Bosch GKS 235 Turbo Professional Hand-Held Circular Saw Instruction Manual

BOSCH GKS 235 Turbo Professional Hand-Held Circular Saw

Safety Instructions

Work Area Safety

- Keep work area clean and well lit. Cluttered or dark areas invite accidents.

- Do not operate power tools in explosive atmospheres, such as in the presence of flammable liquids, gases or dust. Power tools create sparks which may ignite the dust or fumes.

- Keep children and bystanders away while operating a power tool. Distractions can cause you to lose control.

Electrical Safety

- Power tool plugs must match the outlet. Never modify the plug in any way. Do not use any adapter plugs with earthed (grounded) power tools. Unmodified plugs and matching outlets will reduce risk of electric shock.

- Avoid body contact with earthed or grounded sur-faces, such as pipes, radiators, ranges and refrigerators. There is an increased risk of electric shock if your body is earthed or grounded.

- Do not expose power tools to rain or wet conditions. Water entering a power tool will increase the risk of electric shock.

- Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the power tool. Keep cord away from heat, oil, sharp edges or moving parts. Damaged or entangled cords increase the risk of electric shock.

- When operating a power tool outdoors, use an extension cord suitable for outdoor use. Use of a cord suit-able for outdoor use reduces the risk of electric shock.

- If operating a power tool in a damp location is un-avoidable, use a residual current device (RCD) protected supply. Use of an RCD reduces the risk of electric shock.

Personal Safety

- Stay alert, watch what you are doing and use common sense when operating a power tool. Do not use a power tool while you are tired or under the influence of drugs, alcohol or medication. A moment of inattention while operating power tools may result in serious personal injury.

- Use personal protective equipment. Always wear eye protection. Protective equipment such as a dust mask, non-skid safety shoes, hard hat or hearing protection used for appropriate conditions will reduce personal injuries.

- Prevent unintentional starting. Ensure the switch is in the off-position before connecting to power source and/or battery pack, picking up or carrying the tool. Carrying power tools with your finger on the switch or energizing power tools that have the switch on invites accidents.

- Remove any adjusting key or wrench before turning the power tool on. A wrench or a key left attached to a rotating part of the power tool may result in personal in-jury.

- Do not overreach. Keep proper footing and balance at all times. This enables better control of the power tool in unexpected situations.

- Dress properly. Do not wear loose clothing or jewelry. Keep your hair and clothing away from moving parts. Loose clothes, jewelry or long hair can be caught in moving parts.

- If devices are provided for the connection of dust ex-traction and collection facilities, ensure these are connected and properly used. Use of dust collection can re-duce dust-related hazards.

- Do not let familiarity gained from frequent use of tools allow you to become complacent and ignore tool safety principles. A careless action can cause severe in-jury within a fraction of a second.

Power Tool Use and Care

- Do not force the power tool. Use the correct power tool for your application. The correct power tool will do the job better and safer at the rate for which it was de-signed.

- Do not use the power tool if the switch does not turn it on and off. Any power tool that cannot be controlled with the switch is dangerous and must be repaired.

- Disconnect the plug from the power source and/or re-move the battery pack, if detachable, from the power tool before making any adjustments, changing accessories, or storing power tools. Such preventive safety measures reduce the risk of starting the power tool accidentally.

- Store idle power tools out of the reach of children and do not allow persons unfamiliar with the power tool or these instructions to operate the power tool. Power tools are dangerous in the hands of untrained users.

- Maintain power tools and accessories. Check for mis-alignment or binding of moving parts, breakage of parts and any other condition that may affect the power tool’s operation. If damaged, have the power tool repaired before use. Many accidents are caused by poorly maintained power tools.

- Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting edges are less likely to bind and are easier to control.

- Use the power tool, accessories and tool bits etc. in accordance with these instructions, taking into ac-count the working conditions and the work to be per-formed. Use of the power tool for operations different from those intended could result in a hazardous situation.

