Bosch GWS 18V-15 C Professional Cordless Angle Grinder Instructions

18V-15 C | 18V-15 SC

Original instructions

| L-BOXX 136 1 600 A01 2G0 | |

| 6 082 850 6DU | |

| 1 600 A01 3WF |

Safety instructions

General Power Tool Safety Warnings

tool.

Work area safety

- Keep the work area clean and well-lit. Cluttered or dark areas invite accidents.

- Do not operate power tools in explosive atmospheres, such as in the presence of flammable liquids, gases, or dust. Power tools create sparks that may ignite dust or fumes.

- Keep children and bystanders away while operating a power tool. Distractions can cause you to lose control.

Electrical safety - Power tool plugs must match the outlet. Never modify the plug in any way. Do not use any adapter plugs with earthed (grounded) power tools. Unmodified plugs and matching outlets will reduce the risk of electric shock.

- Avoid body contact with earthed or grounded surfaces, such as pipes, radiators, ranges, and refrigerators. There is an increased risk of electric shock if your body is earthed or grounded.

- Do not expose power tools to rain or wet conditions. Water entering a power tool will increase the risk of electric shock.

- Do not abuse the cord. Never use the cord for carrying, pulling, or unplugging the power tool. Keep cord away from heat, oil, sharp edges, or moving parts. Damaged or entangled cords increase the risk of electric shock.

- When operating a power tool outdoors, use an extension cord suitable for outdoor use. The use of a cord suitable for outdoor use reduces the risk of electric shock..

- If operating a power tool in a damp location is un-avoidable, use a residual current device (RCD) protected supply. The use of an RCD reduces the risk of electric shock.

Personal safety - Stay alert, watch what you are doing, and use common sense when operating a power tool. Do not use a power tool while you are tired or under the influence of drugs, alcohol, or medication. A moment of inattention while operating power tools may result in serious per- sonal injury.

- Use personal protective equipment. Always wear eye protection. Protective equipment such as dust masks, non-skid safety shoes, hard hats, or hearing protection used for appropriate conditions will reduce personal injuries.

- Prevent unintentional starting. Ensure the switch is in the off-position before connecting to a power source and/or battery pack, picking up or carrying the tool. Carrying power tools with your finger on the switch or energizing power tools that have the switch on invites accidents.

- Remove any adjusting key or wrench before turning the power tool on. A wrench or a key left attached to a rotating part of the power tool may result in personal injury.

- Do not overreach. Keep proper footing and balance at all times. This enables better control of the power tool in unexpected situations.

- Dress properly. Do not wear loose clothing or jewelry. Keep your hair, clothing, and gloves away from moving parts. Loose clothes, jewelry, or long hair can be caught in moving parts.

- If devices are provided for the connection of dust extraction and collection facilities, ensure these are connected and properly used. The use of dust collection can reduce dust-related hazards.

Power tool use and care - Do not force the power tool. Use the correct power tool for your application. The correct power tool will do the job better and safer at the rate at which it was designed.

- Do not use the power tool if the switch does not turn on and off. Any power tool that cannot be controlled with the switch is dangerous and must be repaired.

- Disconnect the plug from the power source and/or the battery pack from the power tool before making any adjustments, changing accessories, or storing power tools. Such preventive safety measures reduce the risk of starting the power tool accidentally.

- Store idle power tools out of the reach of children and do not allow persons unfamiliar with the power tool or these instructions to operate the power tool. Power tools are dangerous in the hands of untrained users.

- Maintain power tools. Check for misalignment or binding of moving parts, breakage of parts, and any other condition that may affect the power tool’s operation. If damaged, have the power tool repaired before use. Many accidents are caused by poorly maintained power tools.

- Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting edges are less likely to bind and are easier to control.

- Use the power tool, accessories and tool bits, etc. in accordance with these instructions, taking into account the working conditions and the work to be performed. Use of the power tool for operations different from those intended could result in a hazardous situation.

Battery tool use and care - Recharge only with the charger specified by the manufacturer. A charger that is suitable for one type of battery pack may create a risk of fire when used with another battery pack.

- Use power tools only with specifically designated battery packs. Use of any other battery packs may create a risk of injury and fire.

- When the battery pack is not in use, keep it away from other metal objects, like paper clips, coins, keys, nails, screws, or other small metal objects, that can make a connection from one terminal to another. Shorting the battery terminals together may cause burns or a fire.

- Under abusive conditions, liquid may be ejected from the battery; avoid contact. If contact accidentally occurs, flush with water. If liquid contacts eyes, additionally seek medical help. Liquid ejected from the battery may cause irritation or burns.

