Honeywell Miller Shock Absorber Supplement Instruction Manual

Honeywell Miller Shock Absorber SupplementInstruction Manual

Understanding Shock Absorber Differences

Miller Fall Protection is dedicated to product development and user needs, and therefore offers different shock absorber styles as well as produces that meet different performance specifications for personal shock absorbers and shock-absorbing lanyards. It is imperative to know and understand these differences to ensure safety on the jobsite.

Shock Absorber Styles

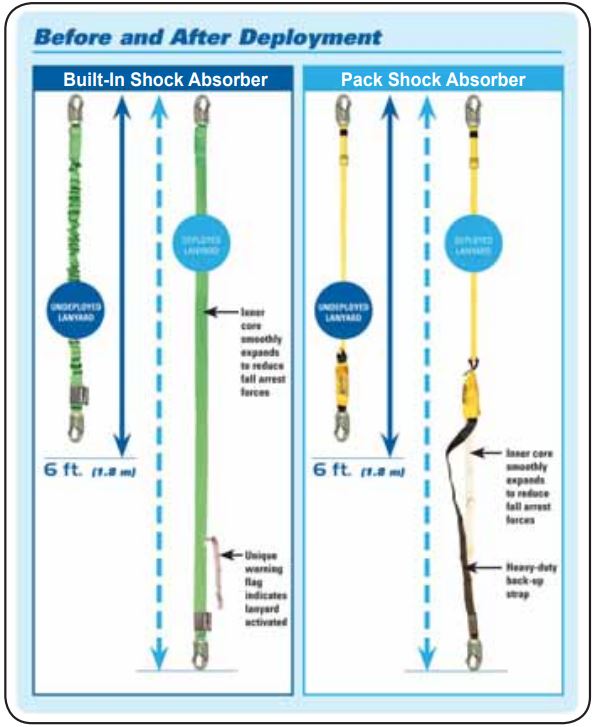

There are two primary Miller shock absorber styles for lanyards: built-in and pack.

- The built-in shock absorber is a specially-woven inner core within a tubular lanyard that smoothly expands to reduce fall arrest forces.

- The pack shock absorber is a readily visible component of the lanyard. Inside the pack is a specially-woven inner core that smoothly expands to reduce fall arrest forces as well as a heavy-duty back- Built-In Shock Absorber Pack Shock Absorber up safety strap.

Shock

Absorber

performance Specifications

Whether built-in or pack style, Miller personal shock absorbers and shock-absorbing lanyards fall into different performance categories. These differences are based on whether the shock absorber was designed for a specific user application 6ft. (1.83m) free fall or up to a potential 12 ft. (3.66m) free fall when deemed necessary: minimum and maximum worker weight capacities and or whether the shock absorber was engineered and tested to specific standers [ ANIZ359,1, ANSI Z359. 13, ANSI A10.32 or CSA Z259.11]

It is essential to refer to product labelling to determine the standards met by your particular product and relative specifications regarding capacities, allowable free fall, elongation characteristics and potential fall arrest forces.

The following table outlines shock absorber performance specifications required based on ANSI and CSA standards.

Important Notes

- All Miller personal shock absorbers and shock-absorbing lanyards are OSHA compliant.

- When a product is marked as meeting more than one standard , the performance specifications of the most stringent of the requirements are listed on the labelling.

- Table is based on ambient dry conditioning test performance requirements. for additional condition theist requirements, refer to the standard. [Miller Fall Protection also provides an ANZI Z359. 13-2009 informational supplement, available at www.millerfallprotection.com, to incise awareness and gain understanding of this recent ANSI standard and its design and testing requirements.]

*The ANSI Z359.13-2009 standard increased the steel test weight used by manufacturers to test personal shock absorbers and shock-absorbing lanyards from 220 to 282 lbs. (100-128kg). Because of the heavier test weight requirement, the ANSI standard now allows for greater shock absorber elongation.

**The ANSI Z359.13 standard addresses design and performance requirements for double-pack shock absorbers, such as the Miller MAX shock absorbers and Titan X2 shock absorbers, which may be used for a 12-foot (3.66m) free fall situation. Alternative means of fall protection should always be investigated prior to using systems that allow for free falls greater than 6 ft. (1.83m). [Note: Miller MAX and Titan X2 shock absorbers may also be used for workers weighing between 311 lbs. (141kg) and 400 lbs. (181.4kg), but free fall must be limited to 6 ft. (1.83m) or less in this application.]

***Average arrest force of Miller E4 shock absorbers: 874 lbs. (3.8kN); Average arrest force of Miller E6 shock absorbers: 1250 lbs. (5.6kN)

MAXIMUM CAPACITY WARNING: If the system is used by an employee having a combined tool and body weight between 310 lbs. (140.6 kg) and 400 lbs. (181.4 kg), then the employer must appropriately modify the criteria and protocols to provide proper protection for such heavier weights, or the system will not be deemed to be in compliance with the requirements of OSHA 1926.502(d)(16).

ANSI Z359.13 WARNING: If the labels and/or instructions of other Miller Fall Protection products and systems indicate that they are only to be used with personal fall arrest equipment that limits maximum fall arrest forces to 900 lbs. (4kN) or less, do not use with new ANSI Z359.13-2009 compliant product until otherwise authorized to do so by Miller Fall Protection. Contact Miller Technical Services for further information.

If there are any questions regarding the differences between Miller shock absorbers and shock- absorbing products and their specified performance characteristics, Please contact Miller Technical Services before using the equipment.

Calculating Fall Clearance Distance

It is essential to understand how to calculate potential fall clearance for each work application to avoid contact with a lower level. Use the following calculation to determine Required Fall Clearance.

Shock -Absorbing Lanyard Fall Clearance Calculation [Calculation taken from connection point of lanyard to anchorage or anchorage connector] Length of Lanyard

+ Maximum Elongation/Deceleration Distance

+ 1 ft. (.3m) Harness Stretch/Sliding Back D-Ring Movement

+ Height to worker’s Back D-Ring

+ 3 ft. (.9m) Safety Factor

__________________________

= Required Fall Clearance

NOTE: A fall clearance calculation made from the anchor point must take into consideration the length of the anchorage connector being used.

Sample Calculation

The following illustration demonstrates a sample calculation using a shock-absorbing lanyard. When actually calculating fall clearance distance, the authorized person/user must consider all variables, elongation of the lanyard, and the anchorage connector used, and then make necessary adjustments to the calculation.

If there is any question about calculating fall clearance distance, please contact Miller Fall Protection Technical Services Department at 1-800-873-5242

Toll Free: 800.873.5242

Fax: 800.892.4078

Download this manual at: www.millerfallprotection.com

Honeywell Safety Products

P.O Box 271, 1345 15th Street

Franklin, PA 16323 USA