Makita DDA460 Cordless Angle Drill Instruction Manual

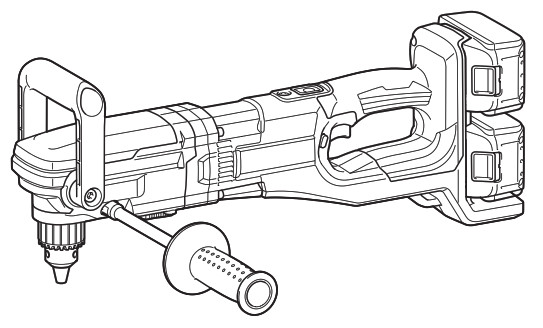

Cordless Angle Drill DDA460

INSTRUCTION MANUAL

SPECIFICATIONS

| Model: | DDA460 | ||

| Gear speed | High | Low | |

| Drilling capacities | Steel | 13 mm | |

| Wood | Auger bit: 50 mm Self-feed bit: 65 mm Hole saw: 105 mm |

Auger bit: 50 mm Self-feed bit: 118 mm Hole saw: 159 mm | |

| No load speed | 0 – 1400 min” | 0 – 350 min” | |

| Overall length *With the front handle extended |

538 mm * 608 mm | ||

| Rated voltage | D.C. 36 V | ||

| Net weight | 5.7 – 6.4 kg | ||

- Due to our continuing program of research and development, the specifications herein are subject to change without notice.

- Specifications may differ from country to country.

- The weight may differ depending on the attachment(s), including the battery cartridge. The lightest and heaviest combinations, according to EPTA-Procedure 01/2014, are shown in the table.

Applicable battery cartridge

BL1815N / BL1820 / BL1820B / BL1830 / BL1830B / BL1840 / BL1840B / BL1850 / BL1850B / BL1860B

- Some of the battery cartridges listed above may not be available depending on your region of residence.

Symbols

| Read the instruction manual. | |

| Only for EU countries Do not dispose of electric equipment or battery packs together with household waste material! In observance of the European Directives, on Waste Electric and Electronic Equipment and Batteries and Accumulators and Waste Batteries and Accumulators and their implementation in accordance with national laws, electric equipment, and batteries and battery pack(s) that have reached the end of their life must be collected separately and returned to an environmentally compatible recycling facility. |

Intended use

The tool is intended for drilling in wood, metal, and plastic.

Noise

The typical A-weighted noise level determined according to EN60745:

Sound pressure level (LpA) : 85 dB(A)

Sound power level (LWA) : 96 dB (A) Uncertainty (K) : 3 dB(A)

Vibration

The vibration total value (tri-axial vector sum) determined according to EN60745:

Work mode: drilling into metal

Vibration emission (ah,D) : 2.5 m/s2 or less

Uncertainty (K) : 1.5 m/s2

NOTE: The declared vibration emission value has been measured in accordance with the standard test method and may be used for comparing one tool with another.

NOTE: The declared vibration emission value may also be used in a preliminary assessment of exposure.

EC Declaration of Conformity

For European countries only

The EC declaration of conformity is included as Annex A to this instruction manual.

SAFETY WARNINGS

General power tool safety warnings

Save all warnings and instructions for future reference.

The term “power tool” in the warnings refers to your mains-operated (corded) power tool or battery-operated (cordless) power tool.

Work area safety

- Keep work area clean and well-lit. Cluttered or dark areas invite accidents.

- Do not operate power tools in explosive atmospheres, such as in the presence of flammable liquids, gases or dust. Power tools create sparks that may ignite the dust or fumes.

- Keep children and bystanders away while operating a power tool. Distractions can cause you to lose control.

Electrical Safety

- Power tool plugs must match the outlet. Never modify the plug in any way. Do not use any adapter plugs with earthed (grounded) power tools. Unmodified plugs and matching outlets will reduce risk of electric shock.

- Avoid body contact with earthed or grounded surfaces, such as pipes, radiators, ranges, and refrigerators. There is an increased risk of electric shock if your body is earthed or grounded.