Service - Have your power tool serviced by a qualified repair person using only identical replacement parts. This will ensure that the safety of the power tool is maintained. Safety information for the angle grinder Safety Warnings common for Grinding, Sanding, Wire Brushing, or Abrasive Cutting Off operations

- This power tool is intended to function as a grinder, sander, wire brush, or cut-off tool. Read all safety warnings, instructions, illustrations, and specifications provided with this power tool. Failure to follow all instructions listed below may result in electric shock, fire, and/or serious injury.

- Operations such as polishing are not recommended to be performed with this power tool. Operations for which the power tool was not designed may create a hazard and cause personal injury.

- Do not use accessories that are not specifically designed and recommended by the tool manufacturer. Just because the accessory can be attached to your power tool, it does not assure safe operation.

- The rated speed of the accessory must be at least equal to the maximum speed marked on the power tool. Accessories running faster than their rated speed can break and fly apart.

- The outside diameter and the thickness of your accessory must be within the capacity rating of your power tool. Incorrectly sized accessories cannot be adequately guarded or controlled.

- Threaded mounting of accessories must match the grinder spindle thread. For accessories mounted by flanges, the arbor hole of the accessory must fit the locating diameter of the flange. Accessories that do not match the mounting hardware of the power tool will run out of balance, vibrate excessively, and may cause loss of control.

- Do not use a damaged accessory. Before each use inspects the accessory such as abrasive wheels for chips and cracks, backing pad for cracks, tear, or excess wear, wire brush for loose or cracked wires. If a power tool or accessory is dropped, inspect for damage or install an undamaged accessory. After inspecting and installing an accessory, position yourself and bystanders away from the plane of the rotating accessory and run the power tool at maximum no-load speed for one minute. Damaged accessories will normally break apart during this test time.

- Wear personal protective equipment. Depending on the application, use a face shield, safety goggles, or safety glasses. As appropriate, wear a dust mask, hearing protectors, gloves, and a workshop apron capable of stopping small abrasive or workpiece fragments. The eye protection must be capable of stopping flying debris generated by various operations. The dust mask or respirator must be capable of filtrating particles generated by your operation. Prolonged exposure to high-intensity noise may cause hearing loss.

- Keep bystanders a safe distance away from the work area. Anyone entering the work area must wear personal protective equipment. Fragments of workpiece or of a broken accessory may fly away and cause injury beyond the immediate area of operation.

- Hold the power tool by insulated gripping surfaces only when performing an operation where the cutting accessory may contact hidden wiring. Cutting accessory contacting a “live” wire may make exposed metal parts of the power tool “live” and could give the operator an electric shock.

- Never lay the power tool down until the accessory has come to a complete stop. The spinning accessory may grab the surface and pull the power tool out of your control.

- Do not run the power tool while carrying it at your side. Accidental contact with the spinning accessory could snag your clothing, pulling the accessory into your body.

- Regularly clean the power tool’s air vents. The motor’s fan will draw the dust inside the housing and excessive accumulation of powdered metal may cause electrical hazards.

- Do not operate the power tool near flammable materials. Sparks could ignite these materials.

- Do not use accessories that require liquid coolants. Using water or other liquid coolants may result in electrocution or shock.

Kickback and Related Warnings

Kickback is a sudden reaction to a pinched or snagged rotating wheel, backing pad, brush, or any other accessory. Pinching or snagging causes rapid stalling of the rotating accessory which in turn causes the uncontrolled power tool to be forced in the direction opposite of the accessory’s rotation at the point of the binding. For example, if an abrasive wheel is snagged or pinched by the workpiece, the edge of the wheel that is entering into the pinch point can dig into the surface of the material causing the wheel o to climb out or kick out. The wheel may either jump toward or away from the operator, depending on the direction of the wheel’s movement at the point of pinching. Abrasive wheels may also break under these conditions. Kickback is the result of power tool misuse and/or incorrect operating procedures or conditions and can be avoided by taking proper precautions as given below. - Maintain a firm grip on the power tool and position your body and arm to allow you to resist kickback forces. Always use an auxiliary handle, if provided, for maximum control over kickback or torque reaction during start-up. The operator can control torque reactions or kickback forces if proper precautions are taken.

- Never place your hand near the rotating accessory. The accessory may kick back over your hand.

- Do not position your body in the area where the power tool will move if kickback occurs. Kickback will propel the tool in a direction opposite to the wheel’s movement at the point of snagging. special care when working corners, sharp edges, etc. Avoid bouncing and snagging the accessory. Corners, sharp edges, or bouncing have a tendency to snag the rotating accessory and cause loss of control or kickback.

- Do not attach a saw chain woodcarving blade or toothed saw blade. Such blades create frequent kickback and loss of control.

Safety Warnings Specific for Grinding and abrasive Cutting-Off operations - Use only wheel types that are recommended for your power tool and the specific guard designed for the selected wheel. Wheels for which the power tool was not designed can not be adequately guarded and are unsafe.