- Keep handles and grasping surfaces dry, clean and free from oil and grease. Slippery handles and grasping surfaces do not allow for safe handling and control of the tool in unexpected situations.

Service

- Have your power tool serviced by a qualified repair person using only identical replacement parts. This will ensure that the safety of the power tool is maintained.

Safety Instructions for Circular Saws

Cutting Procedures

- DANGER: Keep hands away from cutting area and the blade. Keep your second hand on auxiliary handle, or motor housing. If both hands are holding the saw, they cannot be cut by the blade.

- Do not reach underneath the workpiece. The guard cannot protect you from the blade below the workpiece.

- Adjust the cutting depth to the thickness of the work-piece. Less than a full tooth of the blade teeth should be visible below the workpiece.

- Never hold the workpiece in your hands or across your leg while cutting. Secure the workpiece to a stable platform. It is important to support the work properly to minimize body exposure, blade binding, or loss of con-trol.

- Hold the power tool by insulated gripping surfaces, when performing an operation where the cutting tool may contact hidden wiring or its own cord. Contact with a “live” wire will also make exposed metal parts of the power tool “live” and could give the operator an electric shock.

- When ripping always use a rip fence or straight edge guide. This improves the accuracy of cut and reduces the chance of blade binding.

- Always use blades with correct size and shape (diamond versus round) of arbor holes. Blades that do not match the mounting hardware of the saw will run off-center, causing loss of control.

- Never use damaged or incorrect blade washers or bolt. The blade washers and bolt were specially designed for your saw, for optimum performance and safety of operation.

Kickback Causes and Related Warnings

kickback is a sudden reaction to a pinched, jammed or misaligned saw blade, causing an uncontrolled saw to lift up and out of the workpiece toward the operator;

- when the blade is pinched or jammed tightly by the kerf closing down, the blade stalls and the motor reaction drives the unit rapidly back toward the operator;

- if the blade becomes twisted or misaligned in the cut, the teeth at the back edge of the blade can dig into the top surface of the wood causing the blade to climb out of the kerf and jump back toward the operator.

Kickback is the result of saw misuse and/or incorrect operating procedures or conditions and can be avoided by taking proper precautions as given below.

- Maintain a firm grip with both hands on the saw and position your arms to resist kickback forces. Position your body to either side of the blade, but not in line with the blade. Kickback could cause the saw to jump backwards, but kickback forces can be controlled by the operator, if proper precautions are taken.

- When blade is binding, or when interrupting a cut for any reason, release the trigger and hold the saw motionless in the material until the blade comes to a complete stop. Never attempt to remove the saw from the work or pull the saw backward while the blade is in motion or kickback may occur. Investigate and take corrective actions to eliminate the cause of blade binding.

- When restarting a saw in the workpiece, Centre the saw blade in the kerf so that the saw teeth are not engaged into the material. If a saw blade binds, it may walk up or kickback from the workpiece as the saw is restarted.

- Support large panels to minimize the risk of blade pinching and kickback. Large panels tend to sag under their own weight. Supports must be placed under the panel on both sides, near the line of cut and near the edge of the panel.

- Do not use dull or damaged blades. Unsharpened or im-properly set blades produce narrow kerf causing excessive friction, blade binding and kickback.

- Blade depth and bevel adjusting locking levers must be tight and secure before making the cut. If blade adjustment shifts while cutting, it may cause binding and kickback.

- Use extra caution when sawing into existing walls or other blind areas. The protruding blade may cut objects that can cause kickback.

Lower Guard Function

- Check the lower guard for proper closing before each use. Do not operate the saw if the lower guard does not move freely and close instantly. Never clamp or tie the lower guard into the open position. If the saw is accidentally dropped, the lower guard may be bent. Raise the lower guard with the retracting handle and make sure it moves freely and does not touch the blade or any other part, in all angles and depths of cut.