- Do not expose power tools to rain or wet conditions. Water entering a power tool will increase the risk of electric shock.

- Do not abuse the cord. Never use the cord for carrying, pulling, or unplugging the power tool. Keep cord away from heat, oil, sharp edges, or moving parts. Damaged or entangled cords increase the risk of electric shock.

- When operating a power tool outdoors, use an extension cord suitable for outdoor use. Use of a cord suitable for outdoor use reduces the risk of electric shock.

- If operating a power tool in a damp location is unavoidable, use a residual current device (RCD) protected supply. Use of an RCD reduces the risk of electric shock.

- Power tools can produce electromagnetic fields (EMF) that are not harmful to the user. However, users of pacemakers and other similar medical devices should contact the maker of their device and/or doctor for advice before operating this power tool.

Personal Safety

- Stay alert, watch what you are doing and use common sense when operating a power tool. Do not use a power tool while you are tired or under the influence of drugs, alcohol or medication. A moment of inattention while operating power tools may result in serious personal injury.

- Use personal protective equipment. Always wear eye protection. Protective equipment such as a dust mask, non-skid safety shoes, hard hat or hearing protection used for appropriate conditions will reduce personal injuries.

- Prevent unintentional starting. Ensure the switch is in the off-position before connecting to power source and/or battery pack, picking up or carrying the tool. Carrying power tools with your finger on the switch or energising power tools that have the switch on invites accidents.

- Remove any adjusting key or wrench before turning the power tool on. A wrench or a key left attached to a rotating part of the power tool may result in personal injury.

- Do not overreach. Keep proper footing and balance at all times. This enables better control of the power tool in unexpected situations.

- Dress properly. Do not wear loose clothing or jewellery. Keep your hair and clothing away from moving parts. Loose clothes, jewellery or long hair can be caught in moving parts.

- If devices are provided for the connection of dust extraction and collection facilities, ensure these are connected and properly used. Use of dust collection can reduce dust-related hazards.

- Do not let familiarity gained from frequent use of tools allow you to become complacent and ignore tool safety principles. A careless action can cause severe injury within a fraction of a second.

- Always wear protective goggles to protect your eyes from injury when using power tools. The goggles must comply with ANSI Z87.1 in the USA, EN 166 in Europe, or AS/NZS 1336 in Australia/New Zealand. In Australia/New Zealand, it is legally required to wear a face shield to protect your face, too.

It is an employer’s responsibility to enforce the use of appropriate safety protective equipments by the tool operators and by other persons in the immediate working area. Power tool use and care

- Do not force the power tool. Use the correct power tool for your application. The correct power tool will do the job better and safer at the rate for which it was designed.

- Do not use the power tool if the switch does not turn it on and off. Any power tool that cannot be controlled with the switch is dangerous and must be repaired.

- Disconnect the plug from the power source and/or remove the battery pack, if detachable, from the power tool before making any adjustments, changing accessories, or storing power tools. Such preventive safety measures reduce the risk of starting the power tool accidentally.

- Store idle power tools out of the reach of children and do not allow persons unfamiliar with the power tool or these instructions to operate the power tool. Power tools are dangerous in the hands of untrained users.

- Maintain power tools and accessories. Check for misalignment or binding of moving parts, breakage of parts, and any other condition that may affect the power tool’s operation. If damaged, have the power tool repaired before use. Many accidents are caused by poorly maintained power tools.

- Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting edges are less likely to bind and are easier to control.

- Use the power tool, accessories and tool bits etc. in accordance with these instructions, taking into account the working conditions and the work to be performed. Use of the power tool for operations different from those intended could result in a hazardous situation.

- Keep handles and grasping surfaces dry, clean and free from oil and grease. Slippery handles and grasping surfaces do not allow for safe handling and control of the tool in unexpected situations.

- When using the tool, do not wear cloth work gloves which may be entangled. The entanglement of cloth work gloves in the moving parts may result in personal injury.

Battery tool use and care

- Recharge only with the charger specified by the manufacturer. A charger that is suitable for one type of battery pack may create a risk of fire when used with another battery pack.