- The grinding surface of center depressed wheels must be mounted below the plane of the guard lip. An improperly mounted wheel that projects through the plane of the guard lip cannot be adequately protected.

- The guard must be securely attached to the power tool and positioned for maximum safety, so the least amount of wheel is exposed towards the operator. The guard helps to protect the operator from broken wheel fragments, accidental contact with the wheel, and sparks that could ignite clothing.

- Wheels must be used only for recommended applications. For example: do not grind with the side of the cutoff wheel. Abrasive cut-off wheels are intended for peripheral grinding, side forces applied to these wheels may cause them to shatter.

- Always use undamaged wheel flanges that are of the correct size and shape for your selected wheel. Proper wheel flanges support the wheel thus reducing the possibility of wheel breakage. Flanges for cut-off wheels may be different from grinding wheel flanges.

- Do not use worn down wheels from larger power tools. A wheel intended for a larger power tool is not suitable for the higher speed of a smaller tool and may burst. Additional Safety Warnings Specific for Abrasive Cutting Off operations

- Do not “jam” the cut-off wheel or apply excessive pressure. Do not attempt to make an excessive depth of cut. Overstressing the wheel increases the loading and susceptibility to twisting or binding of the wheel in the cut and the possibility of kickback or wheel breakage.

- Do not position your body in line with and behind the rotating wheel. When the wheel, at the point of operation, is moving away from your body, the possible kickback may propel the spinning wheel and the power tool directly at you.

- When the wheel is binding or when interrupting a cut for any reason, switch off the power tool and hold the power tool motionless until the wheel comes to a complete stop. Never attempt to remove the cut-off wheel from the cut while the wheel is in motion otherwise kickback may occur. Investigate and take corrective action to eliminate the use of wheel binding.

- Do not restart the cutting operation in the workpiece. Let the wheel reach full speed and carefully re-enter the cut. The wheel may bind, walk up or kick back if the power tool is restarted in the workpiece.

- Support panels or any oversized workpiece to minimize the risk of wheel pinching and kickback. Large workpieces tend to sag under their own weight. Supports must be placed under the workpiece near the line of cut and near the edge of the workpiece on both sides of the wheel.

- Use extra caution when making a “pocket cut” into existing walls or other blind areas. The protruding wheel may cut gas or water pipes, electrical wiring, or objects that can cause kickback. Safety warnings specific for Sanding operations

- Do not use excessively oversized sanding disc paper. Follow manufacturer’s recommendations, when selecting sanding paper. Larger sanding paper extending beyond the sanding pad presents a laceration hazard and may cause snagging, tearing of the disc, or kickback. Safety warnings specific for Wire Brushing operations

- Be aware that wire bristles are thrown by the brush even during ordinary operations. Do not overstress the wires by applying excessive load to the brush The wire bristles can easily penetrate light clothing and/or skin.

- If the use of a guard is recommended for wire brushing, do not allow any interference of the wire wheel or brush with the guard. Wire wheel or brush may expand in diameter due to workload and centrifugal forces.

- Use suitable detectors to determine if there are hidden supply lines or contact the local utility company for assistance. Contact with electric cables can cause fire and electric shock. Damaging gas lines can lead to explosions. Breaking water pipes causes property damage.

- Do not touch grinding and cutting discs until they have cooled down. The discs can become very hot while working.

- Release the On/Off switch and set it to the Off position when the power supply is interrupted, e.g. when the battery pack is removed. This prevents uncontrolled restarting.

- Secure the workpiece. A workpiece clamped with clamping devices or in a vice is held more secure than by hand.

- In case of damage and improper use of the battery, vapors may be emitted. The battery can set alight or explode. Ensure the area is well ventilated and seek medical attention should you experience any adverse effects. The vapors may irritate the respiratory system.

- Do not open the battery. There is a risk of short-circuiting.

- The battery can be damaged by pointed objects such as nails or screwdrivers or by force applied externally. An internal short circuit may occur, causing the battery to burn, smoke, explode or overheat.

- Only use the battery with products from the manufacturer. This is the only way in which you can protect the battery against dangerous overload.

- Caution! When using the power tool with Bluetooth ®, a fault may occur in other devices and systems, airplanes, and medical devices (e.g. pacemakers, hearing aids). Also, damage to people and animals in the immediate vicinity cannot be completely excluded. Do not use the power tool with Bluetooth ® in the vicinity of medical devices, petrol stations, chemical plants, areas with a potentially explosive atmosphere, or in blasting areas. Do not use the power tool with Bluetooth ® in aircraft. Avoid using the product near

your body for extended periods. The Bluetooth® word mark and logos are registered trademarks owned by Bluetooth SIG, Inc. and any use of such marks by Robert Bosch ower Tools GmbH is under license.