- Check the operation of the lower guard spring. If the guard and the spring are not operating properly, they must be serviced before use. Lower guard may operate sluggishly due to damaged parts, gummy deposits, or a build-up of debris.

- The lower guard may be retracted manually only for special cuts such as “plunge cuts” and “compound cuts”. Raise the lower guard by the retracting handle and as soon as the blade enters the material, the lower guard must be released. For all other sawing, the lower guard should operate automatically.

- Always observe that the lower guard is covering the blade before placing the saw down on bench or floor. An unprotected, coasting blade will cause the saw to walk backwards, cutting whatever is in its path. Be aware of the time it takes for the blade to stop after switch is released.

Additional Safety Warnings

- Do not allow the chip ejector to come into contact with your hands. You may be injured by rotating parts.

- Do not use the saw above the level of your head. Doing so will mean you have inadequate control of the power tool.

- Use suitable detectors to determine if utility lines are hidden in the work area or call the local utility company for assistance. Contact with electric lines can lead to fire and electric shock. Damaging a gas line can lead to explosion. Penetrating a water line causes property damage or may cause an electric shock.

- Hold the power tool firmly with both hands and make sure you have a stable footing. The power tool can be more securely guided with both hands.

- Do not operate the power tool when stationary. It is not suitable for operation with a saw table.

- When performing plunge cuts which are not right-angled, secure the guide plate of the saw so that it will not shift sideways. In the event of a sideways shift, the saw blade may become jammed, which could lead to kick-back.

- Secure the workpiece. A workpiece clamped with clamping devices or in a vice is held more secure than by hand.

- Always wait until the power tool has come to a complete stop before placing it down. The application tool can jam and cause you to lose control of the power tool.

- Do not use HSS saw blades. Such saw blades can easily break.

- Do not saw any ferrous metals. Hot chips may ignite the dust extractor.

- Wear a dust mask.

Products sold in GB only:

Your product is fitted with an BS 1363/A approved electric plug with internal fuse (ASTA approved to BS 1362).

If the plug is not suitable for your socket outlets, it should be cut off and an appropriate plug fitted in its place by an authorized customer service agent. The replacement plug should have the same fuse rating as the original plug.

The severed plug must be disposed of to avoid a possible shock hazard and should never be inserted into a mains socket elsewhere.

Product Description and Specifications

Intended Use

The power tool is intended for making straight cuts in wood with and against the grain and miter cuts in wood while resting firmly against the workpiece.

The power tool must not be used to cut ferrous metals.

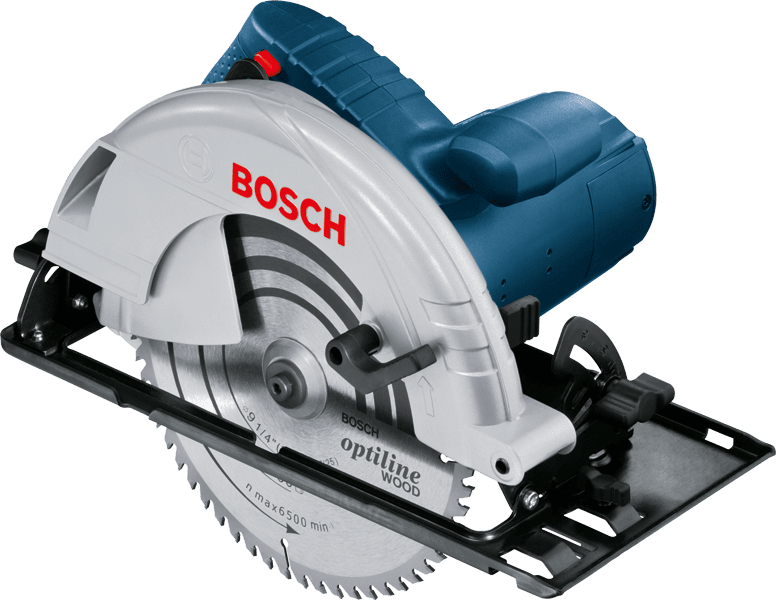

Product Features

The numbering of the product features refers to the diagram of the power tool on the graphics page.