- Use power tools only with specifically designated battery packs. Use of any other battery packs may create a risk of injury and fire.

- When battery pack is not in use, keep it away from other metal objects, like paper clips, coins, keys, nails, screws or other small metal objects, that can make a connection from one terminal to another. Shorting the battery terminals together may cause burns or a fire.

- Under abusive conditions, liquid may be ejected from the battery; avoid contact. If contact accidentally occurs, flush with water. If liquid contacts eyes, additionally seek medical help. Liquid ejected from the battery may cause irritation or burns.

- Do not use a battery pack or tool that is damaged or modified. Damaged or modified batteries may exhibit unpredictable behaviour resulting in fire, explosion or risk of injury.

- Do not expose a battery pack or tool to fire or excessive temperature. Exposure to fire or temperature above 130 °C may cause explosion.

- Follow all charging instructions and do not charge the battery pack or tool outside the temperature range specified in the instructions. Charging improperly or at temperatures outside the specified range may damage the battery and increase the risk of fire.

Service

- Have your power tool serviced by a qualified repair person using only identical replacement parts. This will ensure that the safety of the power tool is maintained.

- Never service damaged battery packs. Service of battery packs should only be performed by the manufacturer or authorized service providers.

- Follow instruction for lubricating and changing accessories.

Cordless drill safety warnings

- Use auxiliary handle(s), if supplied with the tool. Loss of control can cause personal injury.

- Hold power tool by insulated gripping surfaces, when performing an operation where the cutting accessory may contact hidden wiring. Cutting accessory contacting a “live” wire may make exposed metal parts of the power tool “live” and could give the operator an electric shock.

- Always be sure you have a firm footing. Be sure no one is below when using the tool in high locations.

- Hold the tool firmly.

- Keep hands away from rotating parts.

- Do not leave the tool running. Operate the tool only when hand-held. 7. Do not touch the drill bit or the workpiece immediately after operation; they may be extremely hot and could burn your skin. 8. Some material contains chemicals which may be toxic. Take caution to prevent dust inhalation and skin contact. Follow material supplier safety data. 9. If the drill bit cannot be loosened even you open the jaws, use pliers to pull it out. In such a case, pulling out the drill bit by hand may result in injury by its sharp edge.

SAVE THESE INSTRUCTIONS.

Important safety instructions for battery cartridge

- Before using battery cartridge, read all instructions and cautionary markings on (1) battery charger, (2) battery, and (3) product using battery.

- Do not disassemble battery cartridge.

- If operating time has become excessively shorter, stop operating immediately. It may result in a risk of overheating, possible burns, and even an explosion.

- If electrolyte gets into your eyes, rinse them out with clear water and seek medical attention right away. It may result in loss of your eyesight.

- Do not short the battery cartridge:

(1) Do not touch the terminals with any conductive material.

(2) Avoid storing battery cartridge in a container with other metal objects such as nails, coins, etc.

(3) Do not expose battery cartridge to water or rain.

A battery short can cause a large current flow, overheating, possible burns, and even a breakdown. - Do not store the tool and battery cartridge in locations where the temperature may reach or exceed 50 °C (122 °F).

- Do not incinerate the battery cartridge even if it is severely damaged or is completely worn out. The battery cartridge can explode in a fire.

- Be careful not to drop or strike battery.

- Do not use a damaged battery.

- The contained lithium-ion batteries are subject to the Dangerous Goods Legislation requirements. For commercial transports e.g. by third parties, forwarding agents, special requirement on packaging and labeling must be observed. For preparation of the item being shipped, consulting an expert for hazardous material is required. Please also observe possibly more detailed national regulations. Tape or mask off open contacts and pack up the battery in such a manner that it cannot move around in the packaging.

- Follow your local regulations relating to disposal of battery.

- Use the batteries only with the products specified by Makita. Installing the batteries to non-compliant products may result in a fire, excessive heat, explosion, or leak of electrolyte.

SAVE THESE INSTRUCTIONS.