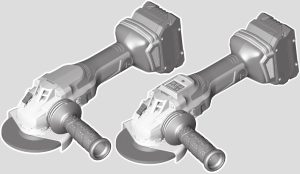

Product Description and Specifications

Intended use

The power tool is intended for cutting, roughing, and brushing metal and stone materials without the use of water. A special protective guard for cutting must be used when cutting bonded abrasives. Sufficient dust extraction must be provided when cutting stone. With approved abrasive tools, the power tool can be used for sanding with sanding discs. With the Bluetooth ® Low Energy Module GCY 42 inserted, power tool data and settings can be transferred between the power tool and a mobile device by means of Bluetooth ® wireless technology.

Product Features

The numbering of the product features refers to the diagram of the power tool on the graphics page.

| (1) Unlocking lever for protective guard (2) Direction of rotation arrow on the housing (3) Spindle lock button (4) User interface (5) On/off switch (6) Cover for GCY 42 Bluetooth® Low Energy Module (7) Battery A) (8) Battery release button A) (9) Auxiliary handle (insulated gripping surface) (10) Protective guard for grinding (11) Mounting flange with O‑ring (12) Grinding disc (13) Clamping nut (14) Carbide grinding head (15) Protective guard for cutting (16) Cutting disc A) |

(17) Handle (insulated gripping surface) (18) Grinding spindle (19) Handguard A) (20) Rubber sanding pad A) (21) Abrasive disc A) (22) Round nut A) (23) Cup brush A) (24) Diamond core bit A) (25) Battery charge indicator (user interface) (26) Kickback shutdown indicator (user interface) (27) Speed preselection button (user interface) (28) Speed setting/mode indicator (user interface) (29) Smartphone indicator (user interface) (30) Power tool status indicator (user interface) (31) Temperature indicator (user interface) (32) Flap disc A) A) Accessories shown or described are not included with the product as standard. You can find the complete selection of accessories in our accessories range. |

Technical Data

| Angle grinder | GWS 18V-15 C | GWS 18V-15 SC | |

| Article number | 3 601 JH6 0.. | 3 601 JH6 1.. | |

| Rated voltage | V= | 18 | 18 |

| Rated speed”‘ | min.’ | 11,000 | 11,000 |

| No-load speed’) | min’ | 9800 | 3400-9800 |

| Max. grinding disc diameter | mm | 100 | 100 |

| Grinding spindle thread | M 10 | M 10 | |

| Max. thread length of grinding spindle | mm | 16 | 16 |

| Kickback stop | • | • | |

| Restart protection | • | • | |

| Run-out brake | • | • | |

| Speed preselection | • | ||

| Weight according to EPTA-Procedure 01:20140 | |||

| – with low-vibration auxiliary handle | kg | 2.5-3.5 | 2.5-3.5 |

| – with standard auxiliary handle | kg | 2.3-3.3 | 2.3-3.3 |

| Recommended ambient temperature during charging | °C | 0 … +35 | 0 … +35 |

| Permitted ambient temperature during operation) and during storage | °C | -20 … +50 | -20 … +50 |

| Compatible rechargeable batteries | GBA 18V… ProCORE18V… | GBA 18V… ProCORE18V… | |

| Recommended rechargeable batteries for maximum performance | ProCORE18V… 5.5 Ah | ProCORE18V… > 5.5 Ah | |

| Recommended chargers | GAL 18… GAX 18… GAL 36… | GAL 18… GAX 18… GAL 36… il | |

| Data transmission | |||

| Bluetooth | Bluetooth® 4.2 (Low Energy) E) | Bluetooth® 4.2 (Low Energy) E) | |

| Signal interval | s | 8 | 8 |

| Max. signal range F) | m | 30 | 30 |

A) Rated speed in accordance with EN 60745-2-3

B) Measured at 20–25 °C with rechargeable battery ProCORE18V 8.0Ah and depending on the battery’s state of charge as well as the tool’s operating temperature

C) Depends on battery in use

D) Limited performance at temperatures <0 °C

E) The mobile terminal devices must be compatible with Bluetooth ® Low Energy devices (version 4.2) and support the Generic Access Profile (GAP).

F) The signal range may vary greatly depending on external conditions, including the receiving device used. The Bluetooth® range may be significantly weaker inside closed rooms and through metallic barriers (e.g. walls, shelving units, cases, etc.).

Fitting

Using the GCY 42 Bluetooth® Low Energy Module

Note: The GCY 42 Bluetooth ® Low Energy Module is available as an accessory with GWS 18V-15 C power tools; it is included in the scope of delivery for GWS 18V-15 SC power tools. Read the corresponding operating instructions for information about the Bluetooth® Low Energy Module GCY 42.

Charging the battery

- Use only the chargers listed in the technical data. Only these chargers are matched to the lithium-ion battery of your power tool.