- Protective guard

- Lock-on button for on/off switch

(3 601 EA2 0K./3 601 EA2 0L./3 601 EA2 0F.) - Lock-off button for on/off switch

(3 601 EA2 08./3 601 EA2 0B./3 601 EA2 04./ 3 601 EA2 00./3 601 EA2 07.) - On/off switch

- Auxiliary handle

- Spindle lock button

- Scale for miter/bevel angles

- Wing bolt for mitre/bevel angle preselection

- Wing bolt for parallel guide

- Cut mark 45°

- Cut mark 0°

- Parallel guide

- Retracting blade guard

- Adjusting lever for retracting blade guard

- Base plate

- Wing bolt for mitre/bevel angle preselection

- Chip ejector

- Hex key

- Clamping bolt with washer

- Clamping flange

- Circular saw blade

- Mounting flange

- Saw spindle

- Fastening screw for dust extraction adapter

- Dust extraction adapter

- Clamping lever for cutting depth preselection

- Cutting depth scale

- Pair of screw clamps

- Handle (insulated gripping surface)

Only for power tools without starting current limitation: Switching these on causes the voltage to drop briefly. Interference with other equipment may occur in the event of unfavorable conditions in the electricity supply. Malfunctions are not expected if the impedances in the electricity supply are below 0.14 ohms.

The specifications apply to a rated voltage [U] of 230 V. These specifications may vary at different voltages and in country-specific models.

Noise / Vibration Information

Noise emission values determined according to EN 62841-2-5.

Typically, the A-weighted noise level of the power tool is: Sound pressure level 92 dB(A); sound power level 103 dB(A). Uncertainty K = 3 dB.

Wear hearing protection!

Vibration total values ah (triax vector sum) and uncertainty K determined according to EN 62841-2-5:

Sawing wood: ah = 3.3 m/s2, K = 1.5 m/s2

The vibration level and noise emission value given in these instructions have been measured in accordance with a standardized measuring procedure and may be used to com-pare power tools. They may also be used for a preliminary estimation of vibration and noise emissions.

The stated vibration level and noise emission value represent the main applications of the power tool. However, if the power tool is used for other applications, with different ap-plication tools or is poorly maintained, the vibration level and noise emission value may differ. This may significantly increase the vibration and noise emissions over the total working period.

To estimate vibration and noise emissions accurately, the times when the tool is switched off or when it is running but not actually being used should also be taken into account. This may significantly reduce vibration and noise emissions over the total working period.

Implement additional safety measures to protect the operator from the effects of vibration, such as servicing the power tool and application tools, keeping their hands warm, and organizing workflows correctly.

Fitting

- Only use saw blades the maximum permitted speed of which is higher than the no-load speed of the power tool.

Inserting/Changing the Circular Saw Blade

- Pull the plug out of the socket before carrying out any work on the power tool.

- Wear protective gloves when fitting the saw blade. Danger of injury when touching the saw blade.

- Do not use abrasive wheels as the application tool un-der any circumstances.

- Only use saw blades that match the specifications given in this operating manual and on the power tool.

Selecting the Saw Blade

You will find an overview of recommended saw blades at the end of these operating instructions.

Removing the Saw Blade

To change tools, we recommend that you place the power tool down on the front side of the motor housing.

– Press and hold the spindle lock button (5).

- Do not press the spindle lock button (5) while the saw spindle is moving. The power tool may become damaged if this happens.

- Use the hex key (17) to undo the clamping bolt (18) in rotational direction.

- Swing the retracting blade guard (12) back and hold on to it firmly.

- Remove the clamping flange (19) and the saw blade (20) from the saw spindle (22).

Fitting the Saw Blade

To change tools, we recommend that you place the power tool down on the front side of the motor housing.

- Clean the saw blade (20) and all the clamping elements to be fitted.