Tips for maintaining maximum battery life

- Charge the battery cartridge before completely discharged. Always stop tool operation and charge the battery cartridge when you notice less tool power.

- Never recharge a fully charged battery cartridge. Overcharging shortens the battery service life.

- Charge the battery cartridge with room temperature at 10 °C – 40 °C (50 °F – 104 °F). Let a hot battery cartridge cool down before charging it.

- Charge the battery cartridge if you do not use it for a long period (more than six months).

FUNCTIONAL DESCRIPTION

Installing or removing battery cartridge

To remove the battery cartridge, slide it from the tool while sliding the button on the front of the cartridge. To install the battery cartridge, align the tongue on the battery cartridge with the groove in the housing and slip it into place. Insert it all the way until it locks in place with a little click. If you can see the red indicator on the upper side of the button, it is not locked completely.

Indicating the remaining battery capacity

Only for battery cartridges with the indicator

Press the check button on the battery cartridge to indicate the remaining battery capacity. The indicator lamps light up for a few seconds.

Tool/battery protection system

The tool is equipped with a tool/battery protection system. This system automatically cuts off power to the motor to extend tool and battery life. The tool will automatically stop during operation if the tool or battery is placed under one of the following conditions:

Overload protection

When the tool/battery is operated in a manner that causes it to draw an abnormally high current, the tool stops automatically. In this situation, turn the tool off and stop the application that caused the tool to become overloaded. Then turn the tool on to restart.

Overheat protection

When the tool/battery is overheated, the tool stops automatically. In this situation, let the tool/battery cool before turning the tool on again.

Over-discharge protection

When the battery capacity is not enough, the tool stops automatically. In this case, remove the battery from the tool and charge the battery.

Main power switch

NOTE: This tool employs the auto power-off function. To avoid unintentional start-up, the main power switch will automatically shut down when the switch trigger is not pulled for a certain period after the main power switch is turned on.

Switch action

To start the tool, pull the switch trigger with the main power switch on. Tool speed is increased by increasing pressure on the switch trigger. Release the switch trigger to stop. NOTE: The tool automatically stops if you keep pulling the switch trigger for about 6 minutes.

Lighting up the front lamp

Pull the switch trigger to light up the lamp. The lamp keeps on lighting while the switch trigger is being pulled. The lamp goes out approximately 10 seconds after releasing the switch trigger.

NOTE: When the tool is overheated, the tool stops automatically and the lamp starts flashing. In this case, release the switch trigger. The lamp turns off in 5 minute.

NOTE: Use a dry cloth to wipe the dirt off the lens of the lamp. Be careful not to scratch the lens of lamp, or it may lower the illumination.

Reversing switch action

This tool has a reversing switch to change the direction of rotation. Depress the reversing switch lever from the A side for clockwise rotation or from the B side for counterclockwise rotation. When the reversing switch lever is in the neutral position, the switch lever cannot be pulled.

Automatic speed change function

This tool has “high speed mode” and “high torque mode”. The tool automatically changes the operation mode depending on the work load. When the work load is low, the tool will run in the “high speed mode” for quicker operation. When the work load is high, the tool will run in the “high torque mode” for powerful operation.

The mode indicator lights up in green when the tool is running in “high torque mode”. If the tool is operated with excessive load, the mode indicator will blink in green. The mode indicator stops blinking and then lights up or turns off if you reduce the load on the tool.

Speed change

NOTICE: Use the speed change knob only after the tool comes to a complete stop. Changing the tool speed before the tool stops may damage the tool.

NOTICE: Always set the speed change knob carefully into the correct position. If you operate the tool with the speed change knob positioned halfway between the position 1 and the position 2, the tool may be damaged. Two speed ranges can be preselected with the speed change knob. To change the speed, depress the lock button and turn the speed change knob so that the pointer points to the position 1 for low speed or the position 2 for high speed.

Torque limiter

The torque limiter will actuate when a certain torque level is reached at the low speed setting (position 1). The motor will disengage from the output shaft. When this happens, the drill bit will stop turning.