Note: The battery is supplied partially charged. To ensure full battery capacity, fully charge the battery in the charger before using your power tool for the first time. The lithium-ion battery can be charged at any time without reducing its service life. Interrupting the charging process does not damage the battery. The lithium-ion battery is protected against deep discharge by the “Electronic Cell Protection (ECP)”. When the battery is discharged, the power tool is switched off by means of a protective circuit: The application tool no longer rotates. - Do not continue to press the On/Off switch after the power tool has automatically switched off. The battery can be damaged. Follow the instructions on the correct disposal.

Removing the Battery

The battery (7) is equipped with two locking levels to prevent the battery from falling out if the battery release button (8) is pressed unintentionally. As long as the battery is inserted in the power tool, it is held in position by means of a spring. To remove the battery (7), press the release button (8) and pull the battery out of the power tool. Do not use force to do this.

Battery charge indicator

The green LEDs on the battery charge indicator indicate the state of charge of the battery. For safety reasons, it is only possible to check the state of charge when the power tool is not in operation. Press the button for the battery charge indicator to show the state of charge. This is also possible when the battery is removed. If no LED lights up after pressing the button for the battery charge indicator, then the battery is defective and must be replaced.

Note: The state of charge of the battery is also displayed on the user interface (4) (see “Status Indicators”, page 14). or

Battery model GBA 18V…

| LEDs | Capacity |

| 3× continuous green light | 60−100 % |

| 2× continuous green light | 30−60 % |

| 1× continuous green light | 5−30 % |

| 1× flashing green light | 0−5 % |

Battery model ProCORE18V…

| LEDs | Capacity |

| 5× continuous green light | 80−100 % |

| 4× continuous green light | 60−80 % |

| 3× continuous green light | 40−60 % |

| 2× continuous green light | 20−40 % |

| 1× continuous green light | 5−20 % |

| 1× flashing green light | 0−5 % |

Fitting Protective Equipment

- Remove the battery from the power tool before carrying out work on the power tool (e.g. maintenance, changing tool, etc.). The battery should also be removed for transport and storage. There is a risk of injury from unintentionally pressing the on/off switch.

Note: If the grinding disc breaks during operation or the holding fixtures on the protective guard/power tool become damaged, the power tool must be sent to the after-sales service immediately; see the “After-Sales Service and Application Service” section for addresses.

A protective guard for grinding

Place the protective guard (10) onto the holder on the power tool until the coding cams of the protective guard are aligned with the holder. When doing so, press and hold the unlocking lever (1). Press the protective guard (10) onto the spindle collar until the shoulder of the protective guard is sitting on the flange of the power tool and rotate the protective guard until it audibly clicks into place. Adjust the position of the protective guard (10) to meet the requirements of the operation. To do this, push the unlocking lever

(1) upward and rotate the protective guard (10) into the required position.

- Always position the protective guard (10) such that the two cams on the unlocking lever (1) engage in the corresponding openings on the protective guard (10).

- Adjust the protective guard (10) such that spark in the direction of the operator is prevented.

- The protective guard (10) must only be adjustable while the unlocking lever (1) is actuated. Otherwise, the power tool must not be used anymore under any circumstances and must be sent to the after-sales service.

Note: The coding cams on the protective guard (10) ensure that only a protective guard that is suitable for the power tool can be fitted. A protective guard for cutting - Always use the protective guard for cutting (15) when cutting bonded abrasives.

- Provide sufficient dust extraction when cutting stone. The protective guard for cutting (15) is fitted in the same way as the protective guard for grinding (10). Side handle

- Do not operate your power tool without the side handle (9). Screw the side handle (9) on the left or right of the machine head depending on how you are working.

Low-vibration auxiliary handle

The low-vibration auxiliary handle reduces vibration, enabling the tool to be used safely and more comfortably.

- Do not make any alterations of any kind to the auxiliary handle.

Do not continue to use a damaged auxiliary handle.

Handguard - Always fit the handguard (19) when working with the rubber sanding plate (20) or with the cup brush/disc brush/flap disc. Attach the handguard (19) to the side handle (9).

Fitting the abrasive tools - Remove the battery from the power tool before carrying out work on the power tool (e.g. maintenance, changing tool, etc.). The battery should also be removed for transport and storage. There is a risk of injury from unintentionally pressing the on/off switch.

- Do not touch grinding and cutting discs until they have cooled down. The discs can become very hot while working. Clean the grinding spindle (18) and all the parts to be fitted. Lock the grinding spindle with the spindle lock button (3) before clamping and releasing the abrasive tools.

- Do not press the spindle lock button while the grinding spindle is moving. The power tool may become damaged if you do this. Grinding/Cutting Disc Pay attention to the dimensions of the grinding tools. The mounting hole diameter must fit the mounting flange without play. Do not use reducers or adapters. When using diamond cutting discs, pay attention that the direction-of-rotation arrow on the diamond cutting disc and the direction of rotation of the machine (see direction-of-rotation arrow on the machine head) agree. See the graphics page for the mounting sequence. To fasten the grinding/cutting disc, screw on the clamping nut (13) and tighten with the two-hole spanner.

