press

- Set SYSTEM switch to Heat.

- Press

- Press

- [Optional] Set SYSTEM switch to Off to display thermostat information (see table, below).

Press - Press

| System Test | System Status |

| 10 Heating system 30 Cooling system 70 Thermostat information (for reference only) |

0 Heat and fan turn off. 1 Heat turns on. Fan also turns on immediately if Fan Operation The switch is set to Electric Heat/Heat Pump (see page 6). 0 Compressor and fan turn off. 1 Compressor and fan turn on. 71 Software revision number (major revisions) 72 Software revision number (minor revisions) 73 Configuration identification code (major) 74 Configuration identification code (minor) 75 Production configuration date code (week) 76 Production configuration date code (year) |

Compressor protection (minimum off time) is bypassed during testing. To prevent equipment damage, avoid cycling the compressor quickly.

A quick reference to controls

A quick reference to display screen

Built-in compressor protection (Setup Function 15)

This feature helps prevent damage to the compressor in the air conditioning or heat pump system.

Damage can occur if the compressor is restarted too soon after shutdown. This feature forces the compressor to wait for a few minutes before restarting.

During the wait time, the message Cool On (or Heat On if you have a heat pump) will flash on the display. When the safe wait time has elapsed, the message stops flashing and the compressor turns on.

In case of difficulty

If you have difficulty with your thermostat, please try the suggestions below. Most problems can be corrected quickly and easily.

| Display is blank | •Check the circuit breaker and reset if necessary. •Make sure heating & cooling power switches are on. •Make sure the equipment door is securely closed. •If battery-powered, make sure fresh AA alkaline batteries are installed. |

| Temperature settings do not change | Make sure heating and cooling temperatures are set to acceptable ranges: •Heat: 40° to 90°F (4.5° to 32°C). •Cool: 50° to 99°F (10° to 37°C). |

| The heating system does not respond (“Heat On” appears on screen) | •Check for 24 Vac at the equipment on the secondary side of the transformer between power and common. If voltage is not present, check the heating equipment to find the cause of the problem. •Check for 24 Vac between the heat terminal (W) and the transformer common. If 24 Vac is present, the thermostat is functional. Check the heating equipment to find the cause of the problem. •Check for loose or broken wires between the thermostat and the heating equipment. |

| The cooling system does not respond (“Cool On” appears on screen) | •Check for 24 Vac at the equipment on the secondary side of the transformer between power and common. If voltage is not present, check the cooling equipment to find the cause of the problem •Check for 24 Vac between the cooling terminal (Y) and the transformer common. If 24 Vac is present, the thermostat is functional. Check the cooling system to find the cause of the problem. •Check for loose or broken wires between the thermostat and the cooling equipment. |

| The fan does not turn on in a call for heat | •Make sure the Fan Operation switch is set to the proper system. |

| “Cool On” or “Heat On” is flashing |

•Compressor protection timeout is engaged. Wait 5 minutes for the system to restart safely, without damage to the compressor. |

| “Heat On” is not displayed | •Set the System switch to Heat and set the temperature level above the current room temperature. |

| “Cool On” is not displayed | •Set the System switch to Cool and set the temperature level below the current room temperature. |

Accessories

Please contact your distributor to order accessories.

Cover plate assembly ……………………………………..Part Number 50002883-001

(Used to cover marks left by old thermostats.)

Specifications

Temperature Ranges

- Heat: 40° to 90°F (4.5° to 32°C)

- Cool: 50° to 99°F (10° to 37°C)

Operating Ambient Temperature

- 32° to 120°F (0° to 48.9°C)

Shipping Temperature

- -20° to 120°F (-28.9° to 48.9°C)

Operating Relative Humidity - 5% to 90% (non-condensing)

Physical Dimensions

- 3-13/16” H x 5-3/8” W x 1-1/4” D

- 97 mm H x 137 mm W x 32 mm D

Electrical Ratings

| Cooling | Voltage (50/60Hz) | Running Current |

| Heating | 20-30 Vac | 0.02-1.0 A |

| (Powerpile) | 750 mV DC | 100 mA DC |

| Cooling | 20-30 Vac | 0.02-1.0 A |

Automation and Control Solutions

Honeywell International Inc.

1985 Douglas Drive North

Golden Valley, MN 55422

http://yourhome.honeywell.com

Honeywell Limited-Honeywell Limitée

35 Dynamic Drive

Scarborough, Ontario M1V 4Z9

® U.S. Registered Trademark.

© 2005 Honeywell International Inc.

Patents pending. All rights reserved.

69-1846 • 06-2005