ASSEMBLY

Installing side grip (auxiliary handle)

Front handle

The front handle can be installed in any position within 0° – 112.5° as illustrated.

To change the position, loosen the hex bolts (both sides) with a hex wrench and turn the front handle to the desired position. Then tighten the hex bolts securely.

Installing or removing drill bit

To install the drill bit, place it in the chuck as far as it will go. Tighten the chuck by hand. Place the chuck key in each of the three holes and tighten clockwise. Be sure to tighten all three chuck holes evenly. To remove the drill bit, turn the chuck key counterclockwise in just one hole, then loosen the chuck by hand.

OPERATION

Holding tool

Grasp the handle with one hand and the front handle with the other hand.

When drilling a large hole with a self-feed bit, etc., the side grip (auxiliary handle) should be used as a brace to maintain safe control of the tool.

When drilling action is forward (clockwise), the tool should be braced to prevent a counterclockwise reaction if the bit should bind.

When reversing, brace the tool to prevent a clockwise reaction. If the drill bit must be removed from a partially drilled hole, be sure the tool is properly braced before reversing.

Drilling operation

Drilling in wood

When drilling in wood, the best results are obtained with wood drills equipped with a guide screw. The guide screw makes drilling easier by pulling the drill bit into the workpiece.

Drilling in metal

To prevent the drill bit from slipping when starting a hole, make an indentation with a center-punch and hammer at the point to be drilled. Place the point of the drill bit in the indentation and start drilling. Use a cutting lubricant when drilling metals. The exceptions are iron and brass which should be drilled dry.

Lanyard (tether strap) connection

Read all safety warnings and instructions. Failure to follow the warnings and instructions may result in serious injury.

- Always keep the tool tethered when working “at height”. Maximum lanyard length is 2 m (6.5 ft).

- Use only with lanyards appropriate for this tootype and rated for at least 7.0 kg (15.4 lbs).

- Do not anchor the tool lanyard to anything on your body or on movable components. Anchorthe tool lanyard to a rigid structure that can withstand the forces of a dropped tool.

- Make sure the lanyard is properly secured at each end prior to use.

- Inspect the tool and lanyard before each use for damage and proper function (including fabric and stitching). Do not use if damaged or not functioning properly.

- Do not wrap lanyards around or allow them to come in contact with sharp or rough edges.

- Fasten the other end of the lanyard outside the working area so that a falling tool is held securely.

- Attach the lanyard so that the tool will move away from the operator if it falls. Dropped tools will swing on the lanyard, which could cause injury or loss of balance.

- Do not use near moving parts or running machinery. Failure to do so may result in a crush or entanglement hazard.

- Do not carry the tool by the attachment device or the lanyard.

- Only transfer the tool between your hands while you are properly balanced.

- Do not attach lanyards to the tool in a way that keeps guards, switches or lock-offs from operating properly.

- Avoid getting tangled in the lanyard.

- Keep lanyard away from the cutting area of the tool.

- Use multi-action and screw gate type carabineers. Do not use single action spring clip carabineers.

- In the event the tool is dropped, it must be tagged and removed from service, and should be inspected by a Makita Factory or Authorized Service Center.

MAINTENANCE

NOTICE: Never use gasoline, benzine, thinner, alcohol or the like. Discoloration, deformation or cracks may result.

To maintain product SAFETY and RELIABILITY, repairs, any other maintenance or adjustment should be performed by Makita Authorized or Factory Service Centers, always using Makita replacement parts.

OPTIONAL ACCESSORIES

If you need any assistance for more details regarding these accessories, ask your local Makita Service Center.

- Drill bits

- Plastic carrying case

- Makita genuine battery and charger

NOTE: Some items in the list may be included in the tool package as standard accessories. They may differ from country to country.

Makita Europe N.V. Jan-Baptist Vinkstraat 2, 3070 Kortenberg, Belgium

Makita Corporation 3-11-8, Sumiyoshi-cho, Anjo, Aichi 446-8502 Japan

www.makita.com

885635-222 EN 20171220