- After fitting the abrasive tool, check that the abrasive tool is fitted correctly and can turn freely before switching on the power tool. Make sure that the abrasive tool does not brush against the protective guard or other parts.

Flap disc - Always fit the handguard (19) when working with the flap disc. Rubber Sanding Pad

- Always fit the handguard (19) when working with the rubber sanding pad (20). See the graphics page for fitting instructions. Slide the rubber sanding pad (20) onto the grinding spindle (18). Press the sanding sheet (21) firmly onto the underside of the rubber sanding pad (20). Screw on the round nut (22) and tighten with a two-pin spanner. Cup brush/disc brush

- Always fit the handguard (19) when working with the cup brush or disc brush. See the graphics page for fitting instructions. The cup brush/disc brush must be screwed onto the grinding spindle until it rests firmly against the grinding spindle flange at the end of the grinding spindle thread. Tighten the cup brush/disc brush with an open-ended spanner. Carbide Grinding Head

- A grinding head may be used only with a suitable protective guard. Approved abrasive tools You can use all the abrasive tools mentioned in these operating instructions. The permissible speed [min -1 ] or the circumferential speed [m/s] of the abrasive tools used must at least match the values given in the table. It is therefore important to observe the permissible rotational/circumferential peed on the label of the abrasive tool.

| max | [mm] | [mm] | |||

| D | b | d | [min -1 ] | [m/s] | |

| 100 | 7 | 16 | 11.000 | 80 | |

| 100 | – | – | 11.000 | 80 | |

| 75 | 30 | M14 | 11.000 | 80 | |

| 82 | – | M14 | 11.000 | 80 | |

Rotating the Machine Head (GWS 18V-15 C)

u Remove the battery from the power tool before carrying out work on the power tool (e.g. maintenance, changing tool, etc.). The battery should also be removed for transport and storage. There is risk of injury from unintentionally pressing the on/off switch.

The machine head can be rotated in 90° increments. In this way, the on/off switch can be brought into a more favorable handling position for particular applications, e.g. for lefthanded tool users. Completely unscrew the four screws. Rotate the ma chine head carefully, without removing it from the housing, into the new position. Screw-in and retighten the four screws.

Dust/Chip Extraction

Dust from materials such as lead-containing coatings, some wood types, minerals, and metal can be harmful to one’s health. Touching or breathing in the dust can cause allergic reactions and/or lead to respiratory infections of the user or bystanders. Certain dust, such as oak or beech dust, is considered carcinogenic, especially in connection with ood- treatment additives (chromate, wood preservative). Materials containing asbestos may only be worked by specialists.

– Provide for good ventilation of the working place.

– It is recommended to wear a P2 filter-class respirator. Observe the relevant regulations in your country for the materials to be worked.

Speed Preselection (GWS 18V-15 SC)

The factory settings include three preset speeds. Using a special application (Bosch Toolbox app), up to six-speed settings can be programmed.

- Avoid dust accumulation at the workplace. Dust can easily ignite.

Operation

Start-up

Inserting the battery

Push the charged battery (7) into the base of the power tool from the front until the battery is securely locked.

Switching on/off

To start the power tool, push the on/off switch (5) forward. To lock the on/off switch (5) in position, push the on/off switch (5) forward and down until it clicks into place. To switch off the power tool, release the on/off switch (5); or, if the switch is locked, briefly push the on/off switch (5) backward and down and then release it.

- Always check abrasive tools before using them. The abrasive tool must be fitted properly and be able to move freely. Carry out a test run for at least one minute with no load. Do not use abrasive tools that are damaged, run untrue, or vibrate during use. Damaged abrasive tools can burst apart and cause injuries.

If there is a sudden kickback in the power tool, e.g. jamming in a separating cut, the power supply to the motor will be interrupted electronically. The kickback stop indicator(26) then lights up. When the kickback stop is activated, the status indicator (30) flashes red. To restart the tool, set the on/off switch (5) to the off position and then switch the power tool on again.

Restart protection

The restart protection feature prevents the power tool from starting unintentionally after the power supply to it has been interrupted. When restart protection is activated, the status indicator (30) flashes red. To restart the tool, set the on/off switch (5) to the off position and then switch the power tool on again.

Impact shutdown

The integrated impact shutdown switches the power tool off as soon as it hits the floor. The status indicator (30) then flashes red. To restart the tool, set the on/off switch (5) to the off position and then switch the power tool on again.