- Swing the retracting blade guard (12) back and hold on to it firmly.

- Place the saw blade (20) on the mounting flange (21). The cutting direction of the teeth (direction of the arrow on the saw blade) must match the rotational direction of the arrow on the protective guard (1).

- Attach the clamping flange (19) and screw in the clamping bolt (18) in rotational direction. Ensure that the mounting flange (21) and clamping flange (19) are in-stalled in the correct position.

- Press and hold the spindle lock button (5).

- Use the hex key (17) to tighten the clamping bolt (18) in rotational direction. The tightening torque should be 10-12 Nm, which corresponds to hand-tight plus ¼ turn.

Dust/Chip Extraction

The dust from materials such as lead paint, some types of wood, minerals and metal can be harmful to human health. Touching or breathing in this dust can trigger allergic reac-tions and/or cause respiratory illnesses in the user or in people in the near vicinity.

Certain dusts, such as oak or beech dust, are classified as carcinogenic, especially in conjunction with wood treatment additives (chromate, wood preservative). Materials contain-ing asbestos may only be machined by specialists.

- Use a dust extraction system that is suitable for the material wherever possible.

- Provide good ventilation at the workplace.

- It is advisable to wear a P2 filter class breathing mask.

The regulations on the material being machined that apply in the country of use must be observed.

- Avoid dust accumulation at the workplace. Dust can easily ignite.

Fitting the Dust Extraction Adapter

Push the dust extraction adapter (24) onto the chip ejector (16) until it clicks into place. Then secure the dust extraction adapter (24) in place with the screw (23).

A dust extraction hose with a diameter of 35 mm can be connected to the dust extraction adapter (24).

- The dust extraction adapter must only be fitted if an external dust extraction system is connected. Other-wise the extraction duct can become clogged.

- No dust bags should be connected to the dust extraction adapter. Otherwise the extraction system can be-come clogged.

To ensure optimum extraction, the dust extraction adapter (24) must be cleaned regularly.

External Dust Extraction

The power tool can be directly connected to the socket of a Bosch all-purpose dust extractor with remote starter. This dust extractor is started up automatically when the power tool is switched on.

The dust extractor must be suitable for the material being worked.

When vacuuming dry dust that is especially detrimental to health or carcinogenic, use a special dust extractor.

In Germany, wood dust extraction requires extraction devices which have been tested on the basis of TRGS 553; self-generated dust extraction must not be used in the commercial sector. Commercial operators must clarify the specific requirements for other materials with the responsible trade association.

Operation

- Pull the plug out of the socket before carrying out any work on the power tool.

Operating Modes

Setting the Cutting Depth

- Adapt the cutting depth to the thickness of the work-piece. A space of less than the height of one full tooth should be visible under the workpiece.

Loosen the clamping lever (25). For a smaller cutting depth, pull the saw away from the base plate (14); for a larger cut-ting depth, push the saw towards the base plate (14). Adjust the desired cutting depth at the cutting-depth scale. Retighten the clamping lever (25).

The clamping force of the clamping lever (25) can be readjusted. To do so, unscrew the clamping lever (25) and retighten it in a position offset by at least 30° in an anticlockwise direction.

Adjusting the Mitre Angle

We recommend that you place the power tool down on the front side of the protective guard (1).

Loosen the wing bolts (7) and (15). Swivel the saw to the side. Set the required mitre angle on the scale (6). Retighten the wing bolts (7) and (15).

Note: When making mitre cuts, the cutting depth is less than the value shown on the cutting depth scale (26).

Cut Marks

The 0° cut mark (10) indicates the position of the saw blade when making a right-angled cut. The 45° cut mark (9) indicates the position of the saw blade when making a 45° cut. For a precise cut, place the circular saw against the work-piece as shown in the figure. We recommend making a test cut.

Start-up

- Pay attention to the mains voltage. The voltage of the power source must match the voltage specified on the rating plate of the power tool. Power tools marked with 230V can also be operated with 220V.