User interface (see figure A)

The user interface (4) is used to preselect the speed and to indicate the status of the power tool. If the number of speeds is changed, the values of the preset individual speed settings are adjusted. In this case, the speed setting/mode indicator (28) lights up white. If a speed value is individually programmed, the speed setting/mode indicator (28)

lights up blue for this speed setting (i.e. does not correspond to a default setting). It is possible to individually adjust the speed settings in steps of 200 min -1. Keep in mind the logically ascending sequence of the settings (2 ≥ 1, 3 ≥ 2, etc.) when doing so. The following table shows the preset speeds (default settings) for each programmed number of settings.

| GWS 18V-15 SC | Basic speed setting at level | |||||

| 1 | 2 | 3 | 4 | 5 | 6 | |

| [min -1 ] | [min -1 ] | [min -1 ] | [min -1 ] | [min -1 ] | [min -1 ] | |

| Number of speed settings | ||||||

| 1 | 3400 | – | – | – | – | – |

| 2 | 3400 | 9800 | – | – | – | – |

| 3 | 3400 | 6600 | 9800 | – | – | – |

| 4 | 3400 | 5600 | 7600 | 9800 | – | – |

| 5 | 3400 | 5000 | 6600 | 8200 | 9800 | – |

| 6 | 3400 | 4600 | 6000 | 7200 | 8600 | 9800 |

The specified speed setting values depend on the rechargeable battery in use, the battery’s state of charge, and the tool’s operating temperature. You can use the button for speed preselection (27) to preselect the required speed, even during operation. The information in the table below describes the recommended values for the default settings with 3 preset speed levels.

| Material | Application | Application tool | Speed preselection level | GWS 18V-15 SC [min -1 ] |

| Metal | Brushing, removing rust | Cup brush | 1 | 3400 |

| Stainless steel | Grinding | Fiber disc | 2 | 6600 |

| Metal | Rough grinding | Grinding disc | 3 | max. |

| Metal | Cutting | Grinding disc | 3 | max. |

| Stone | Cutting | Diamond cutting disc and cutting guide (cutting of stone is permitted only with a cutting guide) |

3 | max. |

| The rated speed of the accessory must be at least equal to the maximum speed marked on the power | tool. Accessories running faster than their rated speed can break and fly apart. |

Status indications

| Battery charge indicator (user interface) (25) | Meaning/cause | Solution |

| Green | Battery charged | – |

| Yellow | Battery almost empty | Replace or charge battery soon |

| Red | Battery empty | Replace or charge the battery |

| Temperature indicator (31) | Meaning/cause | Solution |

| Yellow | Critical temperature has been reached (motor, electronics, battery) |

Run the power tool at no load and allow it to cool down |

| Red | A power tool is overheated and will switch off | Leave the power tool to cool down |

| Power tool status indicator (30) | Meaning/cause | Solution |

| Green | Status OK | |

| Yellow | Critical temperature has been reached or the battery is almost empty | Run the power tool at no load and allow it to cool down, or replace or charge the battery soon |

| Illuminated red | The power tool has overheated or the battery is empty | Allow the power tool to cool down, or replace or charge the battery |

| Flashing red | Kickback shutdown, restart protection, or impact shutdown has been triggered | Turn the power tool off and on again |

| Flashing blue | A power tool is connected to a mobile device or settings are being transferred |

Connectivity functions

In conjunction with the Bluetooth® Low Energy Module GCY 42, the following connectivity functions are available for the power tool:

– Registration and personalization

– Status check, the output of warning messages

– General information and settings

– Management

Read the corresponding operating instructions for information about the Bluetooth® Low Energy Module GCY 42. The connection of the power tool with the app must be confirmed by pressing the speed preselection button (27) on the user interface(4). The app requests this when connecting.

Practical advice

- With the Bluetooth® Low Energy Module GCY 42, the power tool is equipped with a radio interface. Local operating restrictions, e.g. in aircraft or hospitals, must be observed.

- In areas where the Bluetooth® wireless technology is not allowed to be used, the Bluetooth® Low Energy Module GCY 42 and the button cell must be removed.

- Exercise caution when cutting slots in structural walls; see the “Information on structural design” section.

- Clamp the workpiece if it is not secure under its own weight.

- Do not load the power tool so heavily that it comes to a stop.

- If the power tool has been subjected to a heavy load, continue to run it at no-load for several minutes to cool down the accessory.

- Do not use the power tool with a cut-off stand.

- Do not touch grinding and cutting discs until they have cooled down. The discs can become very hot while working. If the power tool becomes electrostatically charged, the built-in electronics will switch the power tool off. Press the on/off switch (5) again to restart the power tool. Rough grinding

- Never use cutting discs for rough grinding. The best rough grinding results are achieved with a set angle of 30° to 40°. Move the power tool back and forth with moderate pressure. This will ensure that the workpiece does not become too hot or discolored and that grooves are not formed.

Flap disc The flap disc (accessory) enables you to machine curved surfaces and profiles. Flap discs have a considerably longer service life, lower noise levels, and lower sanding temperatures than conventional grinding discs.

Cutting metal

- Always use the protective guard for cutting (15) when cutting bonded abrasives. When carrying out abrasive cutting, use a moderate feed that is suited to the material being machined. Do not exert pressure on the cutting disc and do not tilt or swing the power tool. Do not attempt to reduce the speed of a cutting disc coming to a stop by applying pressure from the side.

The power tool must always work in an up-grinding motion. Otherwise, there is a risk that it will be pushed uncontrolled out of the cut. For best results when cutting profiles and rectangular tubing, start at the smallest cross-section.

Cutting stone

- Provide sufficient dust extraction when cutting stone.

- Wear a dust mask.

- The power tool may be used only for dry cutting/grinding.

For best results when cutting stone, use a diamond cutting disc. When cutting especially hard materials such as concrete with a high pebble content, the diamond cutting disc can overheat and become damaged as a result. This is clearly indicated by circular sparking, rotating with the diamond cutting disc. If this happens, stop cutting and allow the diamond cutting disc to cool down by running the power tool for a short time at maximum speed with no load. Working noticeably slower and with circular sparking indicate that the diamond cutting disc has become dull. You

Licenses

Copyright © 2009–2016 ARM LIMITED

All rights reserved.

Redistribution and use in source and binary forms, with or without modification, are permitted provided that the following conditions are met:

– Redistributions of source code must retain the above copyright notice, this list of conditions, and the following disclaimer.

– Redistributions in binary form must reproduce the above copyright notice, this list of conditions, and the following disclaimer in the documentation and/or other materials provided with the distribution.

– Neither the name of ARM nor the names of its contributors may be used to endorse or promote products derived from this software without specific prior written permission.

THIS SOFTWARE IS PROVIDED BY THE COPYRIGHT HOLDERS AND CONTRIBUTORS “AS IS” AND ANY EXPRESS OR IMPLIED WARRANTIES, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR PARTICULAR PURPOSES ARE DISCLAIMED. IN NO EVENT SHALL THE COPYRIGHT OWNER OR CONTRIBUTORS BE LIABLE FOR ANY DIRECT, INDIRECT, INCIDENTAL, SPECIAL, EXEMPLARY, OR CONSEQUENTIAL DAMAGES (INCLUDING, BUT NOT LIMITED TO, PROCUREMENT OF SUBSTITUTE GOODS OR SERVICES; LOSS OF USE, DATA, OR PROFITS; OR BUSINESS INTERRUPTION) HOWEVER CAUSED AND ON ANY THEORY OF LIABILITY, WHETHER IN CONTRACT, STRICT LIABILITY, OR TORT (INCLUDING NEGLIGENCE OR OTHERWISE) ARISING IN ANY WAY OUT OF THE USE OF THIS SOFTWARE, EVEN IF ADVISED OF THE POSSIBILITY OF SUCH DAMAGE.

Copyright © 2016–2019 STMicroelectronics

All rights reserved.

Redistribution and use in source and binary forms, with or without modification, are permitted provided that the following conditions are met:

– Redistributions of source code must retain the above copyright notice, this list of conditions, and the following disclaimer.

– Redistributions in binary form must reproduce the above copyright notice, this list of conditions, and the following disclaimer in the documentation and/or other materials provided with the distribution.

– Neither the name of STMicroelectronics nor the names of its contributors may be used to endorse or promote products de- rived from this software without specific prior written permission.

THIS SOFTWARE IS PROVIDED BY THE COPYRIGHT HOLDERS AND CONTRIBUTORS “AS IS” AND ANY EXPRESS OR IMPLIED WARRANTIES, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR PARTICULAR PURPOSES ARE DISCLAIMED. IN NO EVENT SHALL THE COPYRIGHT OWNER OR CONTRIBUTORS BE LIABLE FOR ANY DIRECT, INDIRECT, INCIDENTAL, SPECIAL, EXEMPLARY, OR CONSEQUENTIAL DAMAGES (INCLUDING, BUT NOT LIMITED TO, PROCUREMENT OF SUBSTITUTE GOODS OR SERVICES; LOSS OF USE, DATA, OR PROFITS; OR BUSINESS INTERRUPTION) HOWEVER CAUSED AND ON ANY THEORY OF LIABILITY, WHETHER IN CONTRACT, STRICT LIABILITY, OR TORT (INCLUDING NEGLIGENCE OR OTHERWISE) ARISING IN ANY WAY OUT OF THE USE OF THIS SOFTWARE, EVEN IF ADVISED OF THE POSSIBILITY OF SUCH DAMAGE.

Robert Bosch Power Tools GmbH70538 Stuttgart

GERMANY

www.bosch-pt.com