- Products that are only sold in AUS and NZ: Use a residual current device (RCD) with a nominal residual current of 30 mA or less.

Switching on/off

- Make sure that you are able to press the On/Off switch without releasing the handle.

3 601 EA2 0K./3 601 EA2 0L./3 601 EA2 0F.:

To start the power tool, press and hold the on/off switch (3).

Press the lock-on button (2) to lock the on/off switch (3) in this position.

To switch off the power tool, release the on/off switch (3); or, if the switch is locked with the lock-on button (2), briefly press the on/off switch (3) and then release it.

3 601 EA2 08./3 601 EA2 0B./3 601 EA2 04./

3 601 EA2 00./3 601 EA2 07.:

To start the power tool, first press the lock-off switch (2), then press and hold the on/off switch (3).

To switch off the power tool, release the on/off switch (3).

Note: For safety reasons, the on/off switch (3) cannot be locked; it must remain pressed during the entire operation.

Practical Advice

- Pull the plug out of the socket before carrying out any work on the power tool.

The width of cut varies depending on the saw blade used. Protect saw blades against shock and impact.

Guide the power tool evenly, pushing it gently in the cutting direction. Applying too much pressure to the power tool when moving it in the cutting direction significantly reduces the service life of the application tools and can damage the power tool.

The sawing performance and the quality of the cut essentially depend on the condition and the tooth shape of the saw blade. This is why you should only use sharp saw blades that are suitable for the material being machined.

Sawing Wood

Choosing the right saw blade depends on the wood type, wood quality and whether cuts with or against the grain are required.

Making cuts in spruce with the grain produces long, spiral-shaped chips.

Beech and oak dust is especially detrimental to health. Therefore, work only with dust extraction.

Sawing with a Parallel Guide

The parallel guide (11) allows you to make precise cuts along the edge of a workpiece and cut strips with the same dimensions.

Loosen the wing bolt (8) and slide the scale of the parallel guide (11) through the guide in the base plate (14). Adjust the desired cutting width as a scale value at the correspond-ing (10) or (9) cut mark, see the section “Cut marks”. Retighten the wing bolt (8).

Sawing with an Auxiliary Guide

For working on large workpieces or for cutting straight edges, you can securely fasten a board or rail to the work-piece as an auxiliary guide. The circular saw can be guided along the path of this auxiliary guide with the base plate.

Maintenance and Service

Maintenance and Cleaning

- Pull the plug out of the socket before carrying out any work on the power tool.

- To ensure safe and efficient operation, always keep the power tool and the ventilation slots clean.

In order to avoid safety hazards, if the power supply cord needs to be replaced, this must be done by Bosch or by an after-sales service Centre that is authorized to repair Bosch power tools.

The retracting blade guard must always be able to move freely and retract automatically. It is therefore important to keep the area around the retracting blade guard clean at all times. Remove dust and chips with a paintbrush.

Non-coated saw blades can be protected against corrosion using a thin layer of acid-free oil. Remove the oil again before sawing as failure to do so will stain the wood.

Resin or glue residue on the saw blade has a detrimental effect on the quality of the cut. You should therefore clean saw blades straight after use.

After-Sales Service and Application Service

Our after-sales service responds to your questions concerning maintenance and repair of your product as well as spare parts. You can find explosion drawings and information on spare parts at: www.bosch-pt.com

The Bosch product use advice team will be happy to help you with any questions about our products and their accessories.

In all correspondence and spare parts orders, please always include the 10‑digit article number given on the nameplate of the product.

Malaysia

Robert Bosch Sdn. Bhd.(220975-V) PT/SMY

No. 8A, Jalan 13/6

46200 Petaling Jaya

Selangor

Tel.: (03) 79663194

Toll-Free: 1800 880188

Fax: (03) 79583838

Email:

www.bosch-pt.com.my

You can find further service addresses at:

www.bosch-pt.com/serviceaddresses